Siyakwamukela kumawebhusayithi ethu!

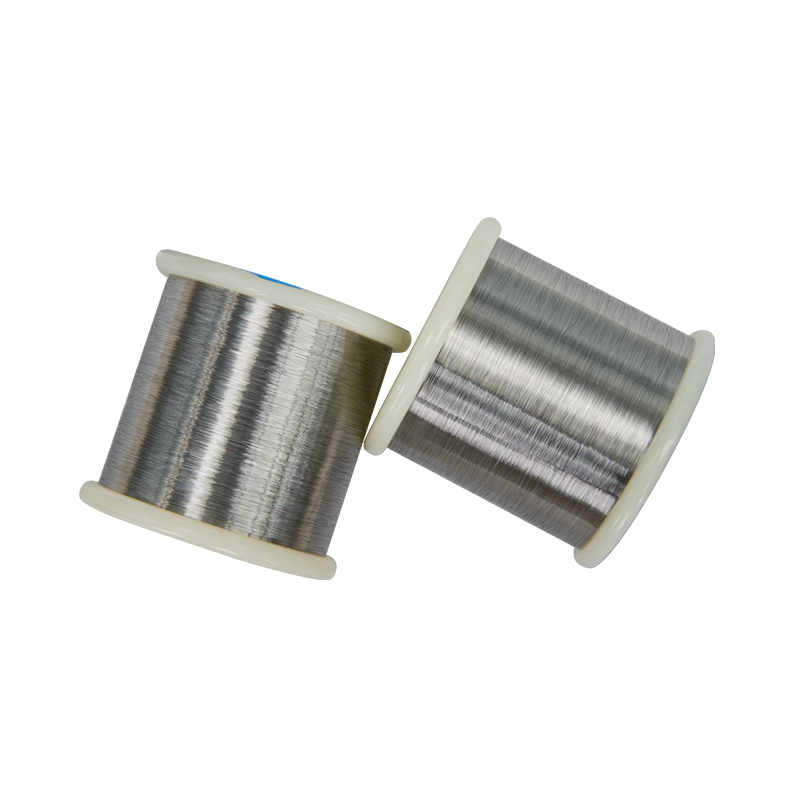

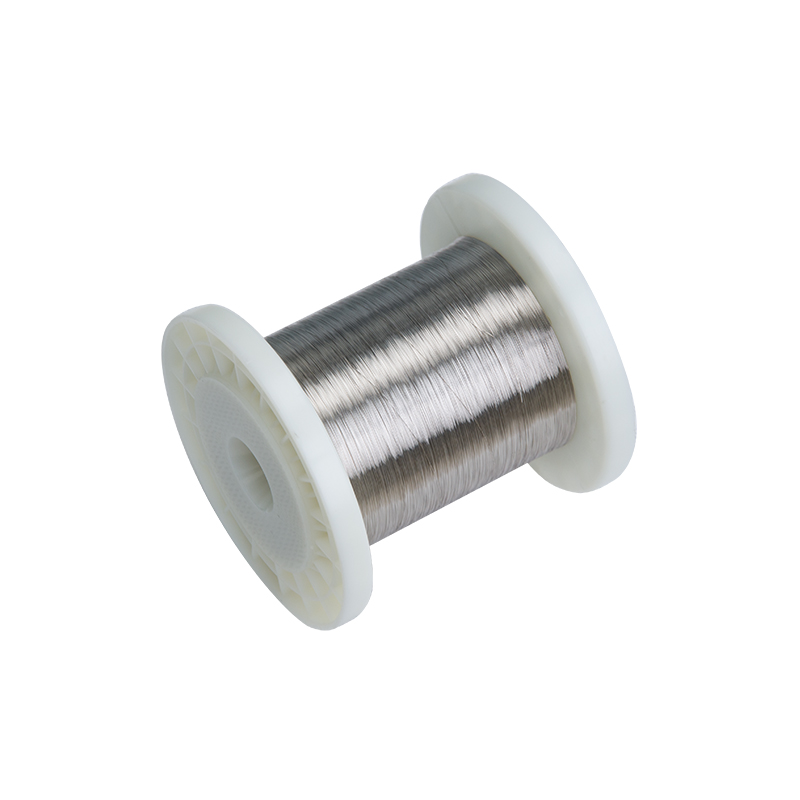

Intambo ye-AG-Cu Alloy Esekelwe Esiliva (AG72Cu28)

Izinto ezisetshenziswa njengezinto eziyinhloko zokubhoboza yi-AgCu7.5,I-AgCu25, I-AgCu28, I-AgCu55, njll., kanti i-AgCu28 isetshenziswa kabanzi. Zinomoya omuhle wokuhambisa, ukugeleza kwamanzi kanye nokumanzisa, futhi zisetshenziswa kabanzi embonini kagesi yokufudumeza. Ngenxa yokumelana okuphansi nomthwalo wesikhathi eside ngaphansi kokushisa okuphezulu, ifanelekela kuphela izingxenye ze-brazing ezinokushisa okusebenzayo okungaphansi kuka-400ºC.

Kusetshenziswa njengezinhlamvu zemali kanye nemihlobiso. Izinhlobo ezisetshenziswa njengezinhlamvu zemali yi-AgCu7.5, AgCu8,I-AgCu10, njll.; izinsimbi ezisetshenziswa njengemihlobiso yi-AgCu8.4, AgCu12.5, njll.

Ukwakheka okuvamile%

| Ag | Cu | Sn | Ni | Pb | Fe | Sb | Bi | |

| I-AgCu4 | 96+/-0.3 | 4+0.3/-0.5 | ≤0.005 | ≤0.05 | ≤0.002 | ≤0.002 | ||

| I-AgCu5 | 95+/-0.3 | 5+0.3/-0.5 | ≤0.005 | ≤0.05 | ≤0.002 | ≤0.002 | ||

| I-AgCu7.5 | 92.5+/-0.3 | 7.5+0.3/-0.5 | ≤0.005 | ≤0.1 | ≤0.002 | ≤0.002 | ||

| I-AgCu8.4 | 91.6+/-0.3 | 8.4+/-0.5 | ≤0.005 | ≤0.1 | ≤0.002 | ≤0.002 | ||

| I-AgCu10 | 90+/-0.3 | 10+/-0.5 | ≤0.005 | ≤0.2 | ≤0.002 | ≤0.002 | ||

| I-AgCu12.5 | 87.5+/-0.3 | 12.5+/-0.5 | ≤0.005 | ≤0.2 | ≤0.002 | ≤0.002 | ||

| I-AgCu20 | 80+/-0.3 | 20+/-0.5 | ≤0.005 | ≤0.2 | ≤0.002 | ≤0.002 | ||

| I-AgCu23 | 77+/-0.5 | 23+/-0.5 | ≤0.005 | ≤0.2 | ≤0.002 | ≤0.002 | ||

| I-AgCu25 | 75+/-0.5 | 25+/-0.5 | ≤0.005 | ≤0.2 | ≤0.002 | ≤0.002 | ||

| I-AgCu26 | 74+/-0.5 | 26+/-0.5 | ≤0.005 | ≤0.2 | ≤0.002 | ≤0.002 | ||

| I-AgCu28 | 72+/-0.5 | 28+/-0.5 | ≤0.005 | ≤0.2 | ≤0.002 | ≤0.002 | ||

| I-AgCu50 | 50+/-0.5 | 50+/-0.5 | ≤0.005 | ≤0.25 | ≤0.002 | ≤0.002 | ||

| I-AgCu99 | 1+/-0.2 | 99+0.2/-0.5 | ||||||

| I-AgCu18Ni2 | 80+/-0.5 | 18+/-0.5 | / | 2+/-0.3 |

Bhala umlayezo wakho lapha bese uwuthumela kithi

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu