Impumelelo enkulu yemboni yezindiza ayinakuhlukaniswa nentuthuko kanye nokuthuthuka kobuchwepheshe bezinto zezindiza. Ukuphakama okuphezulu, isivinini esikhulu kanye nokushelela okuphezulu kwezindiza zempi kudinga ukuthi izinto zokwakha zendiza kumele ziqinisekise amandla anele kanye nezidingo zokuqina. Izinto zenjini zidinga ukuhlangabezana nesidingo sokumelana nokushisa okuphezulu, ama-alloy okushisa okuphezulu, izinto ezihlanganisiwe ezisekelwe ku-ceramic yizinto eziyinhloko.

Insimbi evamile ithambisa ngaphezu kuka-300℃, okwenza ingafaneleki ezindaweni ezishisa kakhulu. Ukuze kusetshenziswe kahle ukuguqulwa kwamandla aphezulu, kudingeka amazinga okushisa aphezulu naphezulu okusebenza emkhakheni wamandla enjini yokushisa. Kuye kwaklanywa ama-alloy okushisa aphezulu ukuze asebenze kahle emazingeni okushisa angaphezu kuka-600℃, futhi ubuchwepheshe buyaqhubeka nokukhula.

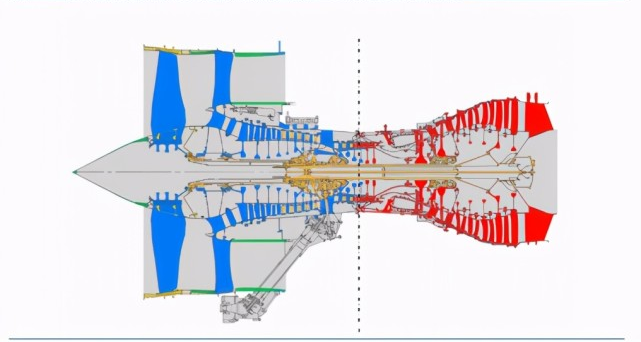

Ama-alloy okushisa okuphezulu ayizinto ezibalulekile zezinjini zezindiza, ezihlukaniswe ngama-alloy okushisa okuphezulu asekelwe ensimbini, asekelwe ku-nickel yizinto eziyinhloko ze-alloy. Ama-alloy okushisa okuphezulu asetshenziswe ezinjini ze-aero selokhu zasungulwa, futhi ayizinto ezibalulekile ekukhiqizweni kwezinjini zezindiza. Izinga lokusebenza kwenjini lincike kakhulu ezingeni lokusebenza kwezinto ze-alloy zokushisa okuphezulu. Ezinjini ze-aero zanamuhla, inani lezinto ze-alloy zokushisa okuphezulu libalelwa kumaphesenti angama-40-60 esisindo sonke senjini, futhi lisetshenziswa kakhulu ezingxenyeni ezine eziyinhloko ze-hot-end: amakamelo okushisa, ama-guides, ama-turbine blades nama-disc e-turbine, futhi ngaphezu kwalokho, lisetshenziselwa izingxenye ezifana nomagazini, amasongo, amakamelo okushisa amashaja kanye nama-nozzle omsila.

(Ingxenye ebomvu yomdwebo ikhombisa ama-alloy okushisa okuphezulu)

Ama-alloy asezingeni eliphezulu asekelwe ku-nickel Ngokuvamile isebenza ku-600 ℃ ngaphezu kwezimo zokucindezeleka okuthile, ayigcini nje ngokuba nokumelana okuhle nokugqwala kwezinga lokushisa eliphezulu, futhi inamandla aphezulu okushisa aphezulu, amandla okuhamba kanye namandla okukhuthazela, kanye nokumelana okuhle kokukhathala. Isetshenziswa kakhulu emkhakheni wezindiza kanye nezindiza ngaphansi kwezimo zokushisa okuphezulu, izingxenye zesakhiwo, njengezinsika zenjini yezindiza, amadiski e-turbine, amakamelo okushisa njalonjalo. Ama-alloy asekelwe ku-nickel angahlukaniswa abe ama-alloy asezingeni lokushisa eliphezulu aguquliwe, ama-alloy asezingeni lokushisa eliphezulu kanye nama-alloy amasha asezingeni lokushisa eliphezulu ngokwenqubo yokukhiqiza.

Uma izinga lokushisa lokusebenza kwe-alloy engamelana nokushisa liphezulu kakhulu, izinto eziqinisayo ku-alloy ziya ngokuya zikhula, lapho ukwakheka kuyinkimbinkimbi kakhulu, okuholela ekutheni ezinye i-alloy zingasetshenziswa kuphela esimweni sokubumba, azikwazi ukuguqulwa zibe yi-hot processing. Ngaphezu kwalokho, ukwanda kwezinto ezixubayo kwenza i-alloy esekelwe ku-nickel iqine ngokuhlukaniswa okukhulu kwezingxenye, okuholela ekungalingani kwenhlangano kanye nezakhiwo.Ukusetshenziswa kwenqubo yokusansimbi yempuphu ukukhiqiza ama-alloy okushisa okuphezulu, kungaxazulula izinkinga ezingenhla.Ngenxa yezinhlayiya ezincane zempuphu, isivinini sokupholisa impuphu, ukuqeda ukuhlukaniswa, ukuthuthuka kokusebenza okushisayo, ingxubevange yokuqala yokuphonsa ibe ukuguqulwa okushisayo okusebenzayo kwama-alloy anokushisa okuphezulu, amandla okukhiqiza kanye nezakhiwo zokukhathala ziyathuthuka, ingxubevange yempuphu enokushisa okuphezulu yokukhiqizwa kwama-alloy anokushisa okuphezulu ikhiqize indlela entsha.

Isikhathi sokuthunyelwe: Jan-19-2024