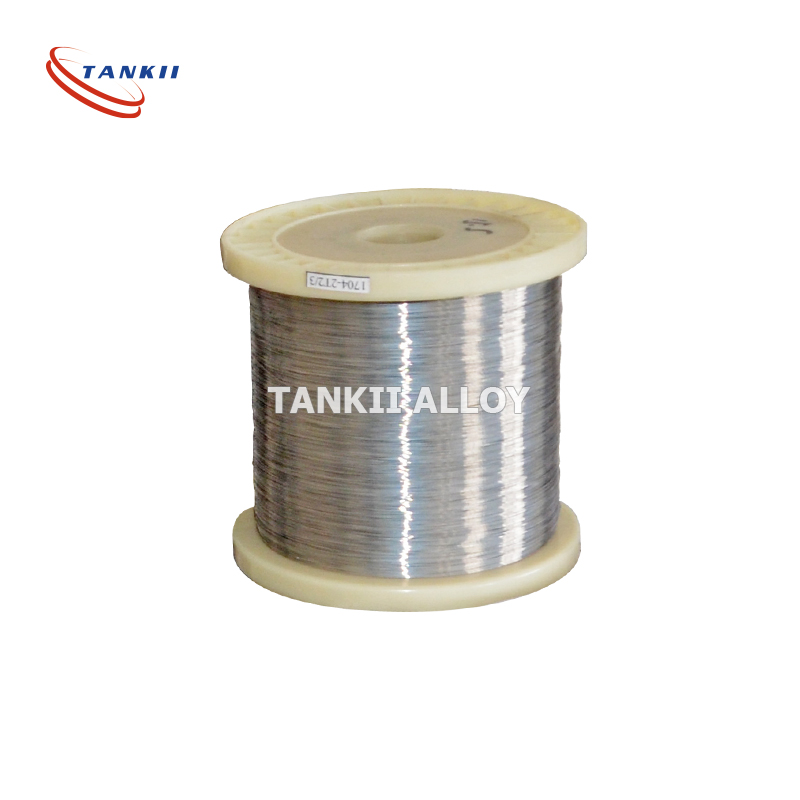

Intambo Yokumelana Ne-Alloy ye-FeCrAl engu-0.05mm Kuya ku-10mm Esetshenziselwa Izinto Zokushisa (I-CrAl 25/5)

Intambo Yokumelana Nokushisa/Umkhiqizi WaseShayina

Ukuhlaziywa Okujwayelekile

20.00 Cr, 5.00 Al, i-Bal. Fe

Izinga lokushisa eliphezulu lokusebenza: 1250 ºC.

Izinga Lokushisa Lokuncibilika: 1500 º C

Ukumelana kukagesi: 1.4 ohm mm2/m

Kusetshenziswe kakhulu njengezinto zokushisa ezithandweni zezimboni kanye nasezindlini zikagesi.

Inamandla okushisa amancane kune-Tophet alloys kodwa inephuzu lokuncibilika eliphakeme kakhulu.

Inkampani engu-Shanghai TANKII ALLOY MATERIAL Co., Ltd.

UMKHIQIZISI WE-ALCHROME NE-FECRAL ALLOY ONGUCHWEPHESHE KAKHULU E-China

Siphinde sikhiqize i-CrAl 14/4, i-CrAl 19/3 kanye nezinye izintambo zokumelana nezinga ezidingwa yizimboni.

| Ukwakheka Kwamakhemikhali kanye Nempahla Eyinhloko Ye-Fe-Cr-Al Resistance Alloy | | Izakhiwo \ Ibanga | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | Ukwakheka Okuyinhloko Kwamakhemikhali

(%) | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 22.5-24.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 | | Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.0 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | | Re | ithuba | ithuba | ithuba | ithuba | ithuba | ithuba | ithuba | | Fe | Ibhalansi. | Ibhalansi. | Ibhalansi. | Ibhalansi. | Ibhalansi. | Ibhalansi. | Ibhalansi. | | | | | | | Inombolo 0.5 | UMsombuluko 1.8-2.2 | | Izinga Lokushisa Eliphezulu Lesevisi Eqhubekayo (oC) | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | | Ukuqina kokuqina 20oC (Ω mm2/m) | 1.25

± 0.08 | 1.42

± 0.06 | 1.42

± 0.07 | 1.35

± 0.07 | 1.23

± 0.07 | 1.45

± 0.07 | 1.53

± 0.07 | | Ubuningi (g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | | Ukuqhuba Okushisayo | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | 45.2 | | (KJ/m@ h@ oC) | | I-Coefficient Yokwanda Kokushisa (α × 10-6/oC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | | Isilinganiso Sokuncibilika (oC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | | Amandla Okuqina (N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | | Ukwelulwa (%) | > 16 | > 12 | > 12 | > 12 | > 12 | > 12 | > 10 | | Ukwehluka Kwesigaba | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | | Izinga Lokuncipha (%) | | Imvamisa Yokugoba Ngokuphindaphindiwe (F/R) | > 5 | > 5 | > 5 | > 5 | > 5 | > 5 | > 5 | | Ubulukhuni (HB) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | | Isikhathi Sesevisi Esiqhubekayo | no | ≥ 80/1300 | ≥ 80/1300 | ≥ 80/1300 | ≥ 80/1250 | ≥ 50/1350 | ≥ 50/1350 | | Isakhiwo se-Micrographic | I-Ferrite | I-Ferrite | I-Ferrite | I-Ferrite | I-Ferrite | I-Ferrite | I-Ferrite | | Impahla Kamagnetic | Uzibuthe | Uzibuthe | Uzibuthe | Uzibuthe | Uzibuthe | Uzibuthe | Uzibuthe | |

Okwedlule: Isibani se-Quartz Isifudumezi se-Carbon Infrared Lamp Amabhaluni e-Infrared Amhlophe Ishubhu le-Infrared Olandelayo: Intambo ye-Aluminium ye-Iron Chrome (CrAl 25-5) engu-0.5mm ene-DIN250 spool