Intambo ye-Manganin engu-6J13 ene-enamel yokushisa okuphezulu ye-elekthronikhi

Intambo ye-Manganin 6j13 enameyili yokushisa okuphezulu ye-elekthronikhi

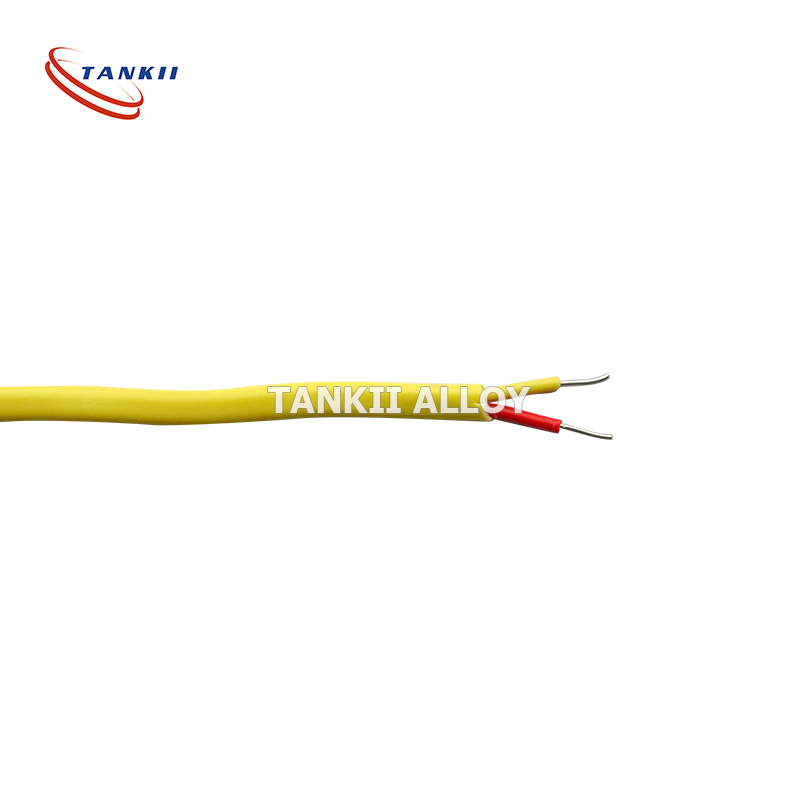

Ucingo oluzibuthe noma ucingo olune-enamel luwucingo lwethusi noma lwe-aluminium olumbozwe ngesendlalelo esincane kakhulu sokuvikela ukushisa. Lusetshenziswa ekwakhiweni kwama-transformer, ama-inductor, ama-motor, ama-generator, izikhulumi, ama-actuator ekhanda le-hard disk, ama-electromagnet, ama-pickup e-gitar kagesi kanye nezinye izinhlelo zokusebenza ezidinga ama-coil aqinile entambo evikela ukushisa ukushisa.

Intambo ngokwayo ivame kakhulu ukuba nethusi elicwengisiswe ngokuphelele, elicwengisiswe nge-electrolytic. Intambo kamagnethi ye-aluminium ngezinye izikhathi isetshenziselwa ama-transformer amakhulu nama-motor. Ukufakwa kokushisa ngokuvamile kwenziwa ngezinto zefilimu ye-polymer eqinile kune-enamel, njengoba igama lingase lisikisele.

Umqhubi

Izinto ezifanele kakhulu zokusetshenziswa kwentambo kamazibuthe yizinsimbi ezimsulwa ezingaxutshiwe, ikakhulukazi ithusi. Uma kucatshangelwa izici ezifana nezidingo zempahla yamakhemikhali, engokwenyama, kanye neyemishini, ithusi libhekwa njengomqhubi wokuqala okhethwayo wentambo kamazibuthe.

Ngokuvamile, ucingo olusebenzisa i-magnet luhlanganiswa nethusi elicwengisiswe ngokuphelele, elicwengisiswe nge-electrolytic ukuze kuvunyelwe ukugoqana eduze lapho kwenziwa ama-electromagnetic coil. Amazinga ethusi angenawo umoya-mpilo ahlanzekile kakhulu asetshenziselwa ukusetshenziswa kwezinga lokushisa eliphezulu ekunciphiseni umoya-mpilo noma kuma-motor noma ama-generator apholiswe yigesi ye-hydrogen.

Intambo kamagnethi ye-aluminium ngezinye izikhathi isetshenziswa njengenye indlela yama-transformer amakhulu nama-motor. Ngenxa yokuthi iphansi kakhulu ekuqhubeni kwayo ugesi, intambo ka-aluminium idinga indawo enkulu ngokuphindwe ka-1.6 kunentambo yethusi ukuze kufezwe ukumelana okufanayo kwe-DC.

Ukuvikela

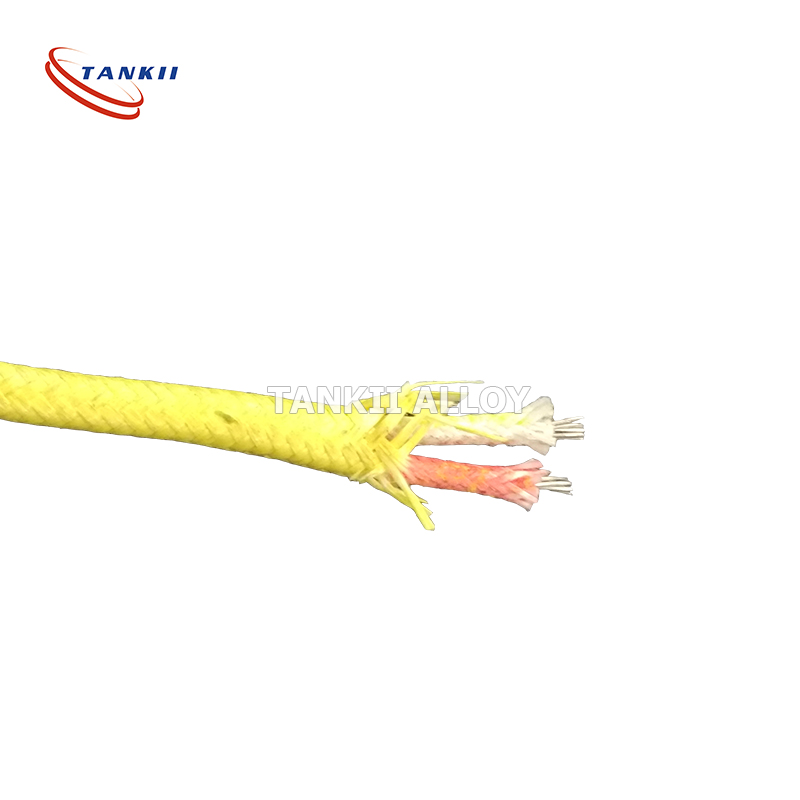

Nakuba kuchazwa ngokuthi “i-enameled”, intambo ene-enameled empeleni ayimboziwe ngesendlalelo sopende we-enamel noma i-vitreous enamel eyenziwe nge-fused glass powder. Intambo yesimanje yemagnet ngokuvamile isebenzisa isendlalelo esisodwa kuya kwezine (esimweni sentambo yohlobo lwe-quad-film) ye-polymer film insulation, evame ukuba nezingxenye ezimbili ezihlukene, ukuze inikeze isendlalelo esiqinile nesiqhubekayo sokuvikela. Amafilimu okuvikela intambo ene-magnet asebenzisa (ngokulandelana kokuphakama kwezinga lokushisa) i-polyvinyl formal (Formvar), i-polyurethane, i-polyamide, i-polyamide, i-polyamide, i-polyamide-polyimide, i-polyamide-polyimide (noma i-amide-imide), kanye ne-polyimide. Intambo yemagnet evikela i-polyimide iyakwazi ukusebenza kufika ku-250 °C. Ukuvikela intambo yemagnet eyisikwele noma engunxande ejiyile kuvame ukwandiswa ngokuyisonga nge-polyimide noma i-fiberglass tape enokushisa okuphezulu, futhi ama-winding aqediwe avame ukufakwa nge-vacuum nge-varnish evikelayo ukuze kuthuthukiswe amandla okuvikela kanye nokuthembeka kwesikhathi eside kwe-winding.

Amakhoyili azisekelayo aboshwe ngocingo olumbozwe okungenani ngezingqimba ezimbili, ingxenye engaphandle iyi-thermoplastic ebopha amajika ndawonye lapho eshiswa.

Ezinye izinhlobo zokuvikela ukushisa ezifana nentambo ye-fiberglass ene-varnish, iphepha le-aramid, iphepha le-kraft, i-mica, kanye nefilimu ye-polyester nazo zisetshenziswa kabanzi emhlabeni wonke ngezinhlelo zokusebenza ezahlukahlukene njenge-transformers kanye nama-reactor. Emkhakheni womsindo, ucingo lwesiliva olwakhiwe, kanye nezinye izinto zokuvikela ukushisa ezahlukahlukene, njengokotini (ngezinye izikhathi olugcwele uhlobo oluthile lwe-coagulating agent/thickener, njenge-beewax) kanye ne-polytetrafluoroethylene (Teflon) kungatholakala. Izinto zokuvikela ukushisa ezindala zazihlanganisa ukotini, iphepha, noma usilika, kodwa lezi ziwusizo kuphela ekusetshenzisweni kwezinga lokushisa eliphansi (kufika ku-105°C).

Ukuze kube lula ukukhiqiza, ucingo oluthile olusebenzisa amandla kagesi olusezingeni eliphansi lune-insulation engasuswa ngokushisa kwe-soldering. Lokhu kusho ukuthi ukuxhumeka kukagesi emaphethelweni kungenziwa ngaphandle kokususa i-insulation kuqala.

| Uhlobo Olufakwe Enamel | I-Polyester | I-Polyester Eguquliwe | i-polyester-imide | I-Polyamide-imide | i-polyester-imide / i-Polyamide-imide |

| Uhlobo Lokuvala Ukushisa | I-PEW/130 | I-PEW(G)/155 | I-EIW/180 | I-EI/AIW/200 | I-EIW(EI/AIW)220 |

| Isigaba sokushisa | 130, IKLASI B | 155, IKLASI F | 180, IKLASI H | 200, IKLASI C | 220, IKLASI N |

| Okujwayelekile | IEC60317-0-2IEC60317-29 MW36-A | IEC60317-0-2IEC60317-29MW36-A | IEC60317-0-2IEC60317-29 MW36-A | IEC60317-0-2IEC60317-29 MW36-A | IEC60317-0-2IEC60317-29 MW36-A |

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu