Siyakwamukela kumawebhusayithi ethu!

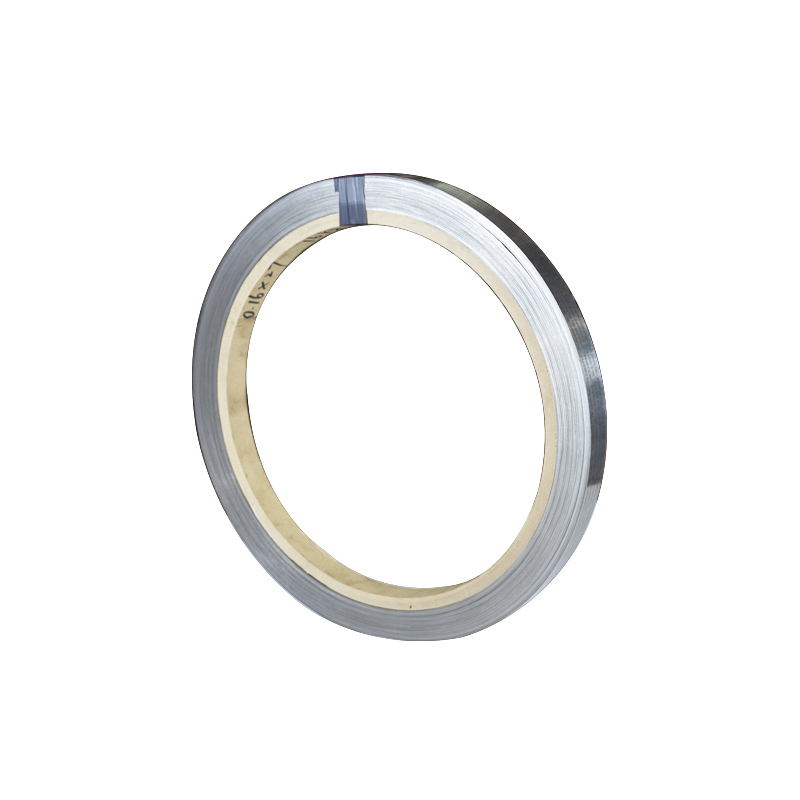

Isesitokweni I-ТБ2013/TM-2/108SP Bimetallic Strip Esezingeni Eliphezulu Yokulawula Isikhathi

Incazelo Yomkhiqizo

I-ТБ2013/TM-2/108SP Bimetallic Strip

Ukubuka Konke Komkhiqizo

I-ТБ2013/TM-2/108SP bimetallic strip, inhlanganisela esebenza kahle kakhulu eyakhiwe futhi yakhiqizwa yi-Tankii Alloy Material, iyibanga elikhethekile elilungiselelwe izimo zokushisa eziphakathi kuya kweziphezulu. Yakhiwe ngama-alloy amabili ahlukene anama-coefficients okukhulisa ukushisa alawulwa ngokunembile—ahlanganiswe ngobuchwepheshe bokusabalalisa obuhambisana nokushisa obuhamba phambili bukaHuona—le strip ihlanganisa izinzuzo ezintathu eziyinhloko: ukuphendula okuzinzile kokushisa, ukumelana okuhle kakhulu kokukhathala komshini, kanye nokuzivumelanisa nezimo okubanzi kwemvelo. Ngokungafani nama-bimetallic strips ajwayelekile, ibanga le-ТБ2013/TM-2/108SP lenzelwe ukulinganisela ukuzwela kokushisa kanye namandla esakhiwo, okwenza kube kuhle kakhulu kuma-thermostat ezimboni, izivikeli zokushisa ngokweqile zemoto, kanye nezingxenye zokunciphisa ukushisa okunembile ezindaweni zokusebenza ezinzima (isb., umswakama ophezulu, ukudlidliza).

Izikhundla Ezijwayelekile Nokwakheka Okuyinhloko

- Ibanga Lomkhiqizo: ТБ2013/TM-2/108SP

- Isakhiwo Esihlanganisiwe: Ngokuvamile siqukethe “ungqimba olunwebeka kakhulu” kanye “nongqimba olunwebeka kancane”; amandla okubopha phakathi kwe-interfacial ≥140 MPa

- Izindinganiso Ezihambisanayo: Zihambisana ne-GOST 28561-90 (izinga laseRussia lama-bimetallic strips) kanye ne-IEC 60694 yezingxenye zokulawula ukushisa; ziyahambisana nezidingo ze-EU RoHS

- Umkhiqizi: Izinto ze-Tankii Alloy, eziqinisekiswe yi-ISO 9001 kanye ne-ISO 14001, ezinekhono lokwakheka kwe-alloy ngaphakathi kanye nekhono lokubopha elihlanganisiwe ukuze lihambisane nezidingo zokusebenza ezithile zebanga.

Izinzuzo Eziyinhloko (uma kuqhathaniswa ne-Generic Bimetallic Strips)

I-ТБ2013/TM-2/108SP ivelele ngokusebenza kwayo okugxile ekusetshenzisweni, ibhekana nezinkinga ekusetshenzisweni kwezimboni kanye nemvelo enzima:

- Ukuzivumelanisa Nezimo Zokushisa Okubanzi: Isebenza ngokuqina ku--50℃ kuya ku-250℃ (ukusetshenziswa okuqhubekayo), ngokumelana kwesikhathi esifushane okufika ku-300℃—idlula imichilo ejwayelekile ye-bimetallic (ekhawulelwe ku-≤200℃) futhi ifanele izimo zezimboni ezishisa kakhulu (isb., izinzwa zezingxenye zenjini).

- I-Hysteresis Ephansi Yokushisa: Iphutha le-Hysteresis ≤3℃ (phakathi kwamaphuzu okusebenza okushisa nokupholisa) ku-150℃—okubalulekile ekulawuleni izinga lokushisa ngokunemba (isb., ama-thermostat e-oven ezimboni) lapho imijikelezo ephindaphindwayo yokuvula/ukuvala idinga imingcele efanayo.

- Ukumelana Okuqinile Nokukhathala: Imelana nemijikelezo yokushisa engu-≥15,000 (-50℃ kuya ku-250℃) ngaphandle kokuhlukanisa phakathi kobuso noma ukubola kokusebenza—impilo yesevisi ende ka-3× kunemichilo yezinga eliphansi, okunciphisa izindleko zokulungisa imishini yesevisi ende (isb., izinhlelo ze-HVAC).

- Ukumelana Nokudlidliza Nokugqwala: Amandla okujikijela ajikelezayo ≥460 MPa aqinisekisa ukuzinza kwesakhiwo ngaphansi kokudlidliza (kuyahambisana nokuhlolwa kokudlidliza kwe-IEC 60068-2-6); i-zinc-plating ekhethwayo inikeza ukumelana nokufuthwa kukasawoti amahora angama-96 (ASTM B117) ezindaweni ezinomswakama noma ezigqwalisayo (isb., imishini yasolwandle).

- Ukunemba Okulinganayo Kobukhulu: Kutholakala ngobukhulu obufanayo (0.15mm–0.8mm) kanye nobubanzi (10mm–200mm) ngokubekezelelana okungu-≤±0.005mm (ubukhulu) kanye no-≤±0.1mm (ububanzi)—okuvumela ukunyathelisa okuzenzakalelayo kanye nokuhlanganiswa ezingxenyeni ezijwayelekile zezimboni.

Imininingwane Yobuchwepheshe

| Isici | Inani (Elijwayelekile) |

|---|---|

| Ububanzi Bokujiya | 0.15mm – 0.8mm (okwenziwe ngokwezifiso kufika ku-1.2mm) |

| Ububanzi Bebanga | 10mm – 200mm (ububanzi obujwayelekile: 15mm, 20mm, 27mm) |

| Ubude ngeRoll ngayinye | 50m – 300m (kuyatholakala ubude obunqunyiwe: ≥100mm) |

| Isilinganiso Sokwanda Kokushisa (Ungqimba Oluphezulu/Oluphansi) | ~4:1 |

| Ibanga Lokushisa Lokusebenza | -50℃ kuya ku-250℃ (okuqhubekayo); Isikhathi esifushane: kufika ku-300℃ (≤ihora eli-1) |

| Ukuphambuka Kokushisa Kokusebenza | ±2℃ (esikhundleni sokulinganisa ukusebenza, 80℃–200℃) |

| Amandla Okugunda Okuphakathi Kobuso | ≥140 MPa |

| Amandla Okudonsa (Aguquguqukayo) | ≥460 MPa |

| Ukwelulwa (25℃) | ≥14% |

| Ukumelana (25℃) | 0.20 – 0.35 Ω·mm²/m |

| Ubulukhuni Bomphezulu (Ra) | ≤0.8μm (ukuqeda kwemishini); ≤0.4μm (ukuqeda okucwebezelisiwe, uma uthanda) |

Imininingwane Yomkhiqizo

| Into | Imininingwane |

|---|---|

| Ukuqedwa Komphezulu | Ukuqeda umshini wokugaya (ongena-oxide) noma i-zinc-plated/nickel-plated (ukuvikela ukugqwala okuthuthukisiwe) |

| Ukuthamba | ≤0.1mm/m (okubalulekile ekuguqulweni kokushisa okufanayo kanye nokunemba kokunyathela) |

| Ukusebenziseka kalula | Iyahambisana nokunyathela kwe-CNC, ukusika nge-laser, kanye nokugoba; akukho ukuqhekeka kwe-interfacial ngesikhathi sokucubungula (ubuncane be-radius yokugoba ≥3× ubukhulu) |

| Ikhwalithi Yokubopha | Ukubopha okungu-100% kobuso (akukho zimbobo >0.1mm², okuqinisekiswe ngokuhlolwa kwe-X-ray kanye nokuhlolwa kwe-ultrasonic) |

| Ukupakisha | Ivalwe nge-vacuum ezikhwameni ze-aluminium foil ezingangeni umswakama ezine-desiccant; izipuni zokhuni (zemiqulu) noma amabhokisi alwa nokugoba (amashidi asikiwe) ukuvimbela ukuguguleka |

| Ukwenza ngokwezifiso | Ukulungiswa kwezinga lokushisa lokusebenzisa (60℃–220℃), ukumbozwa kwendawo, izimo ezifakwe isitembu (ngamafayela e-CAD ekhasimende ngalinye), kanye nobukhulu/ububanzi obungejwayelekile |

Izicelo Ezijwayelekile

- Ukulawulwa Kokushisa Kwezimboni: Ama-thermostat ama-oven ezimboni, ama-boiler, kanye nezinhlelo ze-HVAC; abalawuli bokushisa bemishini yokubumba yepulasitiki (esebenza ku-120℃–200℃).

- Ukuvikelwa Kokushisa Okudlulele: Ama-thermal circuit breaker ezinjini zikagesi (isb., amaphampu ezimboni, ama-compressor) kanye nama-power transformer—avimbela ukusha ngokunqamula ama-circuit ku-150℃–250℃.

- Izimoto Nezasolwandle: Izinzwa zokushisa kanye nezivikelo zezingxenye zenjini (zezimoto) kanye nemishini yasolwandle (emelana nokudlidliza kanye nokugqwala kwamanzi anosawoti).

- Amathuluzi Okunemba: Izinto ezinciphisa izinga lokushisa zama-gauge okucindezela, amamitha okugeleza, kanye nezinzwa ze-MEMS—ziqeda amaphutha okukhulisa ukushisa ukuze kugcinwe ukunemba kokulinganisa.

- Izinto Zasekhaya Nezebhizinisi: Izivikelo zokushisa ngokweqile zama-heater amanzi kagesi, ama-air conditioner, kanye namafriji ebhizinisi (ukusebenza okuzinzile ezindaweni ezinomswakama ophezulu).

I-Tankii Alloy Material isebenzisa ukulawulwa kwekhwalithi okuqinile kwe-ТБ2013/TM-2/108SP bimetallic strips: ibhetshi ngayinye ihlolwa ukuhlolwa kokucheba kwe-interfacial, ukuhlolwa kokuqina kokushisa okungu-1000-cycle, ukuhlolwa kobukhulu (i-laser micrometry), kanye nokulinganiswa kokushisa kwe-actuation. Amasampula wamahhala (100mm×20mm) kanye nemibiko yokusebenza eningiliziwe (kufaka phakathi ukugoba kokushisa vs. ama-temperature curves) ayatholakala uma eceliwe. Ithimba lethu lobuchwepheshe linikeza ukwesekwa okwenzelwe wena—njengokwenza ngcono ungqimba lwe-alloy lwamazinga okushisa athile okusebenza kanye nesiqondiso sokuhambisana nezinqubo zokuhlanganisa izimboni—ukuqinisekisa ukuthi i-strip ihlangabezana nezidingo eziqondile zezicelo zezimboni zase-Eurasia nezomhlaba wonke.

Bhala umlayezo wakho lapha bese uwuthumela kithi

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu