Siyakwamukela kumawebhusayithi ethu!

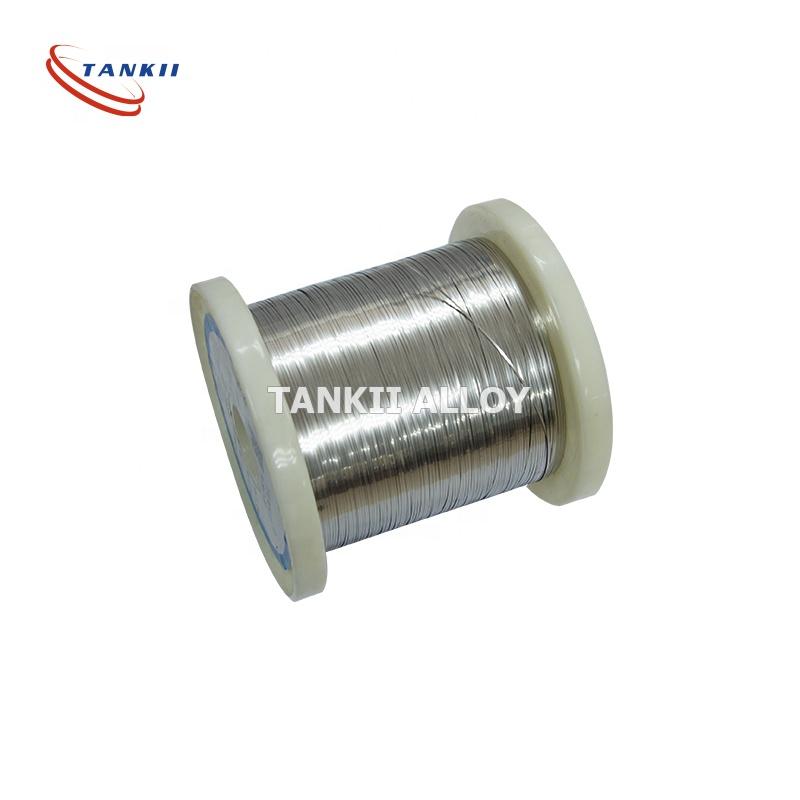

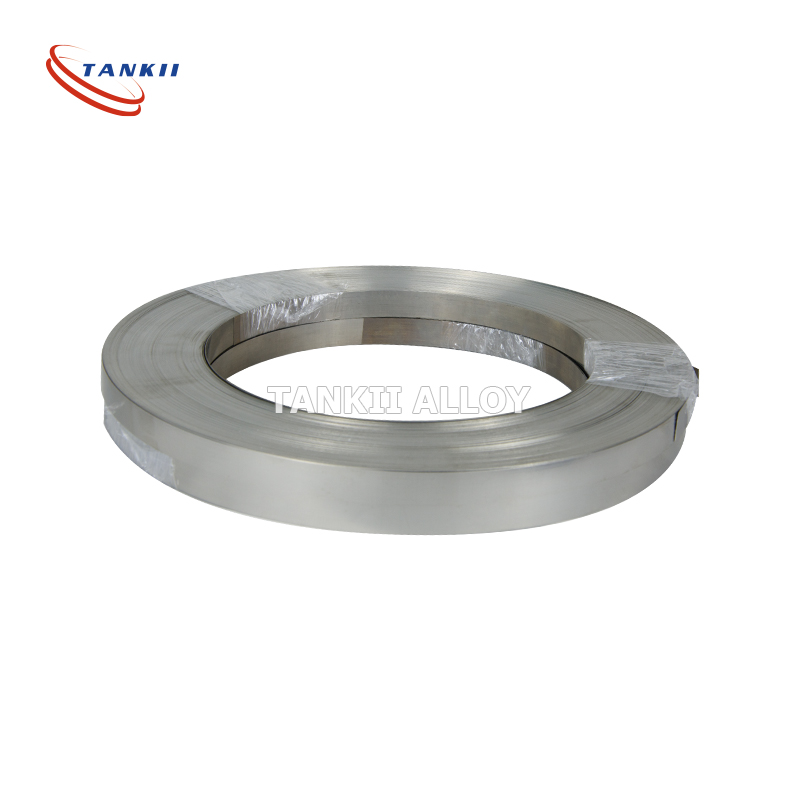

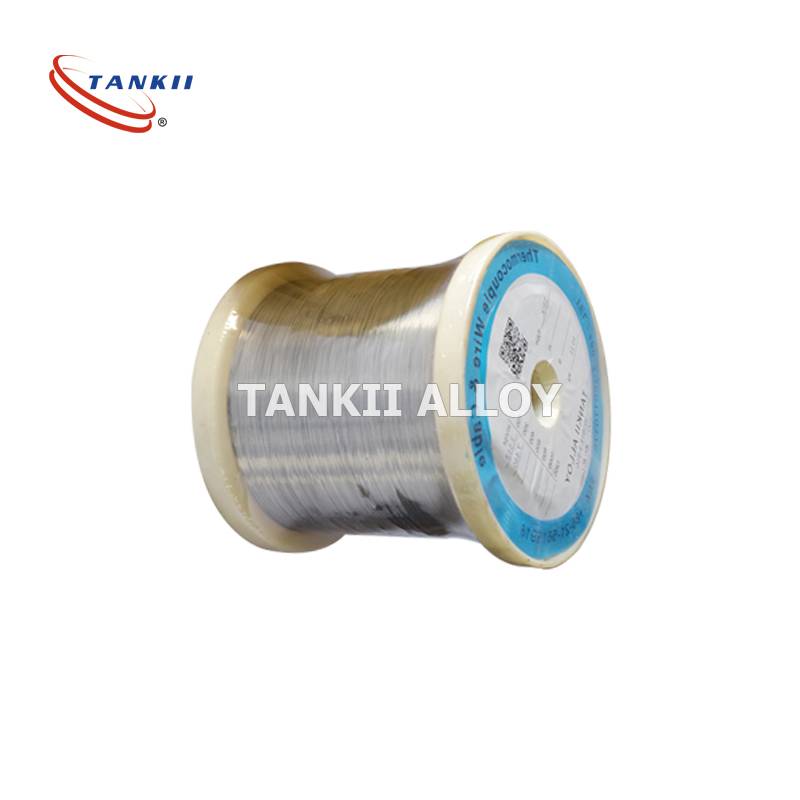

I-FeCrAl 0cr23al5 insimbi eyisicaba kanye nentambo yokushisa eyenziwe efektri

I-FeCrAl 0cr23al5 insimbi yokushisa eyisicaba kanye nentamboumugqangefektri

| Ibanga | 0Cr23Al5 |

| Usayizi | ukujiya: 0.05-3mm ububanzi: 4-250mm |

| Ubuso | ukuqhekeka okukhanyayo |

| Isisindo | 1-3kg/roll, ngokwenani lamakhasimende |

| Ukumelana | 1.3±0.05μΩ.m |

| Ubulukhuni (HV) | 180-210HV |

| Ukwelulwa | ≥16% |

| Ibanga | Izinga lokushisa eliphakeme kakhulu | Ukumelana | Ubulukhuni | Amandla okudonsa | Ukwelulwa |

| 0Cr13Al4 | 1050℃ | 1.25±0.05μΩ.m | 180-210HV | ≥550N/mm2 | ≥16 |

| 0Cr15Al5 | 1100℃ | 1.3±0.05μΩ.m | 180-210HV | ≥550N/mm2 | ≥16 |

| 0Cr21Al6Nb | 1300℃ | 1.42±0.05μΩ.m | 200-240HV | 750N/mm2 | ≥12 |

| I-Cr20Ni80 | 1200℃ | 1.09±0.05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| I-Cr15Ni60 | 1150℃ | 1.12±0.05μΩ.m | 175-210HV | 750N/mm2 | ≥20 |

| I-Cr20Ni35 | 1100℃ | 1.04±0.05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| I-Cr25Ni20(310S) | 1100℃ | 0.86±0.05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| Ibanga | Ukwakheka kwamakhemikhali% | ||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | |

| ≤ | |||||||||

| 0Cr15Al5 | 0.04 | 0.02 | 0.01 | 0.3 | ≤0.5 | 13-14 | 1 | 4.8-5.0 | ibhalansi |

| 0Cr21Al6Nb | 0.05 | 0.025 | 0.02 | 0.5 | ≤0.6 | 21-23 | ≤0.6 | 5-7 | ibhalansi |

| 0Cr13Al4 | 0.04 | 0.02 | 0.01 | 0.3 | ≤0.5 | 13-14 | 1 | 4.8-5.0 | ibhalansi |

| I-Cr20Ni80 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.6 | 20-23 | ibhalansi | <0.5 | ≤1.0 |

| I-Cr15Ni60 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.6 | 15-18 | 55-61 | <0.5 | ibhalansi |

| I-Cr20Ni35 | 0.08 | 0.02 | 0.015 | 1.0 | 1-3 | 18-21 | 34-37 | - | ibhalansi |

| I-Cr25Ni20 | 0.08 | 0.045 | 0.03 | 2.0 | 0.4-0.6 | 24-26 | 19-22 | - | ibhalansi |

I-Shanghai Tankii ALLOY Material Co., Ltd. igxile ekukhiqizweni kwe-nichrome alloy, i-thermocouple wire, i-fecral alloy, i-precision alloy, i-copper nickel alloy, i-thermal spray alloy njll. ngesimo se-wire, ishidi, i-tape,umugqa,induku nepuleti.

Sesivele sinesitifiketi sesistimu yekhwalithi ye-ISO 9001 kanye nokuvunyelwa kohlelo lokuvikela imvelo lwe-ISO 14001. Sineqoqo eliphelele lokugeleza kokukhiqiza okuthuthukisiwe kokucwenga, ukunciphisa ukubanda, ukudweba kanye nokwelapha ukushisa njll. Siphinde sibe namandla ocwaningo nokuthuthukiswa azimele.

Bhala umlayezo wakho lapha bese uwuthumela kithi

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu