Ucingo olufakwe enamel Intambo ye-Ni80Cr20 NiCr8020 enokusebenza okuhle kokuvikela

Incazelo Yomkhiqizo

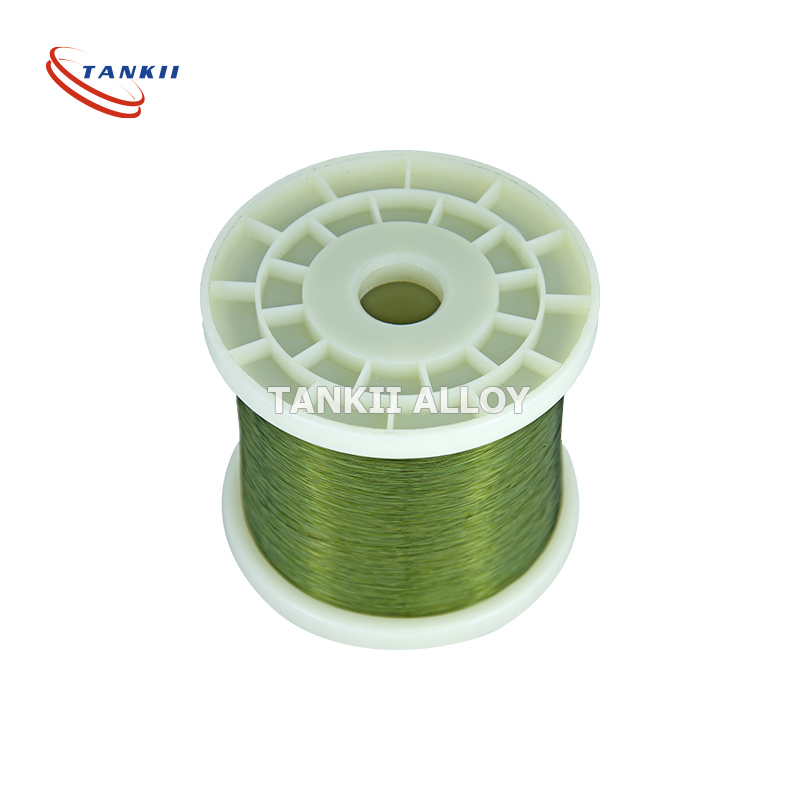

I-Karma Enameled Wire Dia 0.08mm Resistance Heating Wire ye-Precision Instrument

Incazelo Yomkhiqizo

Lezi zintambo zokumelana ezihlanganisiwe zisetshenziswe kabanzi kuma-resistor ajwayelekile, izimoto

izingxenye, ama-winding resistors, njll. kusetshenziswa ukucubungula kokushisa okulungele kakhulu lezi zinhlelo zokusebenza, kusetshenziswa ngokugcwele izici ezihlukile zokugqoka kwe-enamel.

Ngaphezu kwalokho, sizokwenza ukuvikela uqweqwe lwe-enamel ngentambo yensimbi eyigugu njengesiliva nentambo yeplatinum uma u-oda. Sicela usebenzise lokhu kukhiqiza ngoku-oda.

Impahla yeKarma

| igama | ikhodi | Ukwakheka Okuyinhloko (%) | Okujwayelekile

| |||

| Cr | Al | Fe | Ni | |||

| I-Karma | 6J22 | 19~21 | 2.5~3.2 | 2.0~3.0 | ibhalansi. | I-JB/T 5328 |

| Igama | Ikhodi | (20ºC) Ukumelana i-vity | (20ºC) I-Coeff Yezinga Lokushisa. Ukumelana | (0~100ºC) Ukushisa I-EMF vs. Ithusi | Ukusebenza Okukhulu g | (%) I-Elongati on | (N/mm2) Ukuthamba Amandla | Okujwayelekile |

| I-Karma | 6J22 | 1.33±0.07 | ≤±20 | ≤2.5 | ≤300 | >7 | ≥780 | I-JB/T 5328 |

4. Izici ezihlukile zocingo lokumelana neKarma

1) Siqala nge-Nickel Chromium kagesi we-heat wire Class 1, sishintshe ezinye ze-Ni nge

I-Al nezinye izakhi, ngaleyo ndlela yathola ukumelana okunembile ngezinto ezithuthukisiwe

i-coefficient yokumelana nokushisa kanye namandla okushisa e-electromotive ngokumelene nethusi.

Ngokungezwa kwe-Al, siphumelele ekwenzeni ukumelana kwevolumu kube kukhulu ngokuphindwe ka-1.2

kune-Nickel Chromium kagesi i-heat wire Class 1 kanye namandla okunamathela amakhulu ngokuphindwe ka-1.3.

2) I-coefficient yesibili yokushisa β ye-Karmalloy wire KMW incane kakhulu, - 0.03 × 10-6/ K2,

futhi ijika lokushisa lokumelana liphenduka cishe libe umugqa oqondile ngaphakathi kobubanzi

ububanzi bokushisa.

Ngakho-ke, i-coefficient yokushisa isethwe ukuthi ibe yi-coefficient yokushisa ephakathi

23 ~ 53 °C, kodwa 1 × 10-6/K, isilinganiso sokushisa esiphakathi kuka-0 ~ 100 °C, singase futhi

kufanele yamukelwe ngokwesilinganiso sokushisa.

3) Amandla e-electromotive ngokumelene nethusi eliphakathi kuka-1 ~ 100 °C nawo mancane, ngaphansi kuka-+ 2 μV/K, futhi

ikhombisa ukuzinza okuhle kakhulu esikhathini seminyaka eminingi.

4) Uma lokhu kuzosetshenziswa njengento yokumelana nokunemba, ukwelashwa kokushisa okuphansi kuyasebenza

kudingeka ukuze kuqedwe ukuphazamiseka kokucubungula njengoba kunjalo nge-Manganin wire CMW.

Uhlobo Lokumboza

| Igama Elifakwe I-Insulation | Izinga LokushisaºC (Isikhathi sokusebenza amahora angama-2000) | Igama Lekhodi | Ikhodi ye-GB | Uhlobo lwe-ANSI |

| Ucingo olune-enamel ye-polyurethane | 130 | I-UEW | QA | MW75C |

| Ucingo olufakwe i-polyester enamel | 155 | I-PEW | QZ | MW5C |

| Ucingo olune-enamel ye-polyester-imide | 180 | I-EIW | QZY | MW30C |

| I-polyester-imide kanye ne-polyamide-imide embozwe kabiliucingo olune-enamel | 200 | I-EIWH (DFWF) | QZY/XY | MW35C |

| Ucingo oluhlanganisiwe lwe-polyamide-imide | 220 | I-AIW | I-QXY | MW81C |

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu