intambo ye-alloy ethambile ye-magnetic annealed Ni80Mo5 PERMALLOY 80/MU/80/1J79,

Isetshenziswa kakhulu ezindaweni ezimbili zokuguqulwa kwamandla kanye nokucubungula ulwazi

Embonini yamandla, ikakhulukazi ensimini yamagnetic ephezulu, i-alloy inamandla aphezulu okungenisa amandla kanye nokulahlekelwa okuphansi kwe-alloy. Embonini ye-elekthronikhi, ikakhulukazi e-alloy ephansi noma ephakathi nendawo enokuvuleka kwamandla aphezulu okusebenzisa amandla kanye namandla aphansi okuphoqelela. Emazameni aphezulu, kufanele kwenziwe ngomugqa omncane noma i-alloy, ukumelana okuphezulu. Ngokuvamile ngeshidi noma umugqa.

Izinto ezithambile zikamazibuthe ezishintshaniswa nokusetshenziswa, ngenxa yemisinga ye-eddy eshintshanayo ebangelwa ngaphakathi kwezinto, okuholela ekulahlekelweni, lapho ukumelana kwe-alloy kuncane, ukujiya kukhulu, imvamisa yensimu kamazibuthe eshintshanayo iphakama, ukulahlekelwa kwamanje kwe-eddy kukhulu, amandla kazibuthe ancipha kakhulu. Ngenxa yalokhu, izinto kumele zenziwe ishidi elincane (iteyipu), kanye nomphezulu ombozwe ngesendlalelo sokuvikela, noma ukusetshenziswa kwezindlela ezithile ebusweni ukwakha isendlalelo sokuvikela i-oxide, ama-alloy anjalo avame ukusetshenziswa nge-magnesium oxide electrophoresis coating.

I-iron-nickel alloy isetshenziswa kakhulu emkhakheni wamagnetic oshintshashintshayo, ikakhulukazi i-yoga iron, i-relay, ama-Small Power Transformers kanye ne-Magnetically shield.

I-Permalloyukuvikela ngemagnethi okufanele ukwenze: Ukuze uvimbele ukuphazamiseka kwensimu yamagnetic yangaphandle, ngokuvamile ku-CRT, ingxenye yokugxila kwe-electron beam yangaphandle ye-CRT kanye nesivikelo semagnethi, ungadlala indima yokuvikela ngemagnethi.

| ukwakheka | C | P | S | Mn | Si |

| ≤ | |||||

| Okuqukethwe(%) | 0.03 | 0.02 | 0.02 | 0.3~0.6 | 0.15~0.3 |

| ukwakheka | Ni | Cr | Mo | Cu | Fe |

| Okuqukethwe(%) | 79.0~81.0 | - | 4.8~5.2 | ≤0.2 | I-Bal |

Uhlelo lokwelapha ukushisa

| uphawu lwesitolo | I-Annealing medium | izinga lokushisa lokushisa | Gcina isikhathi sokushisa/h | Izinga lokupholisa |

| 1j85 | I-hydrogen eyomile noma i-vacuum, ingcindezi ayidluli ku-0.1 Pa | Kanye nokushisa kwesithando somlilo ku-1100~1150ºC | 3~6 | Ku-100 ~ 200 ºC / h, ukupholisa ngesivinini kufike ku-600 ºC, kusheshe kufike ku-300 ºC kudonswe ishaja |

Izigaba zemikhiqizo

-

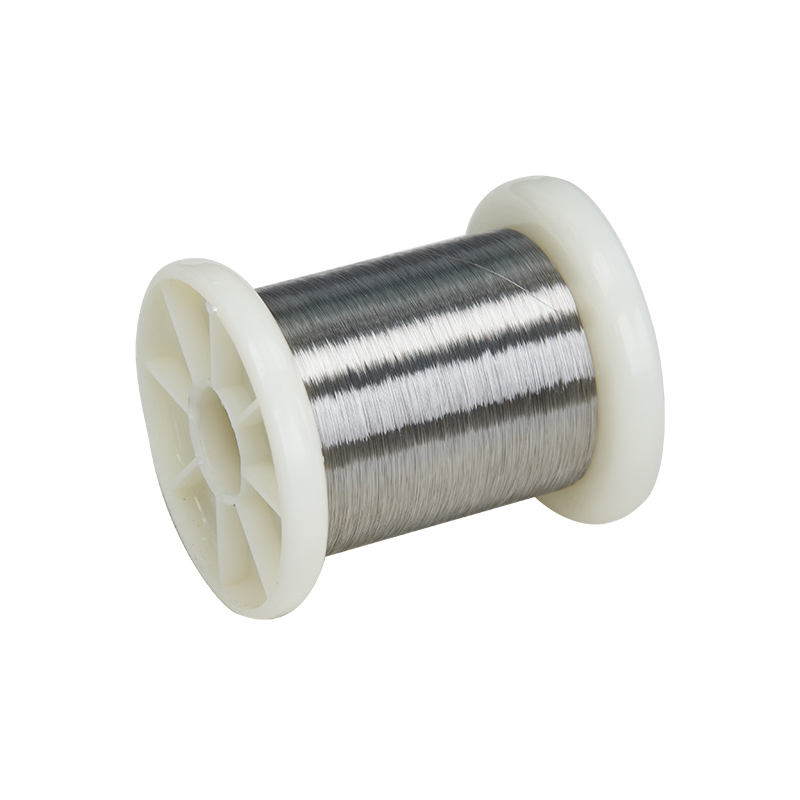

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu