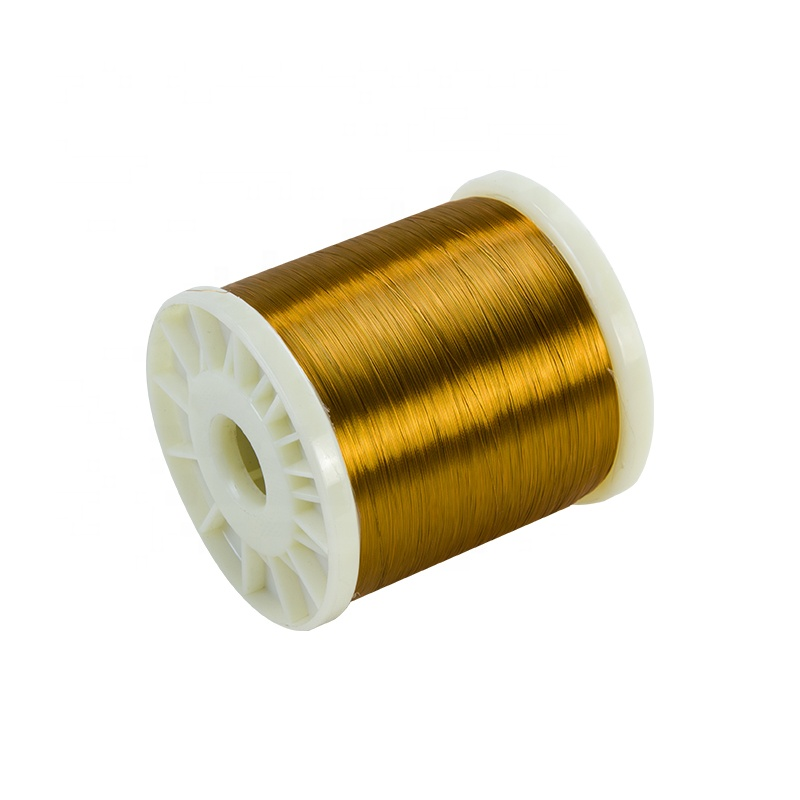

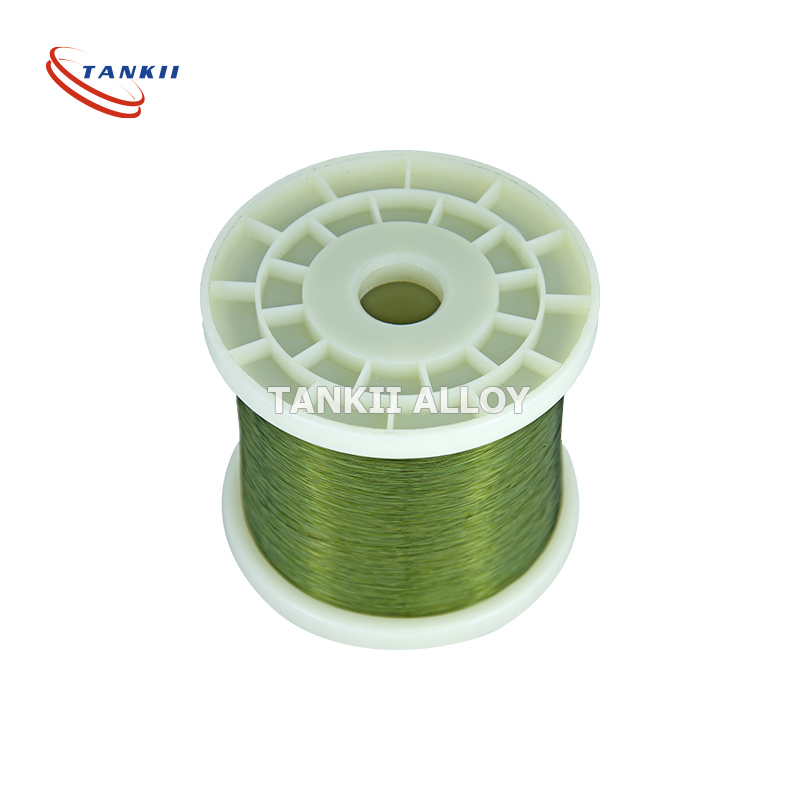

I-Manganin ye-Copper Alloy eyindilinga engu-0.2mm Class 130 Enameled Wire

I-130 Class Colored Copper Alloy Manganin Enameled Wire

1. Incazelo Ejwayelekile Yezinto Ezibalulekile

I-alloy ye-nickel yethusi, enokumelana okuphansi kukagesi, imelana nokushisa nokugqwala okuhle, kulula ukuyicubungula futhi ihlanganiswe nge-lead. Isetshenziselwa ukwenza izingxenye ezibalulekile ku-relay yokushisa ngokweqile, i-thermal circuit breaker ephansi ukumelana, kanye nezinto zikagesi. Futhi iyinto ebalulekile yekhebula lokushisa likagesi. Ifana ne-s type cupronickel. Uma i-Nickel ihlanganiswa kakhulu, kulapho ubuso bumhlophe khona ngesiliva.

3. Ukwakheka Kwamakhemikhali kanye Nempahla Eyinhloko Ye-Cu-Ni Low Resistance Alloy

| I-PropertiesGrade | I-CuNi1 | I-CuNi2 | I-CuNi6 | I-CuNi8 | I-CuMn3 | I-CuNi10 | |

| Ukwakheka Okuyinhloko Kwamakhemikhali | Ni | 1 | 2 | 6 | 8 | _ | 10 |

| Mn | _ | _ | _ | _ | 3 | _ | |

| Cu | I-Bal | I-Bal | I-Bal | I-Bal | I-Bal | I-Bal | |

| Izinga Lokushisa Eliphezulu Lesevisi Eqhubekayo (oC) | 200 | 200 | 200 | 250 | 200 | 250 | |

| Ukuqina kokushisa ku-20oC (Ωmm2/m) | 0.03 | 0.05 | 0.10 | 0.12 | 0.12 | 0.15 | |

| Ubuningi (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.8 | 8.9 | |

| Ukushisa Okushisayo (α×10-6/oC) | <100 | <120 | <60 | <57 | <38 | <50 | |

| Amandla Okudonsa (i-Mpa) | ≥210 | ≥220 | ≥250 | ≥270 | ≥290 | ≥290 | |

| I-EMF vs Cu(μV/oC)(0~100oC) | -8 | -12 | -12 | -22 | _ | -25 | |

| Isilinganiso Sokuncibilika (oC) | 1085 | 1090 | 1095 | 1097 | 1050 | 1100 | |

| Isakhiwo se-Micrographic | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | |

| Impahla Kamagnetic | hhayi | hhayi | hhayi | hhayi | hhayi | hhayi | |

| I-PropertiesGrade | I-CuNi14 | I-CuNi19 | I-CuNi23 | I-CuNi30 | I-CuNi34 | I-CuNi44 | |

| Ukwakheka Okuyinhloko Kwamakhemikhali | Ni | 14 | 19 | 23 | 30 | 34 | 44 |

| Mn | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| Cu | I-Bal | I-Bal | I-Bal | I-Bal | I-Bal | I-Bal | |

| Izinga Lokushisa Eliphezulu Lesevisi Eqhubekayo (oC) | 300 | 300 | 300 | 350 | 350 | 400 | |

| Ukuqina kokushisa ku-20oC (Ωmm2/m) | 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.49 | |

| Ubuningi (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| Ukushisa Okushisayo (α×10-6/oC) | <30 | <25 | <16 | <10 | <0 | <-6 | |

| Amandla Okudonsa (i-Mpa) | ≥310 | ≥340 | ≥350 | ≥400 | ≥400 | ≥420 | |

| I-EMF vs Cu(μV/oC)(0~100oC) | -28 | -32 | -34 | -37 | -39 | -43 | |

| Isilinganiso Sokuncibilika (oC) | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| Isakhiwo se-Micrographic | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | |

| Impahla Kamagnetic | hhayi | hhayi | hhayi | hhayi | hhayi | hhayi | |

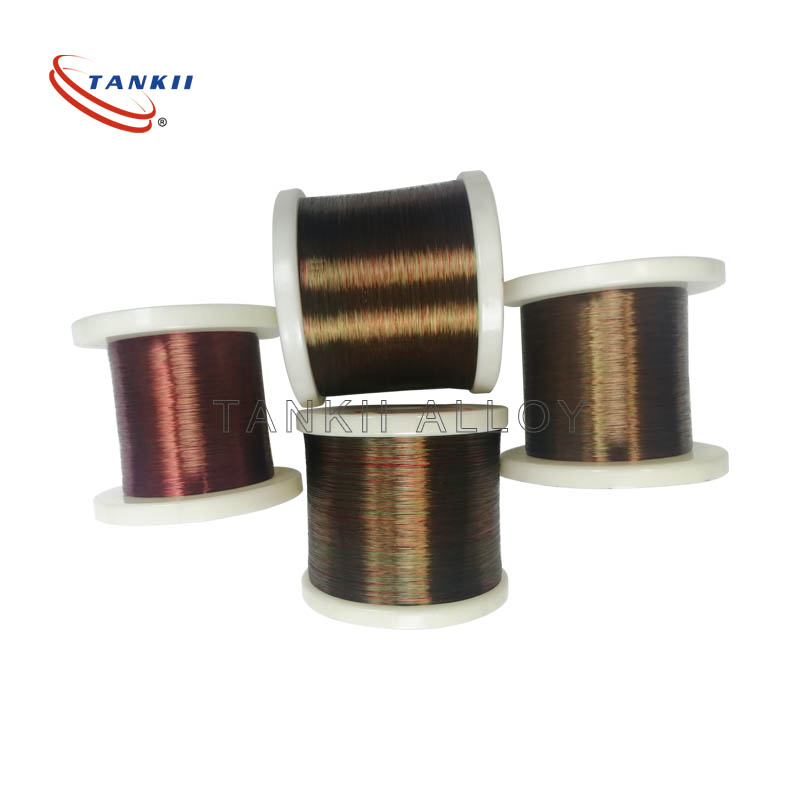

2. Isingeniso kanye nezinhlelo zokusebenza ze-Enamel Wire

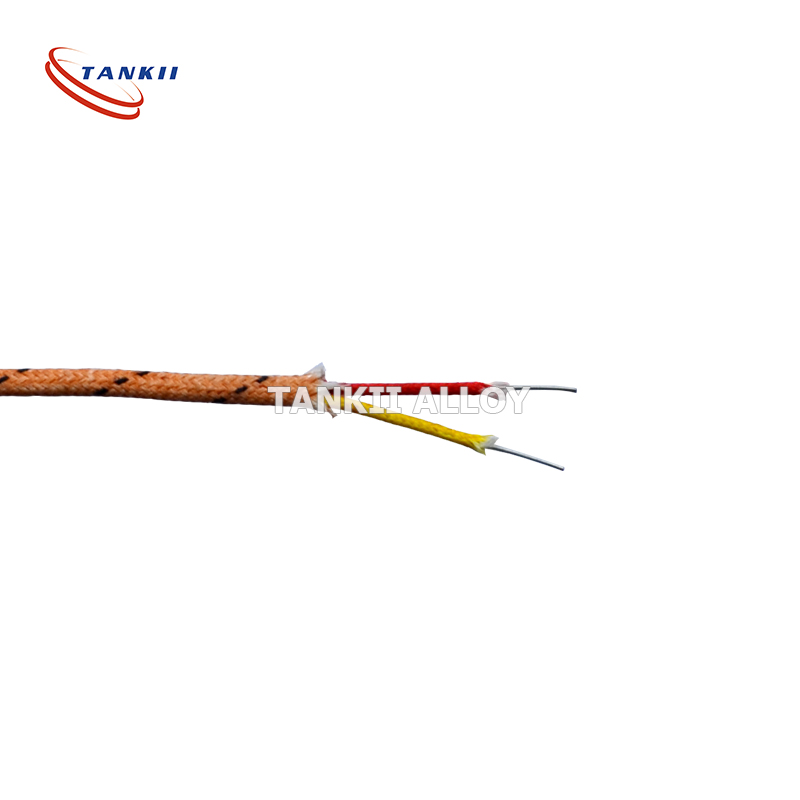

Nakuba kuchazwa ngokuthi “kufakwe enameled”,ucingo olune-enamelEqinisweni, ayimboziwe ngesendlalelo sopende we-enamel noma nge-vitreous enamel eyenziwe nge-fused glass powder. Intambo yamanje yemagnet ngokuvamile isebenzisa isendlalelo esisodwa kuya kwezine (uma kwenzeka intambo yohlobo lwe-quad-film) yokufakwa kwefilimu ye-polymer, ngokuvamile yezinhlobo ezimbili ezihlukene, ukuhlinzeka ngesendlalelo sokufakwa kwe-polymer esiqinile, esiqhubekayo. Amafilimu okufakwa kwe-magnet wire asebenzisa (ngokulandelana kokuphakama kwezinga lokushisa) i-polyvinyl formal (Formar), i-polyurethane, i-polyimide, i-polyamide, i-polyamide, i-polyster, i-polyester-polyimide, i-polyamide-polyimide (noma i-amide-imide), kanye ne-polyimide. Intambo yemagnet efakwe i-polyimide iyakwazi ukusebenza kufika ku-250 °C. Ukufakwa kwentambo yemagnet eyisikwele noma engunxande ejiyile kuvame ukwandiswa ngokuyisonga nge-polyimide noma i-fiberglass tape enokushisa okuphezulu, futhi ukugoqa okuqediwe kuvame ukufakwa nge-vacuum nge-varnish yokufakwa kwe-insulating ukuze kuthuthukiswe amandla okufakwa kwe-insulating kanye nokuthembeka kwesikhathi eside kokugoqa.

Amakhoyili azisekelayo aboshwe ngocingo olumbozwe okungenani ngezingqimba ezimbili, ingxenye engaphandle iyi-thermoplastic ebopha amajika ndawonye lapho eshiswa.

Ezinye izinhlobo zokuvikela ukushisa ezifana nentambo ye-fiberglass ene-varnish, iphepha le-aramid, iphepha le-kraft, i-mica, kanye nefilimu ye-polyester nazo zisetshenziswa kabanzi emhlabeni wonke ngezinhlelo zokusebenza ezahlukahlukene njenge-transformers kanye nama-reactor. Emkhakheni womsindo, ucingo lwesiliva olwakhiwe, kanye nezinye izinto zokuvikela ukushisa ezahlukahlukene, njengokotini (ngezinye izikhathi olugcwele uhlobo oluthile lwe-coagulating agent/thickener, njenge-beewax) kanye ne-polytetrafluoroethylene (PTFE) kungatholakala. Izinto zokuvikela ukushisa ezindala zazihlanganisa ukotini, iphepha, noma usilika, kodwa lezi ziwusizo kuphela ekusetshenzisweni kwezinga lokushisa eliphansi (kufika ku-105°C).

Ukuze kube lula ukukhiqiza, ucingo oluthile olusebenzisa amandla kagesi olusezingeni eliphansi lune-insulation engasuswa ngokushisa kwe-soldering. Lokhu kusho ukuthi ukuxhumeka kukagesi emaphethelweni kungenziwa ngaphandle kokususa i-insulation kuqala.

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu