I-4j36 Invar Alloy Wire I-Alloy Yokukhulisa Okuphansi I-Feni36 Wire

4J36 (I-Invar) isetshenziswa lapho kudingeka khona ukuzinza okuphezulu, njengezinsimbi zokucacisa, amawashi, ama-seismic creep gauges, ozimele be-shadow-mask kamabonakude, ama-valve kuma-motor, kanye namawashi alwa ne-magnetic. Ekuhlolweni komhlaba, lapho kufanele kwenziwe i-first-order (high-precision) elevation leveling leaving, i-Level staff (induku yokulinganisa) esetshenziswayo yenziwe nge-Invar, esikhundleni sokhuni, i-fiberglass, noma ezinye izinsimbi. Ama-Invar struts asetshenziswa kwamanye ama-piston ukuze anciphise ukwanda kwawo kokushisa ngaphakathi kwama-cylinder awo.

I-4J36 isebenzisa ukushisela kwe-oxyacetylene, ukushisela kwe-arc kagesi, ukushisela kanye nezinye izindlela zokushisela. Njengoba i-coefficient yokwanda kanye nokwakheka kwamakhemikhali kwe-alloy kuhlobene kufanele kugwenywe ngenxa yokuthi ukushisela kubangela ushintsho ekwakhekeni kwe-alloy, kungcono ukusebenzisa i-Argon arc welding welding filler metals okungcono ukuthi iqukethe i-titanium engu-0.5% kuya ku-1.5%, ukuze kuncishiswe ukugoba kwe-weld kanye nokuqhekeka.

Ukwakheka okuvamile%

| Ni | 35~37.0 | Fe | Ibhalansi. | Co | - | Si | ≤0.3 |

| Mo | - | Cu | - | Cr | - | Mn | 0.2~0.6 |

| C | ≤0.05 | P | ≤0.02 | S | ≤0.02 |

Isilinganiso sokunwetshwa

| θ/ºC | α1/10-6ºC-1 | θ/ºC | α1/10-6ºC-1 |

| 20~-60 | 1.8 | 20~250 | 3.6 |

| 20~-40 | 1.8 | 20~300 | 5.2 |

| 20~-20 | 1.6 | 20~350 | 6.5 |

| 20~-0 | 1.6 | 20~400 | 7.8 |

| 20~50 | 1.1 | 20~450 | 8.9 |

| 20~100 | 1.4 | 20~500 | 9.7 |

| 20~150 | 1.9 | 20~550 | 10.4 |

| 20~200 | 2.5 | 20~600 | 11.0 |

Izakhiwo Ezijwayelekile Zomzimba

| Ubuningi (g/cm3) | 8.1 |

| Ukumelana kukagesi ku-20ºC(OMmm2/m) | 0.78 |

| Ithempelesha yokumelana nengcindezi(20ºC~200ºC)X10-6/ºC | 3.7~3.9 |

| Ukushisa, λ/ W/(m*ºC) | 11 |

| Iphuzu le-Curie Tc/ºC | 230 |

| I-Elastic Modulus, E/ Gpa | 144 |

| Inqubo yokwelapha ukushisa | |

| Ukuhlanza ukucindezeleka | Kushiswe kufike ku-530~550ºC bese ubamba ihora eli-1~2. Kubanda |

| ukubopha | Ukuze kuqedwe ukuqina, okumele kukhishwe ngenqubo yokudonsa ebandayo negoqiwe. Ukufaka i-Annealing kudinga ukushiswa kufikela ku-830 ~ 880ºC ku-vacuum, gcina imizuzu engama-30. |

| Inqubo yokuzinzisa |

|

| Izinyathelo zokuzivikela |

|

Izakhiwo Ezijwayelekile Zemishini

| Amandla Okudonsa | Ukwelulwa |

| I-Mpa | % |

| 641 | 14 |

| 689 | 9 |

| 731 | 8 |

Isici sokushisa sokumelana

| Ibanga lokushisa, ºC | 20~50 | 20~100 | 20~200 | 20~300 | 20~400 |

| aR/ 103 *ºC | 1.8 | 1.7 | 1.4 | 1.2 | 1.0 |

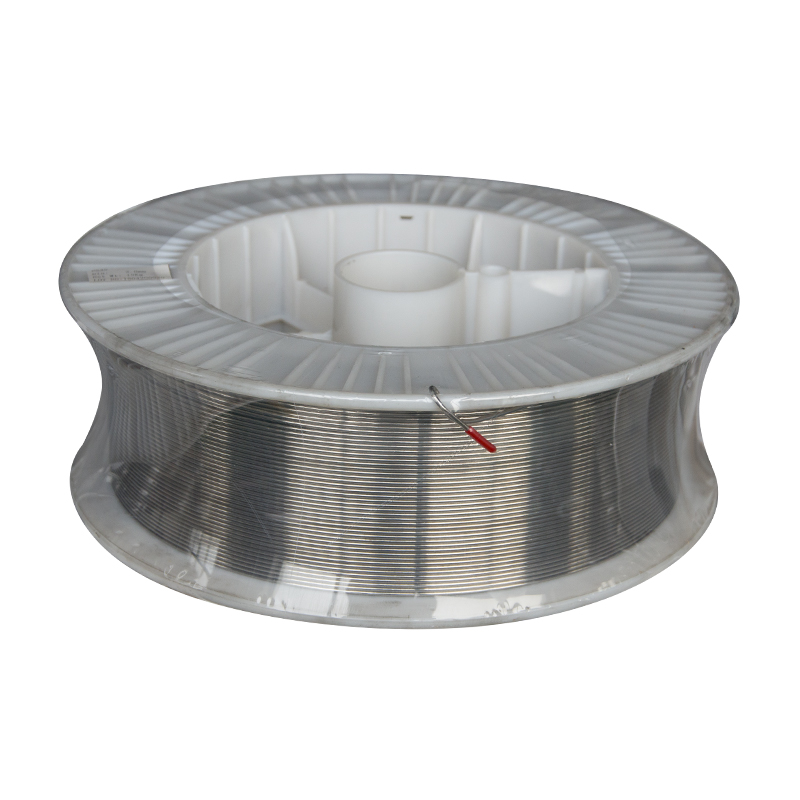

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu