Ngocingo lokumelana, amandla okumelana kwethu anganqunywa ngokuvumelana nokumelana nocingo lokumelana. Amandla ayo amakhulu, kungenzeka ukuthi abantu abaningi abazi ukuthi bangakhetha kanjani ucingo lokumelana, futhi alukho ulwazi oluningi mayelana nocingo lokumelana. , uXiaobian uzochazela wonke umuntu.

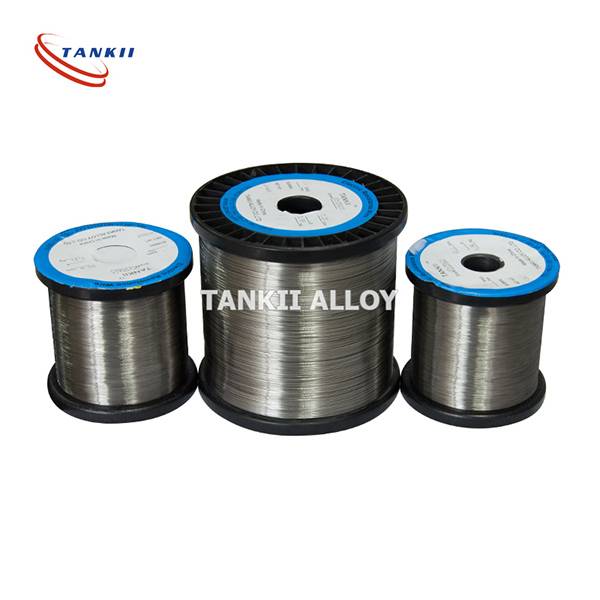

I-Resistance wire iwuhlobo oluvame kakhulu lwezinto zokushisisa. Umsebenzi wayo ukukhiqiza ukushisa ngemva kokunika amandla nokuguqula amandla kagesi abe ukushisa. I-Resistance wire inezinhlobonhlobo zezinhlelo zokusebenza. Amadivayisi amaningi asetshenziswa kakhulu okushisa kagesi asebenzisa intambo yokumelana njengesici sokushisa. Ngakho-ke, ucingo lokumelana lusetshenziswa kwezokwelapha, amakhemikhali, i-electronics, ugesi, imishini ye-metallurgical, i-ceramic glass processing kanye nezinye izimboni.

1. Isimiso sokusebenza socingo lokumelana

Isimiso sokusebenza socingo lokumelana siyafana nesamanye ama-elementi okushisisa insimbi, futhi yisenzakalo sokushisa kukagesi ngemva kokuba insimbi inikwe amandla. Ukushisa kagesi kusho ukuthi ngemva kokuba i-current idlule kumqhubi, i-current izokhiqiza inani elithile lokushisa futhi idluliselwe ngumqhubi. Intambo yokumelana ngokwayo iyi-conductor yensimbi, ezokhipha ukushisa futhi inikeze amandla okushisa ngemva kokunikwa amandla.

2. Ukuhlukaniswa kwentambo yokumelana

Izinhlobo zezintambo zokumelana zihlukaniswa ngokusho kokuqukethwe kwamakhemikhali kanye nesakhiwo senhlangano yocingo lokumelana. Kukhona izintambo ze-iron-chromium-aluminium alloy resistance nezintambo ze-nickel-chromium alloy resistance. Njengezinto zokushisa zikagesi, lezi zinhlobo ezimbili zezintambo zokumelana zinezici ezihlukile zokusebenza.

3. izici zocingo lokumelana

Intambo yokumelana ibonakala ngokumelana nokushisa okuphezulu, ukushisa okusheshayo, impilo ende yesevisi, ukumelana okuzinzile, ukuphambuka kwamandla amancane, i-uniform thread pitch ngemva kokwelula, kanye nendawo ekhanyayo nehlanzekile. Isetshenziswa kabanzi ezithandweni zikagesi ezincane, izifutho ze-muffle, izinto zokufudumeza nezomoya, amahhavini ahlukahlukene, amashubhu okushisa kagesi nezinto zikagesi zasendlini, njll. Imigoqo ehlukahlukene yezimboni neyomphakathi engajwayelekile ingaklanywa futhi ikhiqizwe ngokuya ngezidingo zomsebenzisi.

4. izinzuzo kanye nokubi kwe-iron-chromium-aluminium alloy resistance wire

I-iron-chromium-aluminium alloy resistance wire inenzuzo yezinga lokushisa eliphezulu lokusebenza. Ukuhlolwa kukhombisa ukuthi izinga lokushisa eliphezulu lokusebenza le-iron-chromium-aluminium alloy resistance wire lingafinyelela ku-1400°C. I-iron-chromium-aluminium alloy resistance wire inempilo ende yesevisi, ukumelana okuphezulu, ukuhlanganisa okuphezulu kwendawo, kanye nokumelana ne-oxidation okuhle.

Ububi be-iron-chromium-aluminium alloy resistance wire amandla ayo aphansi ezindaweni zokushisa okuphezulu. Njengoba izinga lokushisa likhuphuka, i-plasticity ye-iron-chromium-aluminium alloy resistance wire izokhula, okusho ukuthi i-iron-chromium-aluminium alloy resistance wire ijwayele ukuguquguquka emazingeni okushisa aphezulu. Futhi akulula ukulungisa ngemva kokuguqulwa.

5.izinzuzo kanye nokubi kwe-nickel-chromium alloy resistance wire

Izinzuzo zocingo lwe-nickel-chromium alloy resistance wire zingamandla aphezulu endaweni yokushisa ephezulu, ukusebenza kwesikhathi eside kwezinga lokushisa akulula ukulimaza, futhi akulula ukuguqula isakhiwo, kanye ne-plasticity evamile yokushisa kwe-nickel-chromium alloy resistance wire kuhle, futhi ukulungiswa ngemva kokuguqulwa kulula. Ngaphezu kwalokho, i-nickel-chromium alloy resistance wire ine-emissivity ephezulu, engeyona-magnetic, ukumelana nokugqwala okuhle nempilo ende yesevisi.

Ububi bentambo yokumelana ne-nickel-chromium alloy ukuthi izinga lokushisa lokusebenza alikwazi ukufinyelela izinga lentambo yokumelana yangaphambilini. Ukwakhiwa kwe-nickel-chromium alloy resistance wire kudinga ukusetshenziswa kwe-nickel. Intengo yale nsimbi iphakeme kuneyensimbi, i-chromium ne-aluminium. Ngakho-ke, izindleko zokukhiqiza ze-nickel-chromium alloy resistance wire ziphezulu uma kuqhathaniswa, okungahambisani nokulawulwa kwezindleko.

Isikhathi sokuthumela: Oct-30-2020