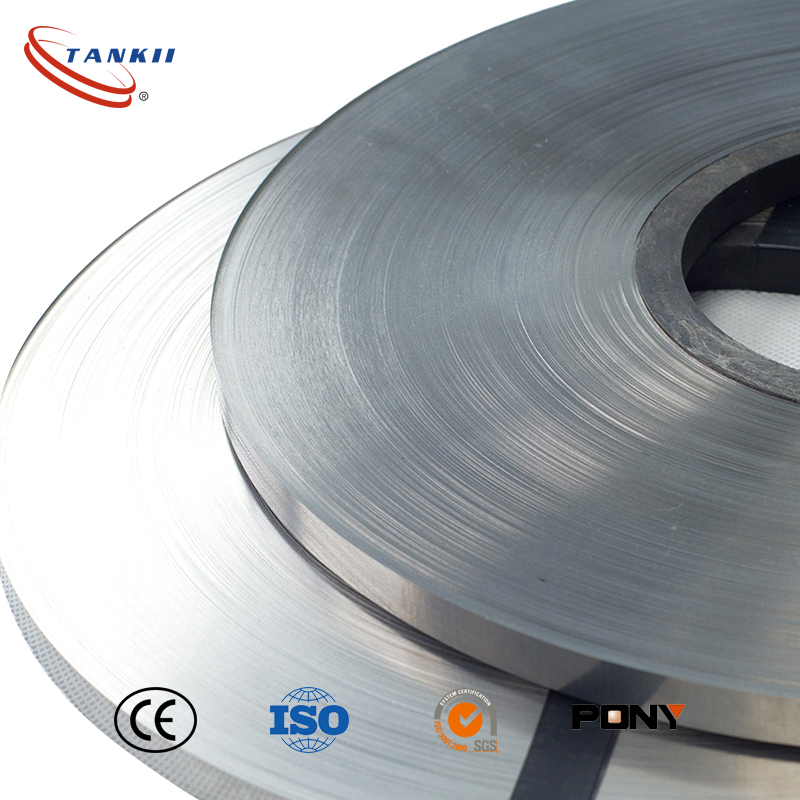

Itheyiphu ye-Nickel Chromium Alloy Cr20Ni80 Strip Nichrome Ni80Cr20

Incazelo Yomkhiqizo

I-NI90Cr10, eyaziwa nangokuthi i-Nichrome 90 noma i-NiCr 90/10, iyi-alloy esebenza kahle kakhulu enikeza ukumelana okuhle kakhulu namazinga okushisa aphezulu kanye nokugqwala. Inezinga lokuncibilika eliphakeme elingaba ngu-1400°C (2550°F) futhi ingagcina amandla ayo kanye nokuqina kwayo ngisho noma amazinga okushisa angaphezu kuka-1000°C (1832°F).

Le ngxube ivame ukusetshenziswa ezinhlelweni ezidinga izinto zokushisa, njengezitofu zezimboni, ama-oven, kanye nezinto zokushisa. Iphinde isetshenziswe ekukhiqizweni kwama-thermocouple, asetshenziselwa ukukala izinga lokushisa ezinqubweni ezahlukahlukene zezimboni.

I-NI90Cr10 inokumelana okuhle kakhulu ne-oxidation, okwenza ibe usizo ikakhulukazi ezindaweni ezishisa kakhulu lapho ezinye izinto zingagqwala futhi zonakale ngokushesha. Iphinde ibe nezakhiwo ezinhle zemishini, njengamandla aphezulu okudonseka kanye nokuguquguquka okuhle, okwenza kube lula ukwakheka nokuma.

Uma kukhulunywa ngamapayipi enziwe ngale ngxubevange, avame ukusetshenziswa ezindaweni lapho kukhona khona izimo zokushisa okuphezulu kanye nokugqwala, njengasezimbonini zokucubungula amakhemikhali, izimboni ze-petrochemical, kanye nokukhiqiza ugesi. Izakhiwo ezithile zepayipi, njengosayizi walo, ukujiya kodonga, kanye nesilinganiso sokucindezela, zizoncika ekusetshenzisweni okuhlosiwe kanye nezidingo ezithile zephrojekthi.

| Ukusebenza\ izinto | I-Cr10Ni90 | I-Cr20Ni80 | I-Cr30Ni70 | I-Cr15Ni60 | I-Cr20Ni35 | I-Cr20Ni30 | |

| Ukwakheka | Ni | 90 | Ukuphumula | Ukuphumula | 55.0~61.0 | 34.0~37.0 | 30.0~34.0 |

| Cr | 10 | 20.0~23.0 | 28.0~31.0 | 15.0~18.0 | 18.0~21.0 | 18.0~21.0 | |

| Fe | ≤1.0 | ≤1.0 | Ukuphumula | Ukuphumula | Ukuphumula | ||

| Izinga lokushisa eliphakeme kakhuluºC | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Iphuzu lokuncibilika ºC | 1400 | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Ubuningi g/cm3 | 8.7 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Ukumelana nokushisa ku-20ºC((μΩ·m) | 1.09±0.05 | 1.18±0.05 | 1.12±0.05 | 1.00±0.05 | 1.04±0.05 | ||

| Ukwelula lapho kuqhekeka | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

| Ukushisa okukhethekile I-J/g.ºC | 0.44 | 0.461 | 0.494 | 0.5 | 0.5 | ||

| Ukuqhuba kwe-thermal I-KJ/m.hºC | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | ||

| Ukwandiswa kwe-Coefficient yemigqa a×10-6/ (20~1000ºC) | 18 | 17 | 17 | 19 | 19 | ||

| Isakhiwo se-Micrographic | I-Austenite | I-Austenite | I-Austenite | I-Austenite | I-Austenite | ||

| Izakhiwo zikamazibuthe | Okungeyona i-magnetic | Okungeyona i-magnetic | Okungeyona i-magnetic | Amandla kazibuthe abuthakathaka | Amandla kazibuthe abuthakathaka | ||

Amapayipi e-NI90Cr10 avame ukusetshenziswa ezinhlotsheni lapho kukhona khona izimo zokushisa okuphezulu kanye nokugqwala, njengasezimbonini zokucubungula amakhemikhali, i-petrochemical, kanye nokukhiqiza ugesi. Lawa mapayipi aziwa ngokumelana kwawo okuhle kakhulu ne-oxidation kanye nokugqwala, okwenza abe afanele ukusetshenziswa ezindaweni ezifaka izixazululo ze-acidic noma ze-alkaline. Ezinye zezindlela ezithile zokusebenzisa amapayipi e-NI90Cr10 zifaka:

- Ukucubungula ngamakhemikhali: Amapayipi e-NI90Cr10 avame ukusetshenziswa ekucubungulweni kwamakhemikhali lapho kukhona khona izimo zokushisa okuphezulu kanye nokugqwala. Lawa mapayipi angasetshenziswa ukuthutha amakhemikhali agqwala futhi angamelana nokuchayeka ezixazululweni ze-acidic noma ze-alkaline.

- Amakhemikhali: Amapayipi e-NI90Cr10 asetshenziswa futhi embonini yamakhemikhali kaphethiloli, lapho asetshenziswa khona ekukhiqizeni uwoyela negesi. Angamelana namazinga okushisa aphezulu kanye nengcindezi futhi amelana nokugqwala, okwenza abe afanele ukusetshenziswa ezindaweni ezinzima.

- Ukukhiqizwa kukagesi: Amapayipi e-NI90Cr10 asetshenziswa ekusetshenzisweni kokukhiqizwa kukagesi njengakuma-turbine egesi kanye nama-turbine anomusi. Lawa mapayipi angamelana nezimo zokushisa okuphezulu kanye nokucindezela okuphezulu futhi amelana nokugqwala, okwenza abe afanele ukusetshenziswa ezitshalweni zikagesi.

- Izindiza: Amapayipi e-NI90Cr10 asetshenziswa nasezinhlelweni zezindiza lapho kukhona khona izimo zokushisa okuphezulu kanye nokugqwala. Lawa mapayipi angasetshenziswa ezinjinini zejethi, ezinjinini zerokhethi, nakwezinye izingxenye zezindiza ezisebenza kahle kakhulu.

Izakhiwo ezithile zamapayipi e-NI90Cr10, njengosayizi wawo, ukujiya kodonga, kanye nesilinganiso sokucindezela, kuzoncika ekusetshenzisweni okuhlosiwe kanye nezidingo ezithile zephrojekthi. Amapayipi angenziwa ngokwezifiso ukuze ahlangabezane nezidingo ezithile zohlelo lokusebenza, njengezinga lokushisa elidingekayo kanye nobubanzi bokucindezela, uhlobo loketshezi noma igesi, kanye nezimo zemvelo. Sekukonke, inhlanganisela eyingqayizivele yokumelana nokushisa okuphezulu, amandla omshini, kanye nokumelana nokugqwala kwenza amapayipi e-NI90Cr10 abe yinto ewusizo yezinhlelo zokusebenza ezahlukahlukene ezisebenza kahle ezimbonini ezahlukene.

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu