Siyakwamukela kumawebhusayithi ethu!

Intambo ye-1j76 Ni76Cr2Cu5 Soft Magnetic Alloys ene-High Initial Permeability

Ukwakheka okuvamile%

| Ni | 75~76.5 | Fe | Ibhalansi. | Mn | 0.3~0.6 | Si | 0.15~0.3 |

| Mo | - | Cu | 4.8~5.2 | Cr | 1.8~2.2 | ||

| C | ≤0.03 | P | ≤0.02 | S | ≤0.02 |

Izakhiwo Ezijwayelekile Zemishini

| Amandla okukhiqiza | Amandla Okudonsa | Ukwelulwa |

| I-Mpa | I-Mpa | % |

| 980 | 1030 | 3~50 |

Izakhiwo Ezijwayelekile Zomzimba

| Ubuningi (g/cm3) | 8.6 |

| Ukumelana kukagesi ku-20ºC(Om*mm2/m) | 0.55 |

| I-Coefficient yokwanda okuqondile (20ºC ~ 200ºC)X10-6/ºC | 10.3~11.5 |

| I-coefficient ye-magnetostriction yokugcwala λθ/ 10-6 | 2.4 |

| Iphuzu le-Curie Tc/ºC | 400 |

Izakhiwo zikagesi zama-alloy anokuvuleka okuphezulu emasimini abuthakathaka | |||||||

| 1J76 | Ukuvuleka kokuqala | Ukuvuleka okuphezulu | Ukuphoqelela | Ukuqina kokungeniswa kwamagnetic okugcwala | |||

| Ishidi/umugqa ogoqwe kudala. Ubukhulu, mm | μ0.08/ (mH/m) | μm/ (mH/m) | I-Hc/ (A/m) | I-BS/ T | |||

| ≥ | ≤ | ||||||

| 0.01 mm | 17.5 | 87.5 | 5.6 | 0.75 | |||

| 0.1~0.19 mm | 25.0 | 162.5 | 2.4 | ||||

| 0.2~0.34 mm | 28.0 | 225.0 | 1.6 | ||||

| 0.35~1.0 mm | 30.0 | 250.0 | 1.6 | ||||

| 1.1 ~ 2.5 mm | 27.5 | 225.0 | 1.6 | ||||

| 2.6~3.0 mm | 26.3 | 187.5 | 2.0 | ||||

| ucingo oludonswe ngokubandayo | |||||||

| 0.1 mm | 6.3 | 50 | 6.4 | ||||

| Ibha | |||||||

| 8-100 mm | 25 | 100 | 3.2 | ||||

| Indlela yokwelashwa ngokushisa 1J76 | |

| Imidiya yokuhlanganisa | Vacuum enengcindezi eseleyo engekho ngaphezu kuka-0.1Pa, i-hydrogen enephuzu lamazolo elingaba ngaphezu kuka-40 ºC. |

| Izinga lokushisa kanye nesilinganiso | 1100~1150ºC |

| Isikhathi sokubamba | 3~6 |

| Izinga lokupholisa | Uma ipholile ngo-100 ~ 200 ºC/h ifinyelela ku-600 ºC, iphole ngokushesha ifinyelela ku-300ºC |

Bhala umlayezo wakho lapha bese uwuthumela kithi

Izigaba zemikhiqizo

-

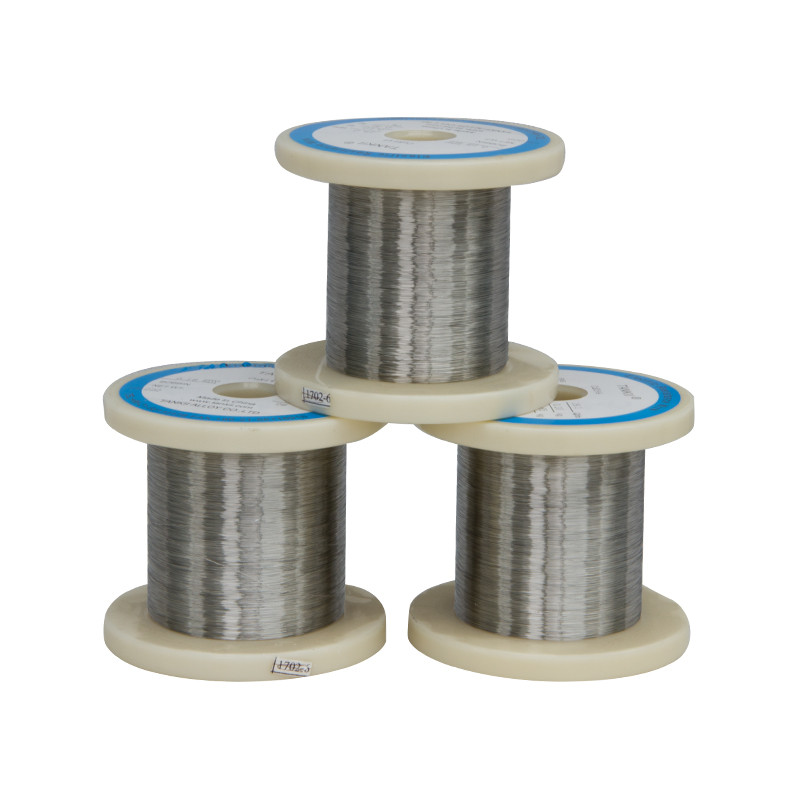

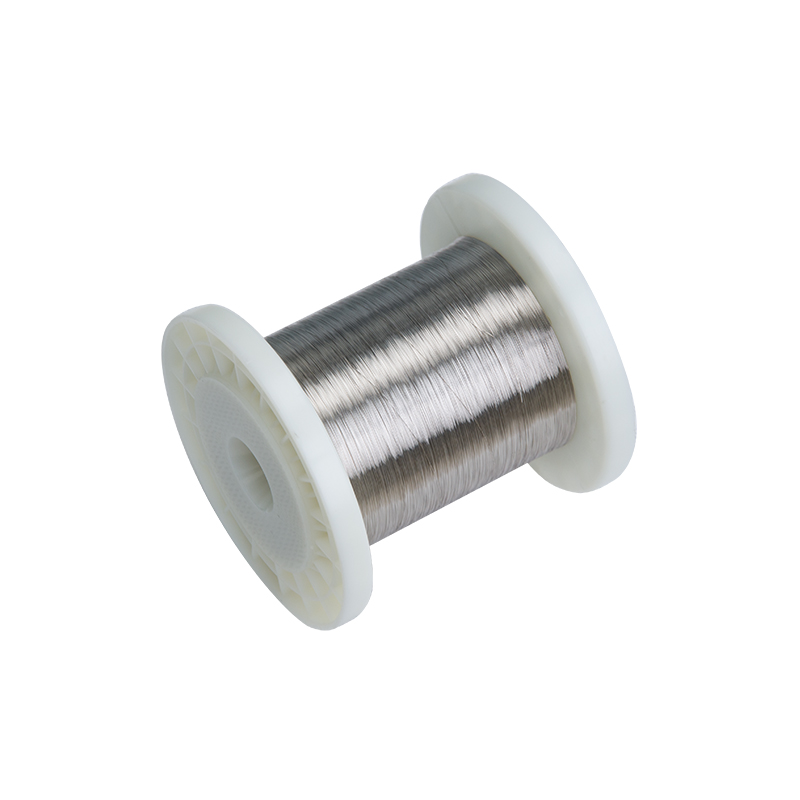

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu