Siyakwamukela kumawebhusayithi ethu!

I-High Stability 6J11 New Constantan Alloy Strip Efanelekela Ukukhiqiza Ithuluzi Lokucacisa

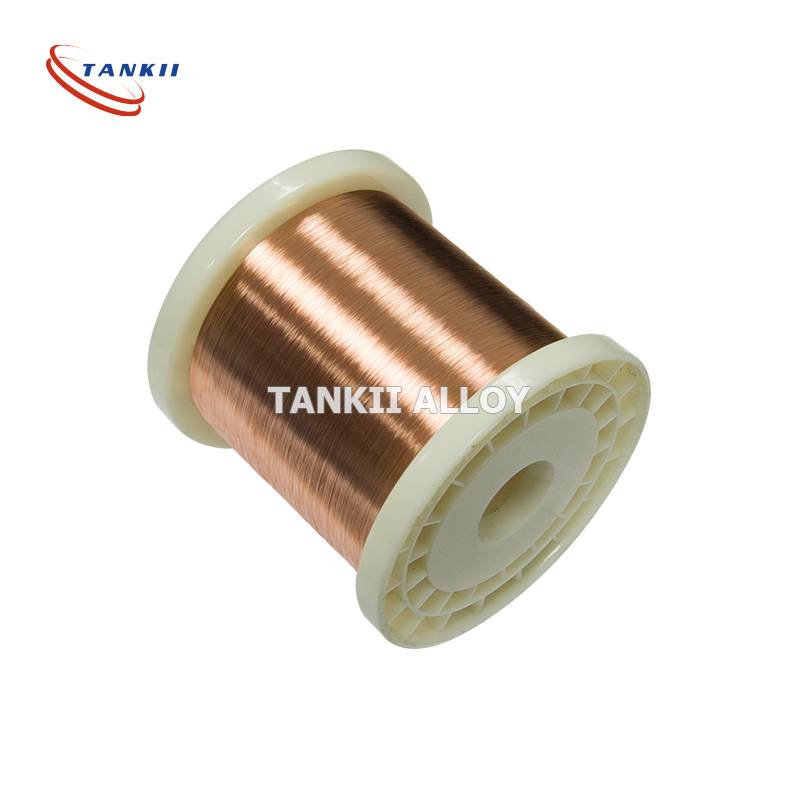

I-6J11 New Constantan Alloy Strip

Ukubuka Konke Komkhiqizo

I-6J11 entsha ye-constantan alloy strip iwumkhiqizo we-alloy wokumelana nokunemba okuphezulu othuthukiswe ngokuzimela yi-Tankii Alloy Material. Le alloy esekelwe ku-copper-nickel-manganese (Cu-Ni-Mn) ilungiselelwe ukusetshenziswa kokunemba kokushisa okuphakathi ngokusebenzisa i-vacuum smelting ethuthukisiwe, i-multi-pass precision cold-rolling, kanye nezinqubo zokulawula umoya.

Izici ezibalulekile zifaka:

- Izakhiwo zikagesi nezikamishini ezizinzile ngaphakathi kobubanzi bokusebenza obungu-0-120℃

- Ubuningi obungu-8.5g/cm³ kanye nokumelana okungu-0.49μΩ*m

- I-coefficient yokushisa okuphansi yokumelana (i-TCR)

- Ukumelana okuhle kakhulu nokugqwala kanye nokusebenza kahle kokucubungula

- Ilungele ama-resistor anembile, ama-current shunts, kanye nama-strain gauge kuma-electronics asetshenziswa ngabathengi, izinhlelo zokulawula zezimboni, kanye nezimoto

Izikhundla Ezijwayelekile kanye Nesisekelo Sezinto Ezibalulekile

- Ibanga le-Alloy: 6J11 (ibanga le-alloy entsha ye-constantan ejwayelekile yesiShayina)

- Ama-International Equivalents: Aqhathaniswa ne-DIN 17471 CuNi44Mn1.5 kanye ne-ASTM B193 modified constantan

- Amapharamitha Ayinhloko: 0-120℃ ububanzi bokusebenza; ukuminyana 8.5g/cm³; ukumelana 0.49μΩ*m (20℃)

- Izindinganiso Ezihambisanayo: GB/T 1234-2019, IEC 60404-8-2, kanye ne-RoHS 2.0

- Umkhiqizi: Izinto ze-Tankii Alloy (eziqinisekiswe yi-ISO 9001 kanye ne-ISO 14001)

Izinzuzo Eziyinhloko

1. Ukusebenza Okuzinzile Kukagesi Ebangeni Lokushisa Eliphakathi

- Ukumelana okuhlala njalo kugcinwe kuzinzile ku-0.49μΩ*m (20℃)

- I-TCR ephansi njenge-±15 ppm/℃ (ububanzi obungu-0-120℃)

- Ukumelana nokukhukhuleka <0.008% ngemva kwamahora ayi-1000 ku-120℃

2. Ukusebenza Okulinganiselwe Kwemishini Nokucubungula

- Ubuningi buka-8.5g/cm³ (12% ngaphansi kune-nickel-chromium alloys)

- Amandla okudonsa angu-480-550 MPa (isimo esihlanganisiwe)

- Ukwelulwa ≥25% ngekhono lokugoba elingu-180°

3. Ukugqwala Okuthembekile Nokuzivumelanisa Nemvelo

- Iphumelela ukuhlolwa kwe-ASTM B117 okufafazwa ngosawoti amahora ayi-1000

- Amandla aphansi okushisa komoya (≤2μV/℃ vs. ithusi)

- Iyamelana nokugqwala komoya, amanzi ahlanzekile, kanye nezindawo zamakhemikhali ezithambile

Imininingwane Yobuchwepheshe

| Isici | Inani (Elijwayelekile) | Ukubaluleka Kohlelo Lokusebenza |

|---|---|---|

| Ukwakheka Kwamakhemikhali (wt%) | Cu: 55.0-57.0%; Ni: 41.0-43.0%; Mn: 1.0-2.0% | Okuqukethwe kwe-Mn okwenzelwe ukuzinza kwe-TCR |

| Ubukhulu | 0.05-2.0mm (± 0.002mm ngo-≤0.2mm) | 0.05-0.1mm yama-micro-electronics |

| Ububanzi | 10-300mm (± 0.1mm ngo-≤100mm) | 10-50mm yezingxenye ezincane |

| Ukumelana (20℃) | 0.49μΩ*m (±0.02μΩ*m) | Ilinganisela ama-shunt wamanje angu-1-10A |

| Isilinganiso Sokushisa | ±15 ppm/℃ (0-120℃) | Iqinisekisa ukuqina kokumelana |

Imininingwane Yomkhiqizo

| Into | Imininingwane | Inzuzo Yokucubungula/Yokusebenzisa |

|---|---|---|

| Ukuqedwa Komphezulu | Ukuqeda okukhanyayo noma oku-matte | Kukhanya ukuze kuqoshwe ngokunemba; ku-matte ukuze kuvinjwe ukukhanya |

| Ukuthamba | ≤0.05mm/m | Iqinisekisa ukujiya okufanayo |

| Ifomu Lokunikeza | Ama-roll (50m-300m) noma anqunyiwe ubude (≥50mm) | Ama-roll okukhiqiza ngobuningi |

| Ukushibilika | Ifanelekela ukushisela amabala kanye ne-TIG | Ukwehluka kwamalunga ahlanganisiwe ≤0.1% |

Izicelo Ezijwayelekile

- Ama-Consumer Electronics: Ama-Micro-current shunts kuma-adapter ashaja ngokushesha (ubukhulu obungu-0.08-0.1mm)

- Izinhlelo Zezimoto: Ama-resistor azwa ugesi wamamojula okushaja i-USB emotweni

- Ukulawulwa Kwezimboni: Izinto zokumelana zama-transmitter okucindezela kanye namamitha okugeleza

- Amadivayisi Agqokwayo: Amagridi okulinganisa ukucindezeleka kuzinzwa zesilinganiso senhliziyo zewashi elihlakaniphile

Ukuqinisekisa ikhwalithi

I-Tankii Alloy Material isebenzisa ukulawulwa kwekhwalithi okuqinile okuhlanganisa:

- Ukuhlaziywa kokwakheka kwamakhemikhali e-XRF

- Ukuhlolwa kokumelana neprobe yamaphuzu amane okunembe kakhulu

- Umshini wokuhlola ojwayelekile wezakhiwo zemishini

- Imibiko yokuhlola yezinto ezibonakalayo (i-MTR) eningiliziwe iyatholakala

Bhala umlayezo wakho lapha bese uwuthumela kithi

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu