I-Alkrothal 720 No.1 JR FeCrAl Alloy yokumelana namabhuleki

I-Alkrothal 720 Inombolo 1 JRyokumelana namabhuleki

Izicelo ezijwayelekile ze-Alkrothal 720 zitholakala kuma-rheostats, kuma-resistors okubhuleka, njll. Iphinde isetshenziswe njengezinto zokushisa zikagesi ezisetshenziswa ezimbonini.

I-Alkrothal 720 iyi-ferritic iron-chromium-aluminium alloy (i-FeCrAl alloy) esetshenziswa emazingeni okushisa afinyelela ku-1000°C (1830°F).

Ukuhlaziywa Okujwayelekile

| Cr | Al | Fe |

| 12.0~15.0 | 4.0~6.0 | Ibhalansi |

Izakhiwo Zemishini

| Izinga Lokushisa Eliphezulu Lesevisi Eqhubekayo: Ukuqina kokushisa okungu-20ºC: Ubuningi: Ukuqhuba Ukushisa: Isilinganiso Sokwanda Kokushisa: Indawo Yokuncibilika: Ukwelulwa: Isakhiwo se-Micrographic: Impahla Kamagnetic: | 950ºC 1.25ohm mm2/m 7.40g/cm3 52.7 KJ/m·h·ºC 15.4×10-6/ºC (20ºC~1000ºC) 1450ºC Ubuncane be-16% I-Ferrite amandla kazibuthe |

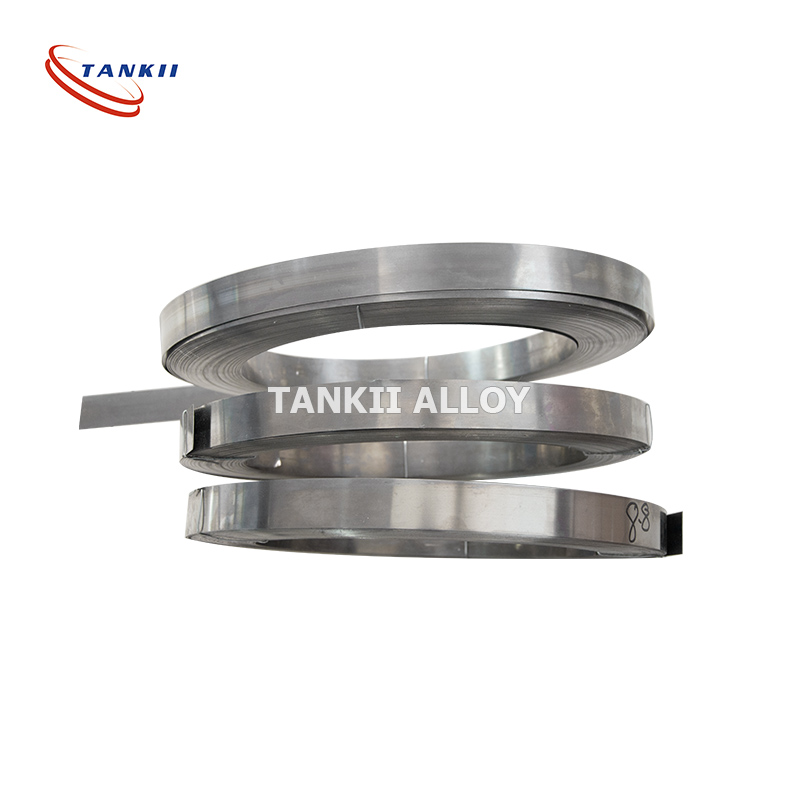

Usayizi: Ubukhulu 0.01-7mm, ububanzi 0.5-1000mm

Ubuso: BA, 2B

Ubulukhuni: Buthambile, Ubunzima obuyingxenye, bunzima

Kusetshenziswe kabanzi njenge-resisor enkulu yamabhuleki kanye nezinto zokushisa zesithando somlilo.

Inamandla okushisa amancane kune-Tophet alloys kodwa inephuzu lokuncibilika eliphakeme kakhulu.

Inkampani engu-Shanghai TANKII ALLOY MATERIAL Co., Ltd.

UMKHIQIZISI WE-FECRAL NE-ALCHROME ALLOY E-China, ONGUCHWEPHESHE OBUNINGI EMHLABENI

Siphinde sikhiqize amamaki angaphansi kwalawa:

0Cr15Al5 kanye no-0Cr19Al3, njll.

| Ukwakheka Kwamakhemikhali kanye Nempahla Eyinhloko Ye-Fe-Cr-Al Resistance Alloy | ||||||||

| Ibanga Lezakhiwo | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| Ukwakheka Okuyinhloko Kwamakhemikhali (%) | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 22.5-24.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.0 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| Re | ithuba | ithuba | ithuba | ithuba | ithuba | ithuba | ithuba | |

| Fe | Ibhalansi. | Ibhalansi. | Ibhalansi. | Ibhalansi. | Ibhalansi. | Ibhalansi. | Ibhalansi. | |

| Inombolo 0.5 | UMsombuluko 1.8-2.2 | |||||||

| Izinga Lokushisa Eliphezulu Lesevisi Eqhubekayo (oC) | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| Ukuqina kokuqina 20oC (Ωmm2/m) | 1.25 ±0.08 | 1.42 ±0.06 | 1.42 ±0.07 | 1.35 ±0.07 | 1.23 ±0.07 | 1.45 ±0.07 | 1.53 ±0.07 | |

| Ubuningi (g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

| Ukuqhuba Okushisayo | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | 45.2 | |

| (KJ/m@h@oC) | ||||||||

| I-Coefficient Yokwanda Kwe-Thermal (α×10-6/oC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

| Isilinganiso Sokuncibilika (oC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| Amandla Okuqina (N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| Ukwelulwa (%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| Ukwehluka Kwesigaba | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| Izinga Lokuncipha (%) | ||||||||

| Imvamisa Yokugoba Ngokuphindaphindiwe (F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| Ubulukhuni (HB) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| Isikhathi Sesevisi Esiqhubekayo | no | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥50/1350 | ≥50/1350 | |

| Isakhiwo se-Micrographic | I-Ferrite | I-Ferrite | I-Ferrite | I-Ferrite | I-Ferrite | I-Ferrite | I-Ferrite | |

| Impahla Kamagnetic | Uzibuthe | Uzibuthe | Uzibuthe | Uzibuthe | Uzibuthe | Uzibuthe | Uzibuthe | |

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu