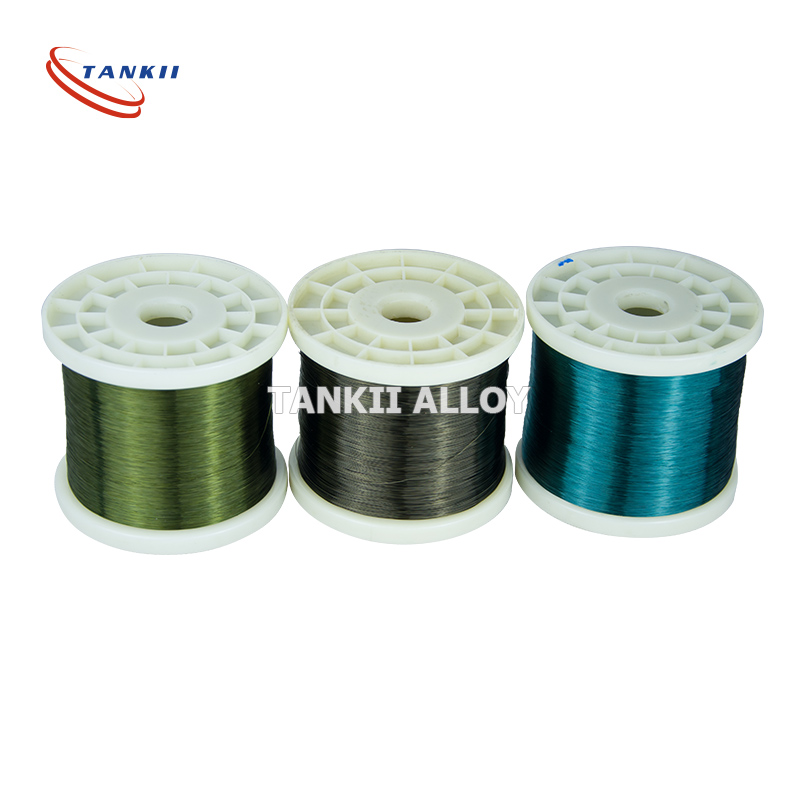

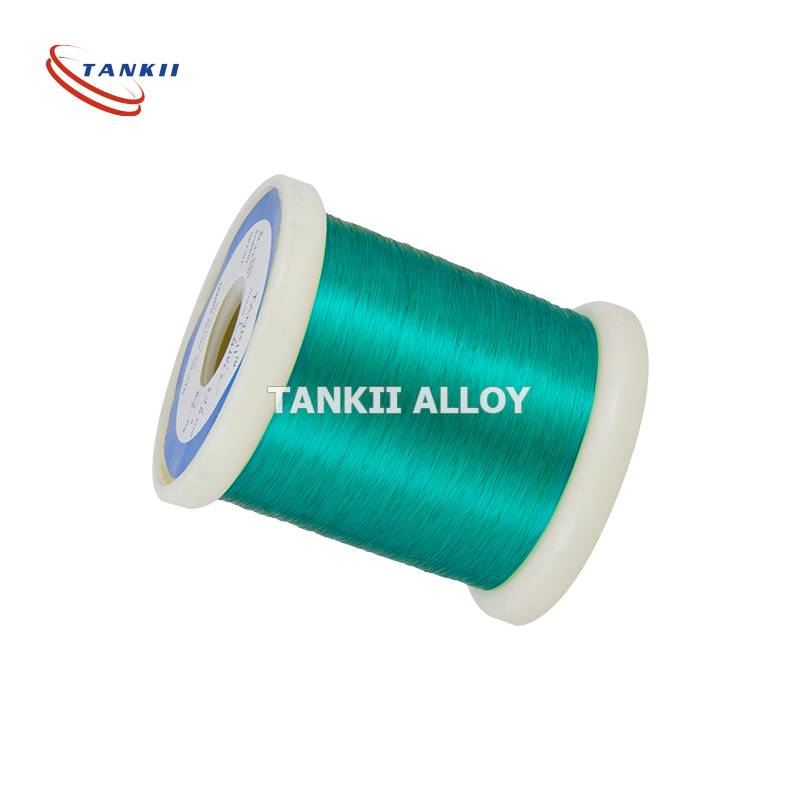

i-copper wire thermal class C / 200*C ANSI UHLOBO MW35C noma i-IEC 317-13. I-Polyester-imide kanye ne-polyamide-imide enameleli yocingo oluphindwe kabili olunamekwe

ucingo lwethusi isigaba se-thermal C/ 200*C ANSI UHLOBO MW35C noma IEC 317-13. I-polyester-imide futhii-polyamide-imidekabili camera enameled Winding wire

Incazelo Yomkhiqizo

Lezi zintambo eziqinile zokumelana zisetshenziswe kabanzi kuma-resistors ajwayelekile, imoto

izingxenye, resistors emazombezombe, njll usebenzisaukwahlukanisaukucutshungulwa okufaneleka kakhulu kulezi zinhlelo zokusebenza, ukusebenzisa ngokugcwele izici ezihlukile zokumbozwa koqweqwe lwawo.

Ngaphezu kwalokho, sizokwenza ukwahlukanisa koqweqwe lwawo koqweqwe lwawo lwezintambo zensimbi eziyigugu njengesiliva neplatinamu uma ku-oda. Sicela usebenzise lokhu kukhiqiza-on-oda.

Uhlobo Lwentambo ye-Nichrome

NiCr80/20,NiCr70/30,NiCr60/15,NiCr90/10,NiCr35/20,NiCr30/20

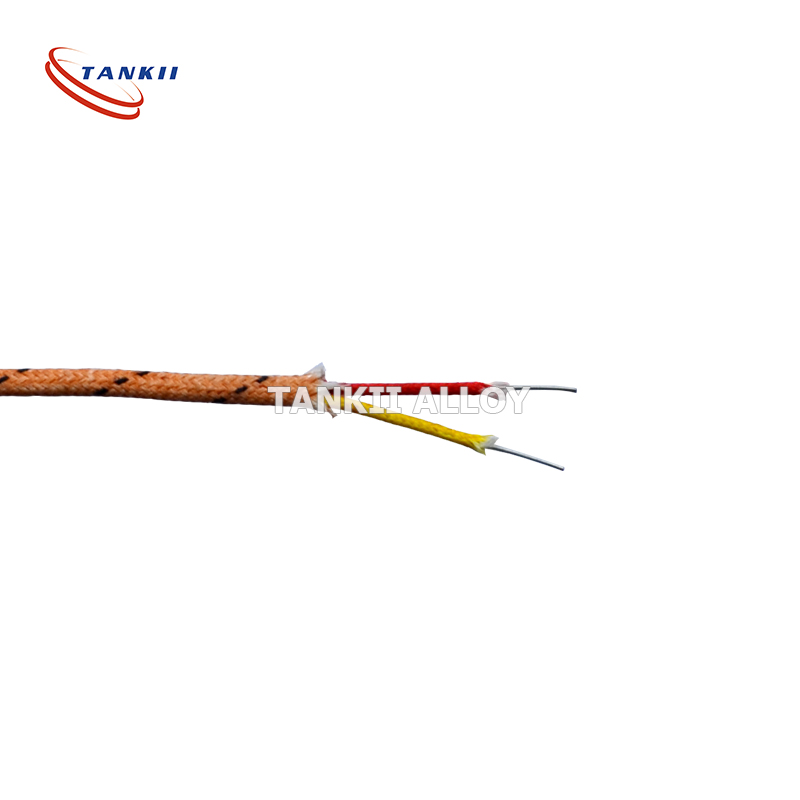

Uhlobo lwe-Insulation

| Igama le-insulation-enamelled | Izinga le-ThermalºC (isikhathi sokusebenza 2000h) | Igama lekhodi | Ikhodi ye-GB | I-ANSI. UHLOBO |

| I-polyurethane enamelled wire | 130 | UEW | QA | MW75C |

| I-polyester enamelled wire | 155 | I-PEW | QZ | MW5C |

| Intambo enamelled ye-polyester-imide | 180 | I-EIW | QZY | MW30C |

| I-Polyester-imide ne-polyamide-imide ehlanganiswe kabili ngocingo olunameleli | 200 | EIWH (DFWF) | QZY/XY | MW35C |

| Intambo enamelled ye-Polyamide-imide | 220 | I-AIW | QXY | MW81C |

Uhlobo Lwe-Bare Alloy Wire

Ingxubevange esingayenza enamelled iCopper-nickel alloy wire,Constantan wire,Manganin wire. I-Kama Wire, i-NiCr Alloy wire, i-FeCrAl Alloy wire njll i-alloy wire

| main impahla uhlobo | Cuni1 | I-CuNI2 | I-CUNI6 | Kunini8 | I-CuNI10 | CuNi14 | Kunini19 | KuNi23 | KuNi30 | CuNi34 | I-CuNI44 | ||

| main amakhemikhali ukwakheka | Ni | 1 | 2 | 6 | 8 | 10 | 14.2 | 19 | 23 | 30 | 34 | 44 | |

| MN | / | / | / | / | / | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | ||

| CU | phumula | phumula | phumula | phumula | phumula | phumula | phumula | phumula | phumula | phumula | phumula | ||

| ubuningi ukusebenza izinga lokushisa | / | 200 | 220 | 250 | 250 | 300 | 300 | 300 | 350 | 350 | 400 | ||

| ukuminyana g/cm3 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | ||

| ukumelana ngo 20 °c | 0.03 ± 10% | 0.05± 10% | 0.10± 10% | 0.12± 10% | 0.15± 10% | 0.20± 5% | 0.25± 5% | 0.30± 5% | 0.35± 5% | 0.40± 5% | 0.49± 5% | ||

| izinga lokushisa i-coefficient ye ukumelana | <100 | <120 | <60 | <57 | <50 | <38 | <25 | <16 | <10 | -0 | <-6 | ||

| ukuqina amandla mpa | > 210 | >220 | >250 | > 270 | > 290 | >310 | > 340 | > 350 | >400 | >400 | > 420 | ||

| ubude | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | ||

| ukuncibilika iphuzu °c | 1085 | 1090 | 1095 | 1097 | 1100 | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | ||

| i-coefficient ye conductivity | 145 | 130 | 92 | 75 | 59 | 48 | 38 | 33 | 27 | 25 | 23 |

I-nicr8020 i-alloy heat wire

1.Mayelana nocingo lwe-Nichrome

I-Nichrome alloy ihlanganisa i-pure nickel, i-NiCr alloy, i-Fe-Cr-Al alloy ne-copper nickel alloy.

Ama-alloys e-nickel chrome: Ni80Cr20, Ni70Cr30, Ni60Cr15, Ni35Cr20, Ni30Cr20, Cr25Ni20, nickel Ni200 neNi201

2.Inzuzo Eyinhloko kanye Nesicelo

1. I-Nickel-chromium, i-nickel-chromium alloy enokumelana okuphezulu nokuzinzile, ukumelana nokugqwala, ukumelana ne-oxidation ebusweni kuhle, okungcono ngaphansi kwezinga lokushisa eliphezulu namandla okuzamazama komhlaba, i-ductility enhle, ukusebenza kahle nokushisela.

2.Imikhiqizo yethu isebenza kakhulu embonini yamakhemikhali, indlela yokwenza insimbi, imboni yengilazi, imboni ye-ceramic, indawo yezinto zikagesi zasendlini nokunye.

3.Ukwakheka kwamakhemikhali:

| Ibhrendi | Ukwakheka kwamakhemikhali | Si | Cr | Ni | Al | Fe | |||

| C | P | S | Mn | ||||||

| Hhayi ngaphezu | |||||||||

| I-Cr20Ni80 | 0.08 | 0.020 | 0.015 | 0.60 | 0.75-1.60 | 20.0-23.0 | hlala | ≤0.50 | ≤1.0 |

| I-Cr15Ni60 | 0.08 | 0.020 | 0.015 | 0.60 | 0.75-1.60 | 15.0-18.0 | 55.0-61.0 | ≤0.50 | hlala |

| I-Cr20Ni35 | 0.08 | 0.020 | 0.015 | 1.00 | 1.00-3.00 | 18.0-21.0 | 34.0-37.0 | - | hlala |

| I-Cr20Ni30 | 0.08 | 0.020 | 0.015 | 1.00 | 1.00-2.00 | 18.0-21.0 | 30.0-34.0 | - | hlala |

Uma umkhiqizo ukusimo “M”, kufanele ulandelwe i-GB/T1234-1995 ejwayelekile

Ukungazweli:

| Ibhrendi | I-Cr20Ni80 | I-Cr20Ni60 | I-Cr20Ni35 | I-Cr20Ni30 | ||

| Ububanzi mm | <0.50 | 0.50-3.0 | <0.50 | ≥0.50 | <0.50 | ≥0.50 |

| ukumelana(20°C)uΩ·m | 1.09±0.05 | 1.13±0.05 | 1.12±0.05 | 1.15±0.05 | 1.04±0.05 | 1.06±0.05 |

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

Whatsapp

-

I-WeChat

Judy

150 0000 2421

-

Phezulu