I-Nichrome Enameled / Constantan / Copper / Lizt / Color Wire / Silver / Twist Wire

Incazelo Yomkhiqizo

Lezi zintambo eziqinile zokumelana zisetshenziswe kabanzi kuma-resistors ajwayelekile, imoto

izingxenye, izinqamuleli ezimazombezombe, njll. kusetshenziswa ukucutshungulwa kwe-insulation ezifaneleka kakhulu lezi zinhlelo zokusebenza, zisebenzisa ngokugcwele izici ezihlukile zokumbozwa koqweqwe lwawo.

Ngaphezu kwalokho, sizokwenza ukwahlukanisa koqweqwe lwawo koqweqwe lwawo lwezintambo zensimbi eziyigugu njengesiliva neplatinamu uma ku-oda. Sicela usebenzise lokhu kukhiqiza-on-oda.

Uhlobo Lwentambo ye-Nichrome

NiCr80/20,NiCr70/30,NiCr60/15,NiCr90/10,NiCr35/20,NiCr30/20

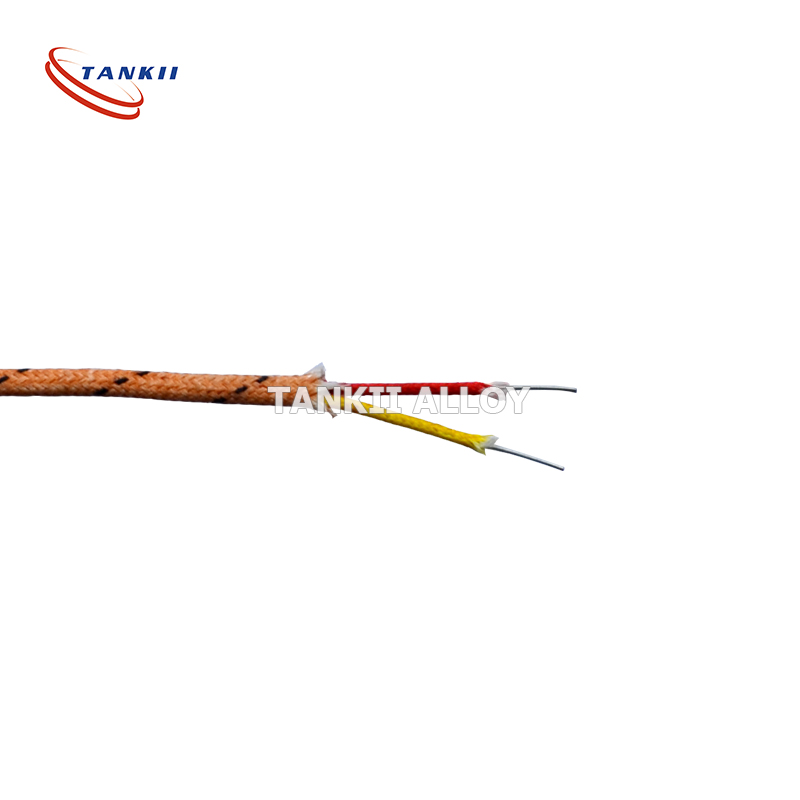

Uhlobo lwe-Insulation

| Igama le-insulation-enamelled | Izinga le-ThermalºC (isikhathi sokusebenza 2000h) | Igama lekhodi | Ikhodi ye-GB | I-ANSI. UHLOBO |

| I-polyurethane enamelled wire | 130 | UEW | QA | MW75C |

| I-polyester enamelled wire | 155 | I-PEW | QZ | MW5C |

| Intambo enamelled ye-polyester-imide | 180 | I-EIW | QZY | MW30C |

| I-polyester-imide ne-polyamide-imide ehlanganiswe kabiliucingo olungenantambo | 200 | EIWH (DFWF) | QZY/XY | MW35C |

| Intambo enamelled ye-Polyamide-imide | 220 | I-AIW | QXY | MW81C |

Uhlobo Lwe-Bare Alloy Wire

Ingxubevange esingayenza enamelled iCopper-nickel alloy wire,Constantan wire,Manganin wire. I-Kama Wire, i-NiCr Alloy wire, i-FeCrAl Alloy wire njll i-alloy wire

| main impahla uhlobo | Cuni1 | I-CuNI2 | I-CUNI6 | Kunini8 | I-CuNI10 | Kunini19 | KuNi23 | KuNi30 | CuNi34 | I-CuNI44 | |

| main amakhemikhali ukwakheka | Ni | 1 | 2 | 6 | 8 | 10 | 19 | 23 | 30 | 34 | 44 |

| MN | / | / | / | / | / | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| CU | phumula | phumula | phumula | phumula | phumula | phumula | phumula | phumula | phumula | phumula | |

| ubuningi ukusebenza izinga lokushisa | / | 200 | 220 | 250 | 250 | 300 | 300 | 350 | 350 | 400 | |

| ukuminyana g/cm3 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| ukumelana ngo 20 °c | 0.03 ± 10% | 0.05± 10% | 0.10± 10% | 0.12± 10% | 0.15± 10% | 0.25± 5% | 0.30± 5% | 0.35± 5% | 0.40± 5% | 0.49± 5% | |

| izinga lokushisa i-coefficient ye ukumelana | <100 | <120 | <60 | <57 | <50 | <25 | <16 | <10 | -0 | <-6 | |

| ukuqina amandla mpa | > 210 | >220 | > 250 | > 270 | > 290 | > 340 | > 350 | >400 | >400 | > 420 | |

| ubude | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | |

| ukuncibilika iphuzu °c | 1085 | 1090 | 1095 | 1097 | 1100 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| i-coefficient ye conductivity | 145 | 130 | 92 | 75 | 59 | 38 | 33 | 27 | 25 | 23 |

I-nicr8020 i-alloy heat wire

1.Mayelana nocingo lwe-Nichrome

I-Nichrome alloy ihlanganisa i-pure nickel, i-NiCr alloy, i-Fe-Cr-Al alloy ne-copper nickel alloy.

Ama-alloys e-nickel chrome: Ni80Cr20, Ni70Cr30, Ni60Cr15, Ni35Cr20, Ni30Cr20, Cr25Ni20, nickel Ni200 neNi201

2.Inzuzo Eyinhloko kanye Nesicelo

1. I-Nickel-chromium, i-nickel-chromium alloy enokumelana okuphezulu nokuzinzile, ukumelana nokugqwala, ukumelana ne-oxidation ebusweni kuhle, okungcono ngaphansi kwezinga lokushisa eliphezulu namandla okuzamazama komhlaba, i-ductility enhle, ukusebenza kahle nokushisela.

2.Imikhiqizo yethu isebenza kakhulu embonini yamakhemikhali, indlela yokwenza insimbi, imboni yengilazi, imboni ye-ceramic, indawo yezinto zikagesi zasendlini nokunye.

1) Ukwakheka kwamakhemikhali:

| Ibhrendi | Ukwakheka kwamakhemikhali | Si | Cr | Ni | Al | Fe | |||

| C | P | S | Mn | ||||||

| Hhayi ngaphezu | |||||||||

| I-Cr20Ni80 | 0.08 | 0.020 | 0.015 | 0.60 | 0.75-1.60 | 20.0-23.0 | hlala | ≤0.50 | ≤1.0 |

| I-Cr15Ni60 | 0.08 | 0.020 | 0.015 | 0.60 | 0.75-1.60 | 15.0-18.0 | 55.0-61.0 | ≤0.50 | hlala |

| I-Cr20Ni35 | 0.08 | 0.020 | 0.015 | 1.00 | 1.00-3.00 | 18.0-21.0 | 34.0-37.0 | - | hlala |

| I-Cr20Ni30 | 0.08 | 0.020 | 0.015 | 1.00 | 1.00-2.00 | 18.0-21.0 | 30.0-34.0 | - | hlala |

2) Ubukhulu nokubekezelelana

Uma umkhiqizo ukusimo “M”, kufanele ulandelwe i-GB/T1234-1995 ejwayelekile

1) Ukumelana:

| Ibhrendi | I-Cr20Ni80 | I-Cr20Ni60 | I-Cr20Ni35 | I-Cr20Ni30 | ||

| Ububanzi mm | <0.50 | 0.50-3.0 | <0.50 | ≥0.50 | <0.50 | ≥0.50 |

| ukumelana(20°C)uΩ·m | 1.09±0.05 | 1.13±0.05 | 1.12±0.05 | 1.15±0.05 | 1.04±0.05 | 1.06±0.05 |

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

Whatsapp

-

I-WeChat

Judy

150 0000 2421

-

Phezulu