I-PTFE Insulation Material N Thermocouple Alloy Ehlala Eqinile

Imininingwane

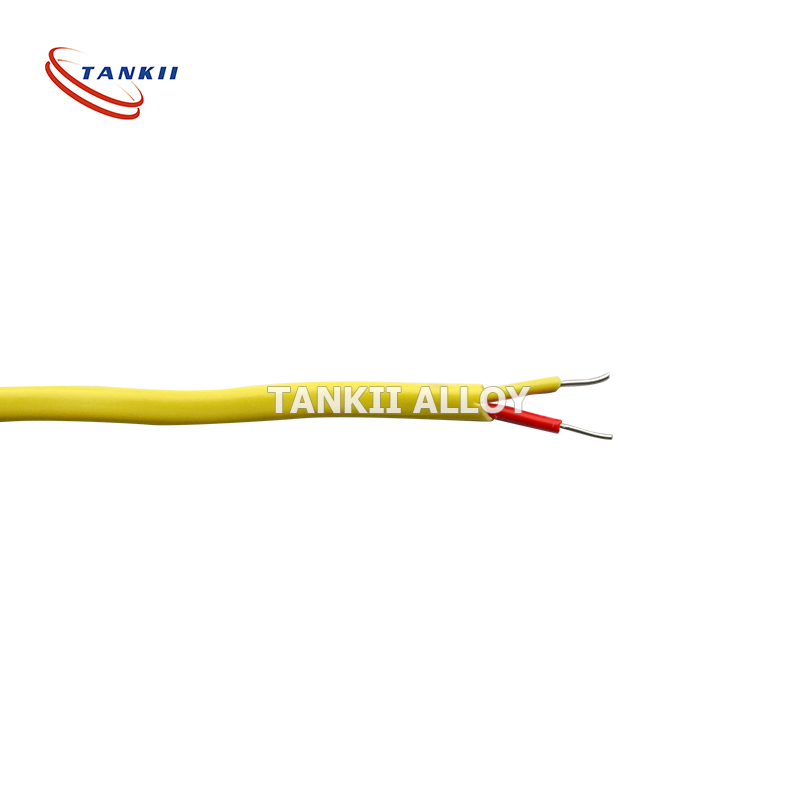

1.Isitayela:Intambo Yokunweba

2.Thermocoupleucingo lwethusi

I-Thermocouple copper wire Classification

1. Izinga le-Thermocouple (izinga lokushisa eliphezulu). Lolu hlobo locingo lwe-thermocouple lufaneleka kakhulu uhlobo lwe-thermocouple K, J, E, T, N no-L kanye nezinye izinsimbi zokuthola izinga lokushisa eliphezulu, inzwa yokushisa, njll.

2. Ukunxephezela izinga lezintambo (izinga lokushisa eliphansi). Lolu hlobo lwentambo ye-thermocouple lufaneleka kakhulu ukunxephezela ikhebula nocingo lokunwetshwa kwama-thermocouples ahlukahlukene ohlobo lwe-S, R, B, K, E, J, T, N no-L, ikhebula lokushisa, ikhebula lokulawula njalonjalo.

Izinhlobonhlobo ze-thermocouple kanye nenkomba

| I-Thermocouple Variety kanye ne-Index | ||

| Izinhlobonhlobo | Uhlobo | Ibanga Lokulinganisa(°C) |

| I-NiCr-NiSi | K | -200-1300 |

| I-NiCr-CuNi | E | -200-900 |

| Fe-CuNi | J | -40-750 |

| Ku-CuNi | T | -200-350 |

| I-NiCrSi-NiSi | N | -200-1300 |

| I-NiCr-AuFe0.07 | I-NiCr-AuFe0.07 | -270-0 |

Ubukhulu nokubekezelela kwe-Fiberglass Insulated Thermocouple Wire

Ubukhulu / Ukubekezelela mm ) : 4.0+-0.25

Ikhodi yombala nokubekezelelwa kokuqala kokulinganisa kwentambo ye-thermocouple:

| Uhlobo lwe-Thermocouple | Ikhodi Yombala ye-ANSI | Ukubekezelelwa Kokulinganisa Kokuqala | ||||

| Ama-Wire Alloys | Ukulinganisa | +/- Umqhubi | Ijakhethi | Izinga Lokushisa | Okujwayelekile Imikhawulo | Okukhethekile Imikhawulo |

| Insimbi(+) vs. I-Constantan(-) | J | Emhlophe/Bomvu | Brown | 0°C kuya +285°C 285°C kuya +750°C | ±2.2°C ± .75% | ±1.1°C ± .4% |

| CHROMEL(+) vs. I-ALUMEL(-) | K | Ophuzi/Obomvu | Brown | -200°C kuya ku-110°C -110°C kuya ku-0°C 0°C kuya +285°C 285°C kuya +1250°C | ± 2% ±2.2°C ±2.2°C ± .75% | ±1.1°C ± .4% |

| Ithusi(+) vs. I-Constantan(-) | T | Okuluhlaza/Okubomvu | Brown | -200°C kuya ku-65°C -65°C kuya +130°C 130°C kuya +350°C | ± 1.5% ±1°C ± .75% | ± .8% ± .5°C ± .4% |

| CHROMEL(+) vs. I-Constantan(-) | E | Okunsomi/Obomvu | Brown | -200°C kuya ku-170°C -170°C kuya +250°C 250°C kuya +340°C 340°C+900°C | ± 1% ±1.7°C ±1.7°C ± .5% | ±1°C ±1°C ± .4% ± .4% |

Ikhodi Yombala kanye Nokubekezelela Kokulinganisa Kokuqala Kwentambo Yokunweba:

| Uhlobo lwesandiso | Ikhodi Yombala ye-ANSI | Ukubekezelelwa Kokulinganisa Kokuqala | ||||

| Ama-Wire Alloys | Ukulinganisa | +/- Umqhubi | Ijakhethi | Izinga Lokushisa | Okujwayelekile Imikhawulo | Okukhethekile Imikhawulo |

| Insimbi (+) vs. Constantan(-) | JX | Emhlophe/Bomvu | Emnyama | 0°C kuya +200°C | ±2.2°C | ±1.1°C |

| I-CHROMEL (+) iqhudelana ne-ALUMEL (-) | KX | Ophuzi/Obomvu | Okuphuzi | 0°C kuya +200°C | ±2.2°C | ±1.1°C |

| Ithusi(+) vs. Constantan(-) | TX | Okuluhlaza/Okubomvu | Okuluhlaza okwesibhakabhaka | -60°C kuya +100°C | ±1.1°C | ± .5°C |

| I-CHROMEL(+) vs. Constantan(-) | EX | Okunsomi/Obomvu | Okunsomi | 0°C kuya +200°C | ±1.7°C | ±1.1°C |

Izinto ezibonakalayo ze-PVC-PVC:

| Izici | I-Insulation | Ijakhethi |

| Ukumelana ne-Abrasion | Kuhle | Kuhle |

| Nciphisa Ukumelana | Kuhle | Kuhle |

| Ukumelana Nomswakama | Kuhle kakhulu | Kuhle kakhulu |

| I-Solder Iron Resistance | Impofu | Impofu |

| Izinga Lokushisa Lesevisi | 105ºC okuqhubekayo 150ºC eyodwa | 105ºC okuqhubekayo 150ºC eyodwa |

| Flame Test | Ukuzicisha | Ukuzicisha |

Iphrofayela Yenkampani

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

Whatsapp

-

I-WeChat

Judy

150 0000 2421

-

Phezulu