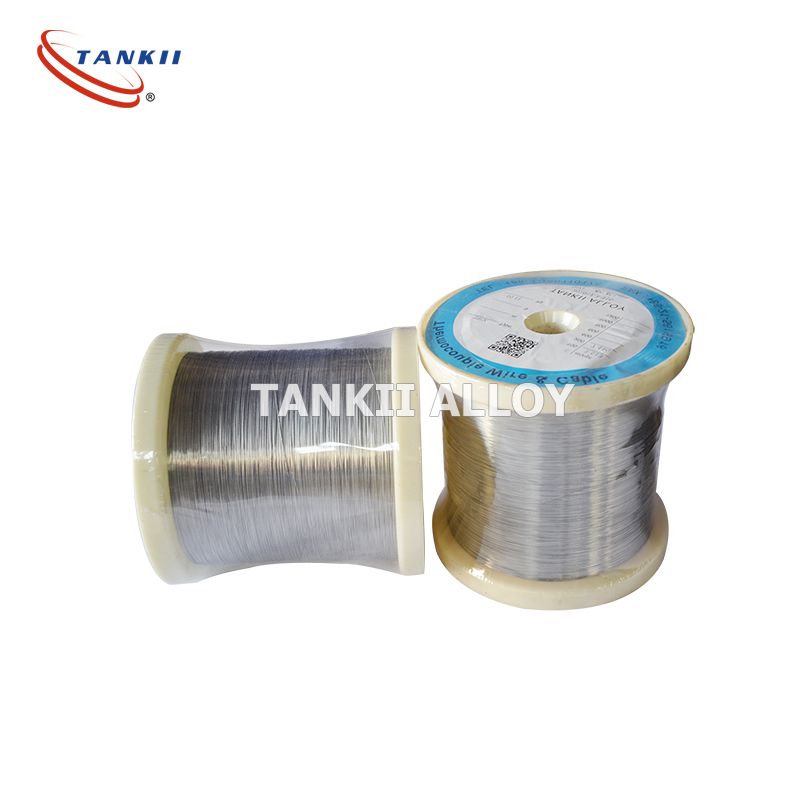

Ucingo lwe-alloy lwe-chrome lwe-nickel Ni70Cr30

Intambo ye-alloy ye-chrome ye-nickelI-Ni70Cr30

I-Cr30Ni70 Nichrome Alloy Eletrothermal Coil Strip, Ukumelana Okungaguquguquki Kwe-Heating Element,

I-NiCr70/30

I-alloy ye-nickel chromium enokumelana nensimbi nokushisa okuphezulu, ukumelana komzimba ongaphezulu kocansi. Uma izinga lokushisa liphezulu kanye namandla aphezulu,

kanye nokusebenza kahle kanye nokucubungula kungase kube ukushisela imvelo esetshenziswa kabanzi izinsimbi, ugesi, izingxenye zemishini kanye nogesi

izimboni zokukhiqiza zokwenza izinto ezimelana nokushisa.

Uhlobo lwe-NiCr: Cr20Ni80, Cr15Ni60, Cr20Ni35, Cr20Ni30, Cr25Ni20 njll. Ibhande likagesi eliyisicaba, ucingo lomlilo lukagesi.

3. Usayizi womkhiqizo:

Ubukhulu: 0.02—-4.0mm

Ububanzi: 2.5—-250mm

Okujwayelekile: GB1234-95

Ubuso obukhanyayo nobubushelelezi

I-Ni70Cr30

Okuqukethwe Kwamakhemikhali, %

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Okunye |

| Ubuningi | |||||||||

| 0.08 | 0.02 | 0.015 | 0.60 | 0.75~1.60 | 28.0~31.0 | Ibhalansi. | Umkhawulo ongu-0.50 | Ubuningi obungu-1.0 | - |

![]()

![]()

![]()

![]()

Izakhiwo Zemishini

| Izinga Lokushisa Eliphezulu Lesevisi Eqhubekayo: Ukuqina (20ºC)/Ω·m::Ubuningi: Ukuqhuba Ukushisa: Isilinganiso Sokwanda Kokushisa: Indawo Yokuncibilika: Ukwelulwa: Isakhiwo se-Micrographic: Impahla Kamagnetic: | 1250ºC 1.18 +/-0.05 (Ububanzi: <0.5mm) 1.20+/-0.05 (Ukudaya: ≥0.50 mm) 8.1 g/cm3 45.2 KJ/m·h·ºC 17×10-6/ºC (20ºC~1000ºC) 1380ºC Ubuncane obungu-20% I-Austenite okungeyona i-magnetic |

![]()

![]()

![]()

![]()

| Uhlobo | I-Cr20Ni80 | I-Cr15Ni60 | I-Cr30Ni70 | I-Cr20Ni35 | I-Cr20Ni30 | |

| Ukwakheka kwamakhemikhali okuyinhloko | Ni | Ukuphumula | 55.0~61.0 | Ukuphumula | 34.0~37.0 | 30.0~34.0 |

| Cr | 20.0~23.0 | 15.0~18.0 | 28.0~31.0 | 18.0~21.0 | 18.0~21.0 | |

| Fe | ≤1 | Ukuphumula | ≤1 | Ukuphumula | Ukuphumula | |

| Izinga Lokushisa Eliphezulu (ºC) | 1200 | 1150 | 1250 | 1100 | 1100 | |

| Isilinganiso sokulungiswa kwezinga lokushisa lokumelana. (CT) | 1.09±0.05 | 1.11±0.05 | 1.18±0.05 | 1.04±0.05 | 1.06±0.05 | |

| Indawo yokuncibilika (ºC) | 1400 | 1390 | 1380 | 1390 | 1390 | |

| Ukumelana ρ20ºC(10-6Ω.m) | 800ºC | 1.008 | 1.078 | 1.028 | 1.188 | 1.173 |

| 1000ºC | 1.014 | 1.095 | 1.033 | 1.219 | 1.201 | |

| 1200ºC | 1.025 | 1.043 | ||||

| Inani lempilo esheshayo | Isikhathi (ºC) | 1175 | 1100 | 1200 | 1050 | 1050 |

| ihora(h) | ≥110 | ≥100 | ≥110 | ≥100 | ≥100 | |

| Amandla adonsela phansi athile (g/cm3) | 8.40 | 8.2 | 8.1 | 7.90 | 7.90 | |

| Ukwelulwa (%) | ≥25 | ≥25 | ≥20 | ≥20 | ≥20 | |

| Ukushisa (kj/mhºC) | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Ukushisa okuqondile(20ºC)j/g.ºC | 0.440 | 0.494 | 0.461 | 0.500 | 0.500 | |

| Nweba amandla (20~1000ºC)α*10-6ºC | 18.0 | 17.0 | 17.1 | 19.0 | 19.0 | |

| Amandla okuqina (kg/mm2) | >85 | >85 | >85 | >85 | >85 | |

| Ukugoba ngokuphindaphindiwe (F/R) | >12 | >12 | >12 | >12 | >12 | |

| Isakhiwo esincane | I-Austenitic | I-Austenitic | I-Austenitic | I-Austenitic | I-Austenitic | |

![]()

![]()

![]()

![]()

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu