Intambo Yokushisa Ephakeme Kakhulu Ye-Fecral Resistohm145 A1 Tk1 Kan A1 Apm

Imininingwane eyinhloko kanye nokusetshenziswa:

Imininingwane Yomkhiqizo Ojwayelekile: 0.5 ~ 10 mm

Ukusetshenziswa: Kusetshenziswa kakhulu ku-powder metallurgy furnace, ku-diffusion furnace, ku-radiant tube heater kanye nazo zonke izinhlobo zokushisa komzimba ku-furnace ephezulu.

Imaniwali yosebenzisayo

1. I-Voltage Elinganisiwe: 220V/380V

2. Inqubo yokufaka ukuze bagweme ukungqongqoza, ukuze bagweme ucingo lwesitofu olumanzi nolubanjwa ngesandla, kufanele bagqoke amagilavu. Ucingo kufanele lufakwe ngemva kokuba isithando somlilo sihlale sithe tyaba, futhi luvimbele ukuklwebheka kobuso, ukungcola, ukugqwala, noma ukufakwa okungafanele, ngokuthinta impilo yesikhathi

3. Ku-voltage elinganisiwe okufanele isetshenziswe. Emoyeni onciphayo kakhulu, emoyeni one-asidi, umoya womswakama ophezulu uzothinta ukusetshenziswa kokuphila;

4. Izinga lokushisa ngaphambi kokusebenzisa kufanele libe semoyeni owomile ongagqwali, cishe u-1000ºC uchithe amahora ambalwa, ukuze ifilimu yokuvikela ucingo lwesithando ivele ebusweni ngemva kokusetshenziswa okuvamile, ukuze kuqinisekiswe impilo evamile yocingo lwesithando;

5. Ukufakwa kwesithando kufanele kuqinisekise ukuthi intambo evalekile inamandla amakhulu okugwema ukuthinta isithando ngemva kwentambo, ukuvikela ukushaqeka kukagesi noma ukusha.

Uma kukhona umbuzo, sicela ukhululeke ukusitshela.

| Izakhiwo \ Ibanga | 145A1 | |||

| Cr | Al | Re | Fe | |

| 25.0 | 6.0 | Kuyafaneleka | Ibhalansi | |

| Izinga Lokushisa Eliphezulu Lesevisi Eqhubekayo (º C) | Dubukhulu obungu-1.0-3.0 | Ububanzi> 3.0, | ||

| 1225-1350º C | 1400º C | |||

| Ukuqina kokuqina 20º C (Ω mm2/m) | 1.45 | |||

| Ubuningi (g/cm3) | 7.1 | |||

| Isilinganiso Sokuncibilika (º C) | 1500 | |||

| Ukwelulwa (%) | 16-33 | |||

| Imvamisa Yokugoba Ngokuphindaphindwayo (F/R) 20º C | 7-12 | |||

| Impilo esheshayo/h | > 80/1350 | |||

| Isakhiwo se-Micrographic | I-Ferrite | |||

Izigaba zemikhiqizo

-

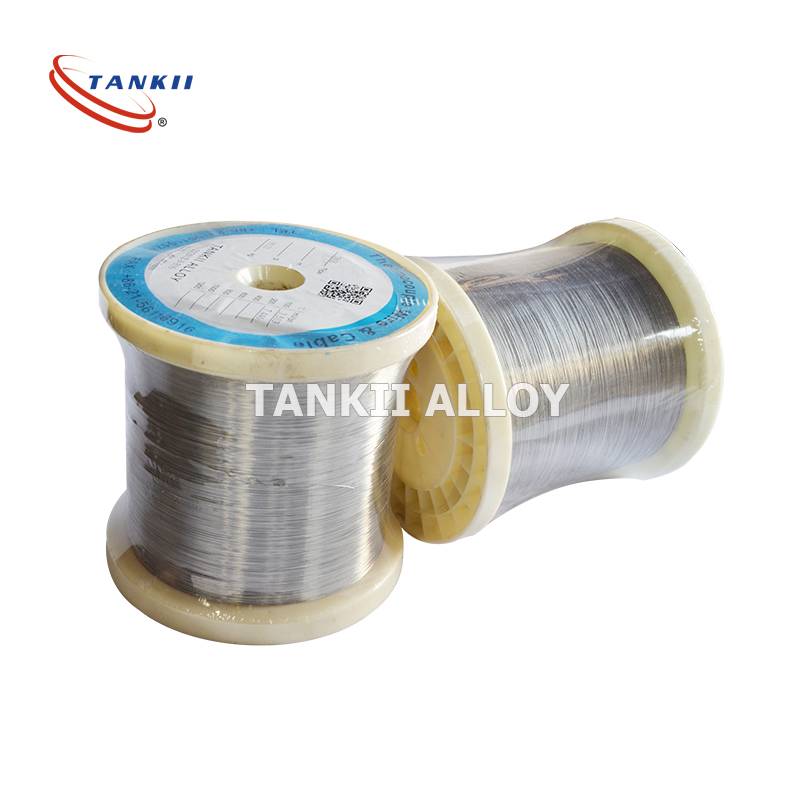

Ucingo

-

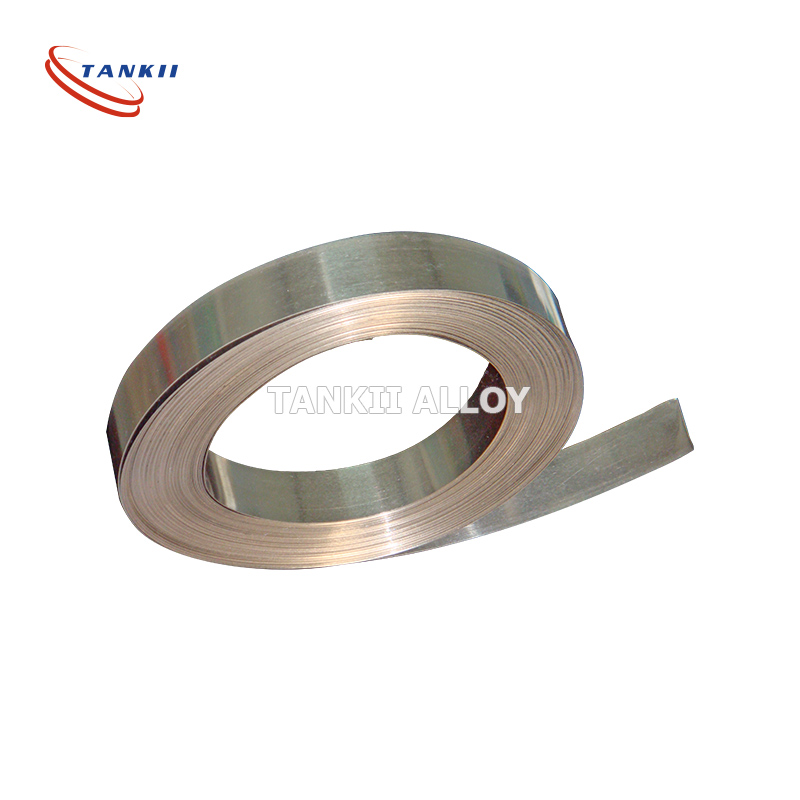

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu