Intambo Yokumelana Nokushisa Ephakeme Ye-Fecral Ferro-Chromium-Aluminium D A1 Tk1 Apm

I-FecralI-Ferro-Chromium-AluminiumIntambo Yokumelana Nokushisa Ephakeme Ka-D A1 Tk1 Apm

I-TK-APMI-Ferro-Chromium-I-Aluminiyamu Ingxubevange

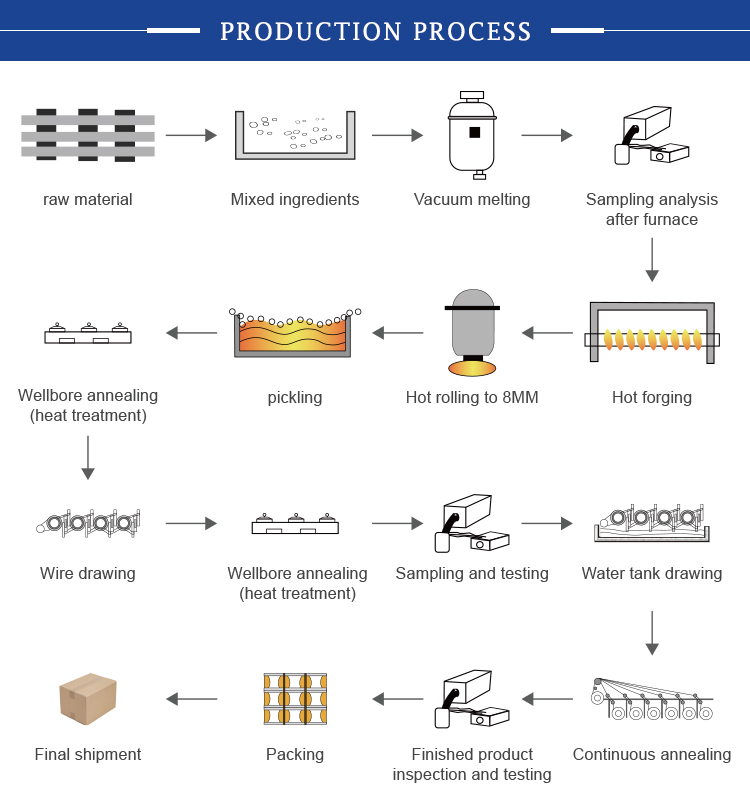

Lo mkhiqizo uthatha i-master alloy ecwengisisiwe njengezinto zokusetshenziswa, ukusetshenziswa kwayoi-powder metallurgyubuchwepheshe bokukhiqiza ama-ingot e-alloy, futhi akhiqizwa ngenqubo ekhethekile yokucubungula okubandayo nokushisa kanye nokwelashwa kokushisa. Lo mkhiqizo unezinzuzo zokumelana okunamandla kwe-oxidation, ukumelana okuhle kokugqwala ekushiseni okuphezulu, ukukhukhuleka okuncane kwezingxenye ze-electrothermal, impilo ende yesevisi ekushiseni okuphezulu kanye nokushintsha okuncane kokumelana. Ufanelekela izinga lokushisa eliphezulu elingu-1420 C, ukuminyana kwamandla aphezulu, umoya oqothulayo, umoya wekhabhoni kanye nezinye izindawo zokusebenza. Ungasetshenziswa kuma-oven e-ceramic, kuma-oven e-oven e-oven e-oven e-oven e-oven, kuma-oven e-laboratory, kuma-oven e-electronic ezimboni kanye nama-oven e-diffusion.

ukwakheka okuyinhloko

| C | Si | Mn | Cr | Al | Fe | |

| Ubuncane | - | - | - | 20 | 5.5 | Ibhalansi. |

| Ubuningi | 0.04 | 0.5 | 0.4 | 22 | 6.0 | Ibhalansi. |

Izakhiwo eziyinhloko zemishini

Amandla Okudonsa Ekamelweni Lokushisa: 650-750MPa

Izinga lobude: 15-25%

ubulukhuni: HV220-260

Amandla Okuqina angu-1000ºC ku-1000ºC Izinga Lokushisa 22-27MPa

1000ºC6MPa Ukuqina Kwezinga Lokushisa Eliphezulu ku-1000 Izinga Lokushisa kanye ne-6MPa ≥100h

Izakhiwo eziyinhloko zomzimba

ukuminyana 7.1g/cm3

ukumelana 1.45×10-6 Ω.m

I-Coefficient Yokushisa Yokumelana (Ct)

iphuzu lokuncibilika: 1500ºC

Izinga Lokushisa Eliphezulu Lokusebenza Eliqhubekayo 1400ºC

| 800ºC | 1000ºC | 1400ºC |

| 1.03 | 1.04 | 1.05 |

Isilinganiso se-coefficient yokwandisa okuqondile ()

| 20-800ºC | 20-1000ºC | 20-1400ºC |

| 14 | 15 | 16 |

Impilo esheshayo

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu