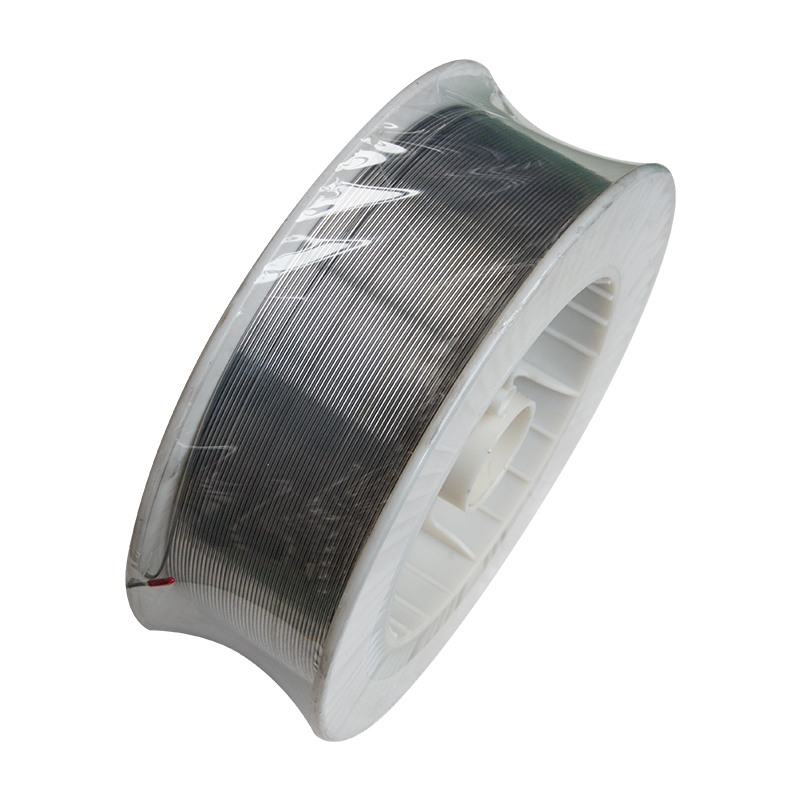

I-Nife 52 / ASTM F30 / Nilo 52 / 52h / N52 Fe-Ni Intambo Ye-Alloy Yokukhulisa Okuqhubekayo

I-Alloy 52 Iqukethe i-nickel engu-52% kanye ne-iron engu-48% futhi isetshenziswa kabanzi embonini yezokuxhumana. Iphinde isetshenziswe ezinhlotsheni eziningi zezinhlelo zokusebenza ze-elekthronikhi, ikakhulukazi ezivalweni zengilazi.

I-Alloy 52 ingenye yezinsimbi zokuvala ingilazi eziklanyelwe ukusetshenziswa nezinhlobonhlobo zezibuko ezithambile. Yaziwa ngokwandisa ukushisa okufana nokushisa okucishe kufane kuze kufike ku-1050F (565 C).

Ububanzi Bosayizi:

*Ishidi—Ubukhulu 0.1mm ~ 40.0mm, ububanzi: ≤300mm, Isimo: i-cold rolled (eshisayo), ekhanyayo, ekhanyayo

*Intambo Eyindilinga—Ububanzi obungu-0.1mm~Ububanzi obungu-5.0mm,Isimo: idonswa kubanda, ikhanya, i-annealed ekhanyayo

*Intambo Eyisicaba—Ububanzi obungu-0.5mm ~ Ububanzi obungu-5.0mm, ubude: ≤1000mm, Isimo: sigoqekile, sicwebezelisiwe

*Ibha—Ububanzi obungu-5.0mm ~ Ububanzi obungu-8.0mm, ubude: ≤2000mm, Isimo: sidonswe kubanda, sikhanya, sicwebezela

Ububanzi obungu-8.0mm ~ Ububanzi obungu-32.0mm, ubude: ≤2500mm, Isimo: sishisiwe, sikhanya, sicwebezela

Ububanzi obungu-32.0mm ~ Ububanzi obungu-180.0mm, ubude: ≤1300mm, Isimo: ukushisa, okuhlutshiwe, okuphendukile, okushisiwe

*I-Capillary—OD 8.0mm~1.0mm,ID 0.1mm~8.0mm,ubude:≤2500mm,Isimo: idonswe kubanda, ikhanya, i-annealed ekhanyayo.

*Ipayipi—OD 120mm~8.0mm,ID 8.0mm~129mm,ubude:≤4000mm,Isimo: idonswe kubanda, ikhanya, i-annealed ekhanyayo.

Ikhemistri:

| Cr | Al | C | Fe | Mn | Si | P | S | Ni | Mg | |

| Ubuncane | – | – | – | – | – | – | – | – | 50.5 | – |

| Ubuningi | 0.25 | 0.10 | 0.05 | Ibhalansi. | 0.60 | 0.30 | 0.025 | 0.025 | – | 0.5 |

Isilinganiso Sokukhulisa Okuqondile:

| Ibanga | α1/10-6ºC-1 | |||||||

| 20~100ºC | 20~200ºC | 20~300ºC | 20~350ºC | 20~400ºC | 20~450ºC | 20~500ºC | 20~600ºC | |

| 4J52 | 10.3 | 10.4 | 10.2 | 10.3 | 10.3 | 10.3 | 10.3 | 10.8 |

Izakhiwo:

| Isimo | Amandla okudonsa acishe abe khona | Izinga lokushisa lokusebenza elilinganiselwe | ||

| N/mm² | ksi | °C | °F | |

| I-Annealed | 450 – 550 | 65 – 80 | kufika ku-+450 | kufika ku-+840 |

| Kudwetshwe Kanzima | 700 – 900 | 102 – 131 | kufika ku-+450 | kufika ku-+840 |

| Ukwakheka: |

| Ingxubevange inokuguquguquka okuhle futhi ingakhiwa ngezindlela ezijwayelekile. |

| Ukushisela: |

| Ukushisela ngezindlela ezivamile kufanelekile kule ngxubevange. |

| Ukwelashwa Kokushisa: |

| I-alloy 52 kufanele ifakwe ku-1500F kulandelwe ukupholisa umoya. Ukunciphisa ukucindezeleka okuphakathi kungenziwa ku-1000F. |

| Ukwakha: |

| Ukufakelwa kufanele kwenziwe ekushiseni okungu-2150 F. |

| Ukusebenza Okubandayo: |

| Ingxube ilula ukuyisebenzisa. Izinga lokudweba elijulile kufanele lichazwe kulowo msebenzi wokwakha kanye nezinga lokufaka elihlanganisiwe lokwakha okuvamile. |

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu