Siyakwamukela kumawebhusayithi ethu!

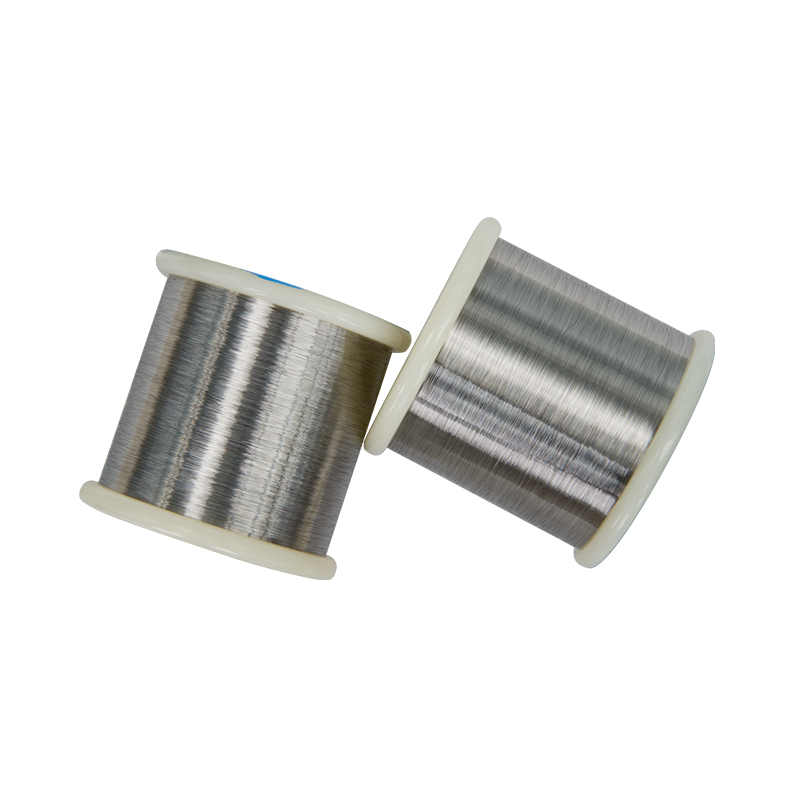

I-PTC Thermistor Alloy Resistance NiFe28 NiFe30 Wire ingeye-Temperature Sensitive Resistance

Intambo ye-PTC Alloy inokumelana okumaphakathi kanye ne-coefficient ephezulu yokushisa ephozithivu yokumelana. Isetshenziswa kabanzi kuma-heaters ahlukahlukene. Ingakwazi ukulawula izinga lokushisa ngokuzenzakalelayo futhi ilungise amandla ngokugcina amanje angashintshi kanye nomkhawulo wamanje. Ingxubevange ye-PTC inezinzuzo eziningi ezifana nokulawula izinga lokushisa okuzenzakalelayo, ukulawula amandla okuzenzakalelayo, amandla angashintshi, umkhawulo wamanje, ukonga amandla kanye nempilo ende yokusebenza.

Singakhiqiza izinhlobo eziningi zezintambo zokumelana ne-PTC. Amanye amaklayenti abiza izintambo ze-NiFe esikhundleni sezintambo ze-PTC.

Uma unezidingo ezikhethekile ku-Tem.Coeff ne-Resistivity kanye nobubanzi, sicela ukhululeke ukusazisa. Singakwenzela ngendlela oyifisayo. Njengokuthi,

I-NF13–Ukumelana 0.13μΩm,Tem. Coef. kokumelana3400-3600PPm(Ni90).

Ni89.8% Mn0.2% Fe10%

Njengo, 0.05mm ububanzi PTC-4500

I-NF13–Ukumelana 0.13μΩm,Tem. Coef. kokumelana3400-3600PPm(Ni90).

Ni89.8% Mn0.2% Fe10%

Njengo, 0.05mm ububanzi PTC-4500

| Ikhodi | Ububanzi mm | ||

| Intambo | Induku | Intambo yocingo | |

| NF13 | 0.05-8.0 | 12-30 | 8-14 |

| NF15 | 0.05-8.0 | 12-30 | 8-14 |

| NF20 | 0.05-8.0 | 12-30 | 8-14 |

| NF23 | 0.05-8.0 | 12-30 | 8-14 |

| NF25 | 0.05-8.0 | 12-30 | 8-14 |

| NF32 | 0.05-8.0 | 12-30 | 8-14 |

| NF36 | 0.05-8.0 | 12-30 | 8-14 |

| NF38 | 0.05-8.0 | 12-30 | 8-14 |

| NF40 | 0.05-8.0 | 12-30 | 8-14 |

| NF43 | 0.05-8.0 | 12-30 | 8-14 |

| NF46 | 0.05-8.0 | 12-30 | 8-14 |

| NF52 | 0.05-8.0 | 12-30 | 8-14 |

| NF60 | 0.05-8.0 | 12-30 | 8-14 |

| I-alloy brand | Isici samakhemikhali | |

| Ngingu-100% | Fe 100% | |

| NF13 | 85-95 | Phumula |

| NF15 | 75-85 | Phumula |

| NF20 | 70-75 | Phumula |

| NF23 | 60-65 | Phumula |

| NF25 | 60-65 | Phumula |

| NF32 | 50-55 | Phumula |

| NF36 | 50-55 | Phumula |

| NF38 | 50-55 | Phumula |

| NF40 | 50-55 | Phumula |

| NF43 | 45-50 | Phumula |

| NF46 | 45-50 | Phumula |

| NF52 | 45-50 | Phumula |

| NF60 | 45-50 | Phumula |

| I-alloy brand | 20ºC ukumelana | Ibanga lokubekezelelana |

| NF13 | 0.13 | ±0.02 |

| NF15 | 0.15 | ±0.02 |

| NF20 | 0.20 | ±0.02 |

| NF23 | 0.23 | ±0.02 |

| NF25 | 0.25 | ±0.02 |

| NF32 | 0.32 | ±0.02 |

| NF36 | 0.36 | ±0.02 |

| NF38 | 0.38 | ±0.02 |

| NF40 | 0.40 | ±0.02 |

| NF43 | 0.43 | ±0.02 |

| NF46 | 0.46 | ±0.02 |

| NF52 | 0.52 | ±0.02 |

| NF60 | 0.60 | ±0.02 |

Bhala umlayezo wakho lapha futhi usithumelele wona

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

Whatsapp

-

I-WeChat

Judy

150 0000 2421

-

Phezulu