Siyakwamukela kumawebhusayithi ethu!

Ukuhlinzekwa Kobungcweti kweRibhoni ye-ASTM TM2 Bimetallic, Ukusebenza Okuzinzile Nokwethembekile

Incazelo Yomkhiqizo

I-ASTMI-TM2iribhoni ye-bimetalIgama Elivamile: Truflex P675R, Chace 7500,Telcon200, Kan 200)

I-ASTM TM2 ye-Bimetallic inamandla okuzwela ukushisa okuphezulu kakhulu kanye nokumelana okuphezulu, kodwa i-modulus yokunwebeka kanye nokucindezeleka okuvumelekile iphansi, ingathuthukisa ukuzwela kwethuluzi, yehlise usayizi futhi inyuse amandla.

I-ASTM TM2 ye-Bimetallic inamandla okuzwela ukushisa okuphezulu kakhulu kanye nokumelana okuphezulu, kodwa i-modulus yokunwebeka kanye nokucindezeleka okuvumelekile iphansi, ingathuthukisa ukuzwela kwethuluzi, yehlise usayizi futhi inyuse amandla.

Ukwakheka

| Ibanga | I-ASTM TM2 |

| Isendlalelo sokunwebeka okuphezulu | I-Mn75Ni15Cu10 |

| Isendlalelo sokunwebeka esiphansi | I-Ni36 |

Ukwakheka kwamakhemikhali(%)

| Ibanga | C | Si | Mn | P | S | Ni | Cr | Cu | Fe |

| I-Ni36 | ≤0.05 | ≤0.3 | ≤0.6 | ≤0.02 | ≤0.02 | 35~37 | - | - | Ibhalansi. |

| Ibanga | C | Si | Mn | P | S | Ni | Cr | Cu | Fe |

| I-Mn72Ni10Cu18 | ≤0.05 | ≤0.5 | Ibhalansi. | ≤0.02 | ≤0.02 | 9~11 | - | 17~19 | ≤0.8 |

Izakhiwo Ezijwayelekile Zomzimba

| Ubuningi (g/cm3) | 7.7 |

| Ukumelana kukagesi ku-20ºC(ohm mm2/m) | 1.13 ±5% |

| Ukushisa, λ/ W/(m*ºC) | 6 |

| I-Elastic Modulus, E/ Gpa | 113~142 |

| Ukugoba K / 10-6 ºC-1(20~135ºC) | 20.8 |

| Izinga lokugoba lokushisa F/(20~130ºC)10-6ºC-1 | 39.0%±5% |

| Izinga lokushisa elivumelekile (ºC) | -70~ 200 |

| Izinga lokushisa eliqondile (ºC) | -20~ 150 |

Isicelo:Le nto isetshenziswa kakhulu njengezinto zokuvala i-ceramic ezingezona ezikagesi ezingafani ne-magnetic ku-Gyro nakwamanye amadivayisi kagesi okuhlanza.

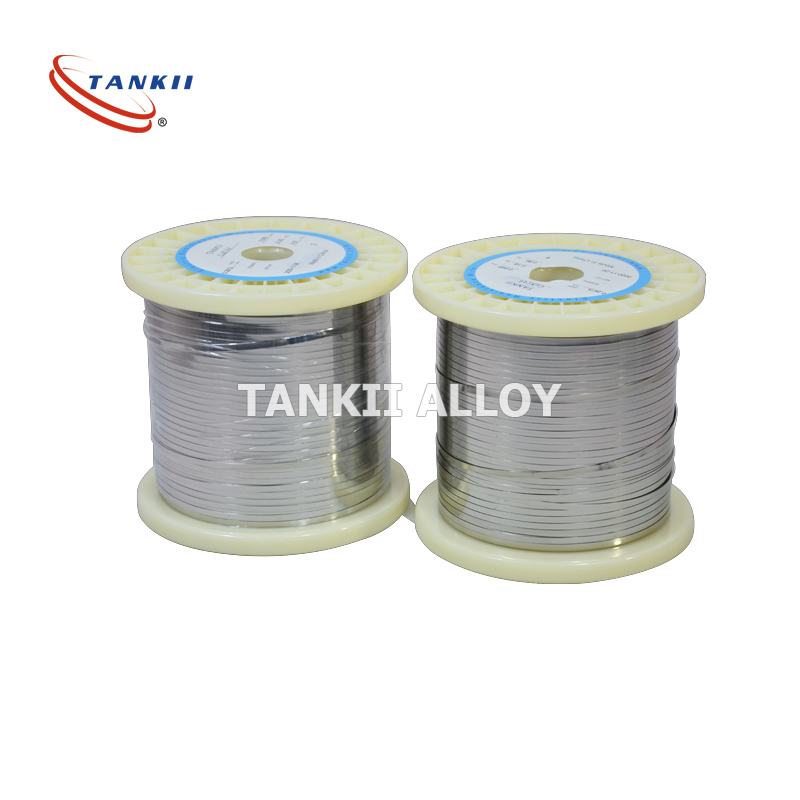

Isitayela sokunikezwa

| Igama le-Alloys | Uhlobo | Ubukhulu | ||

| I-ASTM TM2 | Ukuhlubula | W= 5~120mm | T= 0.1mm | |

Bhala umlayezo wakho lapha bese uwuthumela kithi

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu