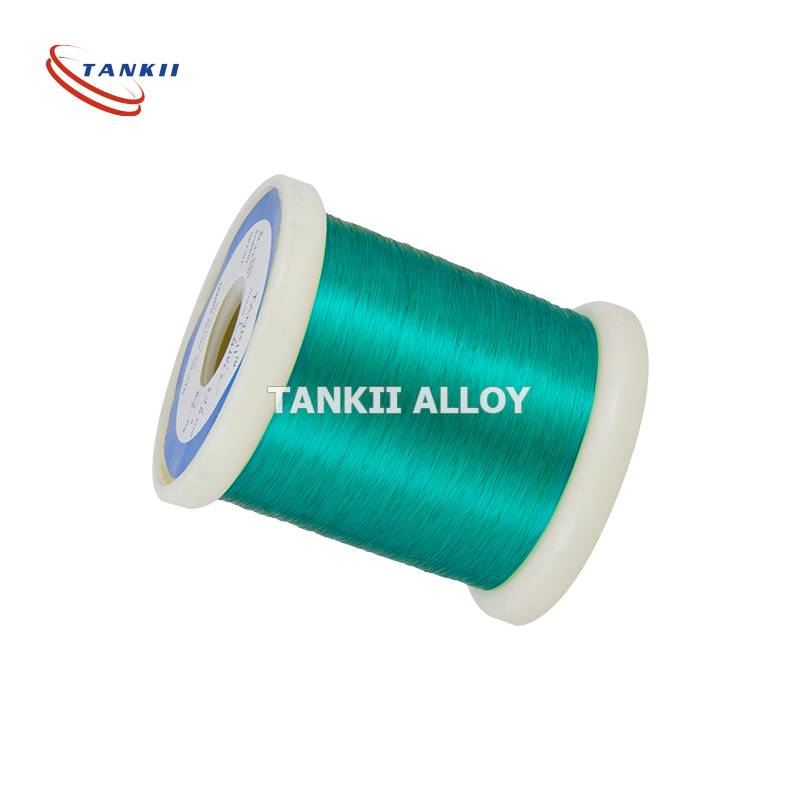

Ucingo lwethusi oluyindilinga oluyi-Class F olune-enamel/i-polyester eguquliwe

Iklasi Finayiloni/i-polyester eguquliwe enamel eyindilingaucingo lwethusi

Incazelo Yomkhiqizo

Lezi zintambo zokumelana ezihlanganisiwe zisetshenziswe kabanzi kuma-resistor ajwayelekile, izimoto

izingxenye, ama-resistors ajikelezayo, njll. esebenzisaukuvikela ukushisaukucubungula okufanelekela kakhulu lezi zinhlelo zokusebenza, kusetshenziswa ngokugcwele izici ezihlukile zokugqoka kwe-enamel.

Ngaphezu kwalokho, sizosebenzisa i-enamel coating.ukuvikela ukushisaucingo lwensimbi eyigugu njengesiliva nentambo yeplatinum uma u-oda. Sicela usebenzise lokhu kukhiqiza-ngoku-oda.

Uhlobo lwentambo ye-alloy engenalutho

Ingxubevange esingayenza enamelled yi-Copper-nickel alloy wire, i-Constantan wire, i-Manganin wire. I-Kama Wire, i-NiCr Alloy wire, i-FeCrAl Alloy wire njll.

Uhlobo lokuvikela ukushisa

| Igama Elifakwe I-Insulation | Izinga LokushisaºC (Isikhathi sokusebenza amahora angama-2000) | Igama Lekhodi | Ikhodi ye-GB | Uhlobo lwe-ANSI |

| Ucingo olune-enamel ye-polyurethane | 130 | I-UEW | QA | MW75C |

| Ucingo olufakwe i-polyester enamel | 155 | I-PEW | QZ | MW5C |

| Ucingo olune-enamel ye-polyester-imide | 180 | I-EIW | QZY | MW30C |

| Intambo ene-enamel eboshwe kabili ene-polyester-imide kanye ne-polyamide-imide | 200 | I-EIWH (DFWF) | QZY/XY | MW35C |

| Ucingo oluhlanganisiwe lwe-polyamide-imide | 220 | I-AIW | I-QXY | MW81C |

Okuqukethwe Kwamakhemikhali, %

| Cu | Bi | Sb | As | Fe | Ni | Pb | S | Zn | Isiqondiso se-ROHS | |||

| Cd | Pb | Hg | Cr | |||||||||

| 99.90 | 0.001 | 0.002 | 0.002 | 0.005 | - | 0.005 | 0.005 | - | ND | ND | ND | ND |

Izakhiwo Ezibonakalayo

| Indawo Yokuncibilika – Liquidus | 1083ºC |

| Indawo Yokuncibilika – iSolidus | 1065ºC |

| Ubuningi | 8.91 gm/cm3@20 ºC |

| Amandla adonsela phansi athile | 8.91 |

| Ukumelana Nogesi | 1.71 microhm-cm @ 20 ºC |

| Ukuqhuba Ugesi** | 0.591 MegaSiemens/cm @ 20 ºC |

| Ukuqhuba Okushisayo | 391.1 W/m · oK ku-20 C |

| Isilinganiso Sokwanda Kokushisa | 16.9 ·10-6 perºC(20-100 ºC) |

| Isilinganiso Sokwanda Kokushisa | 17.3 ·10-6 perºC(20-200 ºC) |

| Isilinganiso Sokwanda Kokushisa | 17.6·10-6 perºC(20-300 ºC) |

| Amandla Okushisa Aqondile | 393.5 J/kg ·oK ku-293 K |

| I-Modulus ye-Elasticity ekucindezelekeni | 117000 Mpa |

| I-Modulus of Rigidity | 44130 Mpa |

Ukusetshenziswa kwe-Copper foil

1) Iziphethu zikagesi kanye nogesi, amaswishi

2) Ozimele be-Lead

3) Izixhumi kanye nezinhlanga zokunyakazisa

3) Insimu ye-PCB

4) Ikhebula lokuxhumana, Ukuvikela ikhebula, Ibhodi elikhulu lefoni ephathekayo

5) I-lamination yokukhiqiza ibhethri le-ion ngefilimu ye-PI

6) Izinto zokuqoqa i-PCB (i-electrode backing)

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu