Izinto zokushisa ze-thermofin ezenziwe ngokwezifiso zeTankii Izinto zokushisa ezihlanganisiwe nge-bayonet kagesi Izinto zokushisa ze-bayonet

Incazelo Yomkhiqizo

Ukuze sihlangabezane nezidingo eziqondile zamakhasimende abalulekile, sigxile ekuhlinzekeni uhla olukhethekile lweIzinto Zokushisa Zohlobo Lwe-bayonetkumakhasimende ethu ahlonishwayo. Umkhiqizo onikezwayo unikezwa amakhasimende ethu adumile ngokucabangela imikhawulo yesabelomali sabo kanye nezidingo eziqondile. Ngaphezu kwalokhu, sinikeza le mikhiqizo ngemuva kokuyidlulisa uchungechunge lokuhlolwa kwekhwalithi ngaphansi kokuqondisa okuqinile kwabalawuli bekhwalithi abanekhono, ukuze siqinisekise ukungabi naphutha kanye nekhwalithi yayo.

Iisici sokushisaIphakheji yokushintsha i-/radiant tube iqukethe izinto zokushisa ze-Custom Electric bayonet kanye nama-radiant tube e-kanthal APM alloy. Izinto zokushisa ze-bayonent zizothatha indawo yemishini yokuqala kunoma yisiphi isithando sikagesi futhi ziphathe izilinganiso zamandla ezifika ku-70kw ngesici ngasinye. Izinto zenziwe nge-Ni/Cr noma i-Kanthal APM alloy yokushisa okuphezulu ukuze ivumelane namazinga okushisa okusebenza kwesithando kusukela ku-200 kuya ku-22. 50 ℉(95 kuya ku-1230℃).

50 ℉(95 kuya ku-1230℃).

| ISAKHIWO I-OD (ngaphakathi) (I-NiCr ALLOY) | Ama-Kilowatts Aphezulu/Unyawo Oluqondile | ISAKHIWO I-OD (ngaphakathi) (I-FeCrAl ALLOY) | ||||

| KUFIKA KU-1000°F | 1000°F Kuya ku-1350°F | 1350°F Kuya ku-1700°F | 1700°F KUYA KU-2050°F | 2050°F KUYA KU-2250°F | ||

| 2 3/4 | 2.38 | 2.20 | 1.88 | 1.56 | ||

| 2.28 | 2.10 | 1.87 | 2 5/8 | |||

| 3 3/8 | 3.80 | 3.47 | 2.96 | 2.44 | ||

| 3.83 | 3.48 | 3.12 | 3 1/8 | |||

| 3 3/4 | 4.57 | 4.14 | 3.48 | 2.94 | ||

| 3.83 | 3.48 | 3.12 | 4 5/16 | |||

| 4 3/4 | 6.46 | 5.83 | 4.99 | 4.14 | ||

| 3.83 | 5.40 | 4.90 | 4 7/8 | |||

| 5 3/4 | 7.26 | 6.59 | 5.68 | 4.68 | ||

| 6.43 | 5.84 | 5.28 | 6 | |||

| 6 1/8 | 8.12 | 7.36 | 6.32 | 5.27 | ||

| 7.28 | 6.60 | 6.00 | 6 3/4 | |||

| 7 3/4 | 9.76 | 8.86 | 7.62 | 6.36 | ||

Izigaba zemikhiqizo

-

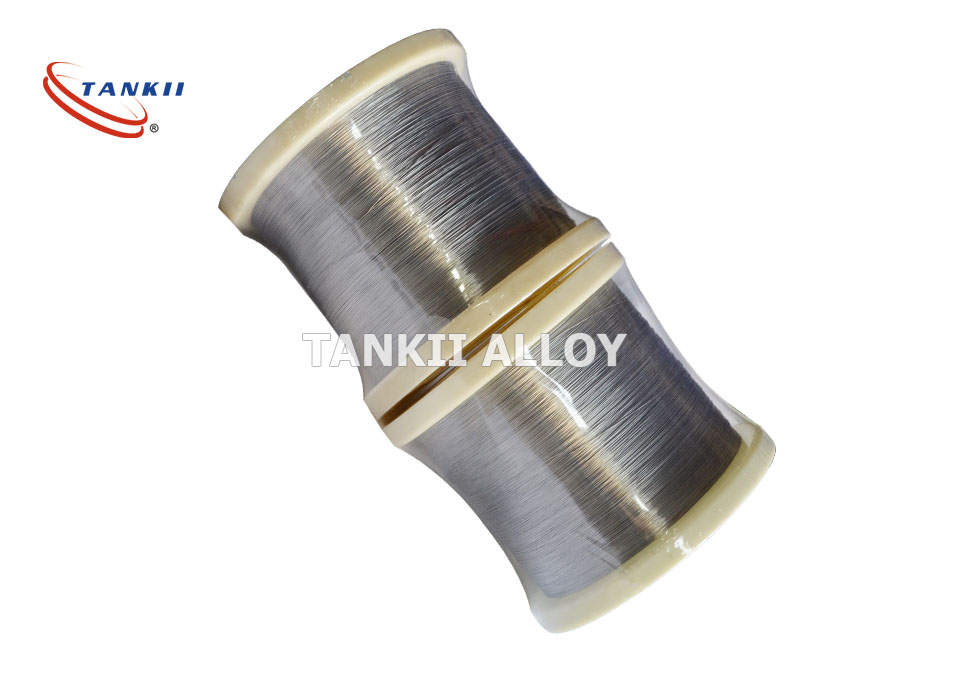

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu