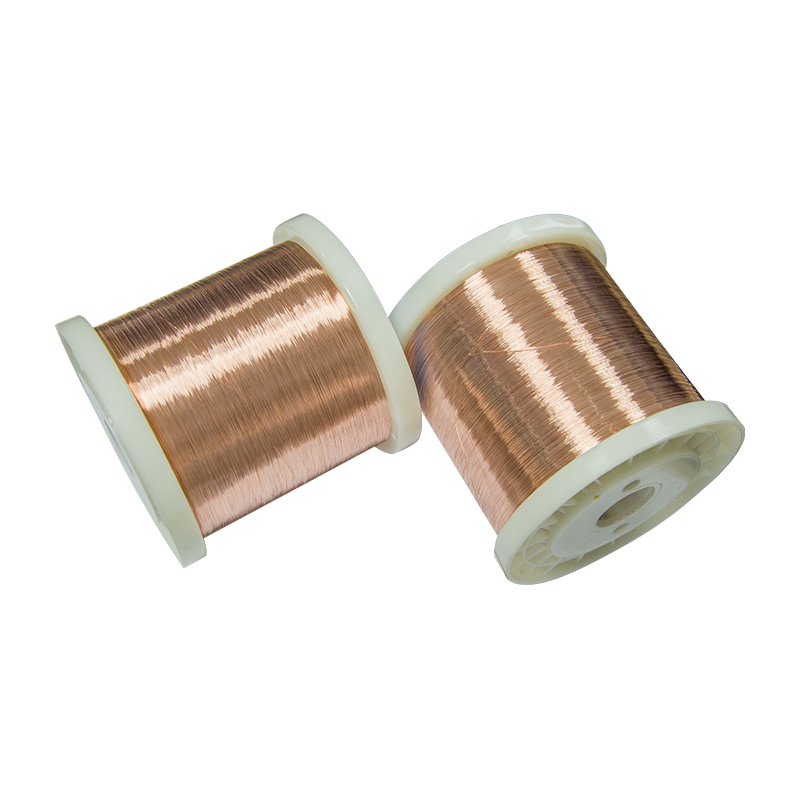

Izintambo ze-Dia 0.6mm Alloy M25 Copper Beryllium zamabhuloho okuxhumana

Incazelo Yomkhiqizo

Ukwakheka Kwamakhemikhali (Amaphesenti Esisindo)I-C17200 Beryllium Copper Alloy:

| Ukuletha Izixazululo | ||||||

| Ingxubevange | I-Beryllium | I-Cobalt | I-Nickel | I-Co + Ni | I-Co+Ni+Fe | Ithusi |

| C17200 | 1.80-2.00 | - | 0.20 Min | 0.20 Min | Ubuningi obungu-0.60 | Ibhalansi |

Isaziso: I-Copper plus engeziwe ilingana no-99.5% Min.

TIzakhiwo Ezivamile Zomzimba ze-C172:

Ubuningi (g/cm3): 8.36

Ubuningi ngaphambi kokuguga (g/cm3): 8.25

I-Elastic Modulus (kg/mm2 (103)): 13.40

I-Coefficient Yokukhulisa Ukushisa (20 °C kuya ku-200 °C m/m/°C): 17 x 10-6

Ukushisa Okuphezulu (cal/(cm-s-°C)): 0.25

Ibanga Lokuncibilika (°C): 870-980

I-Common Temper esiyinikezayo:

| Ukuqokwa kwe-CuBeryllium | I-ASTM | Izakhiwo Zemishini Nezikagesi Ze-Copper Beryllium Strip | ||||||

| Ukuqokwa | Incazelo | Amandla Okudonsa (I-Mpa) | Amandla Okukhiqiza angu-0.2% | Amaphesenti Obude | UBUQINI (HV) | UBUQINI Rockwell Isikali B noma C | Ukuqhuba Kagesi (% IACS) | |

| A | TB00 | Isixazululo Esihlanganisiwe | 410~530 | 190~380 | 35~60 | <130 | 45~78HRB | 15~19 |

| 1/2 H | TD02 | Ukuqina Okungaphelele | 580~690 | 510~660 | 12~30 | 180~220 | 88~96HRB | 15~19 |

| H | TD04 | Kunzima | 680~830 | 620~800 | 2~18 | 220~240 | 96~102HRB | 15~19 |

| HM | TM04 | Ukugaya kuqiniswe | 930~1040 | 750~940 | 9~20 | 270~325 | 28~35HRC | 17~28 |

| I-SHM | TM05 | 1030~1110 | 860~970 | 9~18 | 295~350 | 31~37HRC | 17~28 | |

| I-XHM | TM06 | 1060~1210 | 930~1180 | 4~15 | 300~360 | 32~38HRC | 17~28 | |

Ubuchwepheshe Obuyinhloko Be-Beryllium Copper (Ukwelashwa ngokushisa)

Ukwelashwa ngokushisa kuyinqubo ebaluleke kakhulu yalolu hlelo lwe-alloy. Nakuba zonke i-alloy zethusi ziqina ngokusebenza ngokubandayo, ithusi le-beryllium lihlukile ngokuqina ngokwelashwa okulula kokushisa okuphansi. Kuhilela izinyathelo ezimbili eziyisisekelo. Esokuqala sibizwa ngokuthi i-solution annealing kanti esesibili, ukuqina kwemvula noma ukuguga.

Isixazululo Sokumboza

Kwi-alloy ejwayelekile i-CuBe1.9 (1.8- 2%), i-alloy ishiswa phakathi kuka-720°C no-860°C. Kuleli qophelo, i-beryllium equkethwe empeleni "iyancibilika" ku-matrix yethusi (isigaba se-alpha). Ngokucisha ngokushesha ekushiseni kwegumbi lesi sakhiwo sesisombululo esiqinile siyagcinwa. Izinto ezikulesi sigaba zithambile kakhulu futhi zithambile futhi zingabanda kalula ngokudweba, ukwakha ukugoqa, noma ukubanda. Ukusebenza kwe-annealing yesisombululo kuyingxenye yenqubo emshinini futhi ngokuvamile akusetshenziswa yikhasimende. Izinga lokushisa, isikhathi ekushiseni, izinga lokucima, usayizi wezinhlamvu, kanye nobunzima konke kuyimingcele ebaluleke kakhulu futhi kulawulwa ngokuqinile yi-TANKII.

Ukuqina Kweminyaka

Ukuqina kokuguga kuthuthukisa kakhulu amandla ezinto ezibonakalayo. Lokhu kusabela ngokuvamile kwenziwa emazingeni okushisa aphakathi kuka-260°C no-540°C kuye ngokuthi i-alloy kanye nezici ezifunwayo. Lo mjikelezo ubangela ukuthi i-beryllium encibilikisiwe ifinyelele njengesigaba esicebile se-beryllium (gamma) ku-matrix nasemingceleni yokusanhlamvu. Ukwakheka kwalokhu kufinyelela okubangela ukwanda okukhulu kwamandla ezinto ezibonakalayo. Izinga lezakhiwo zemishini ezifinyelelwayo linqunywa izinga lokushisa nesikhathi ekushiseni. Kufanele kuqashelwe ukuthi ithusi le-beryllium alinazo izici zokuguga ekushiseni kwegumbi.

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu