Siyakwamukela kumawebhusayithi ethu!

I-Tankii J-Type Thermocouple Bare Wire SWG30/SWG25/SWG19 Ukuzwela Okuphezulu Kokushisa

Incazelo Yomkhiqizo

Uhlobo J Thermocouple Bare Wire (SWG30/SWG25/SWG19)

Ukubuka Konke Komkhiqizo

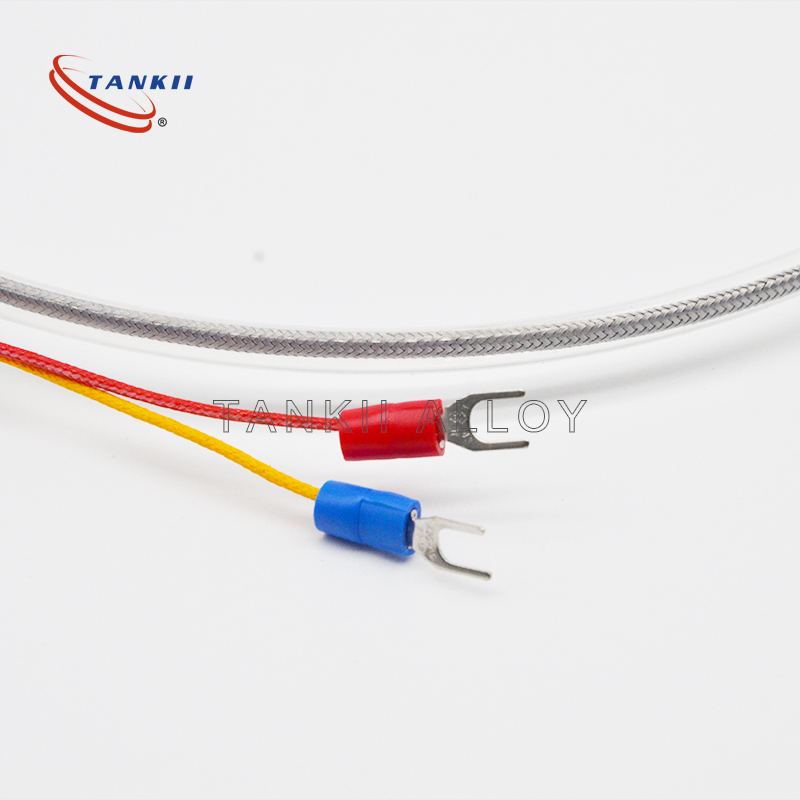

Intambo engenalutho ye-Type J thermocouple, into eqonda izinga lokushisa ngokunemba okuphezulu eyenziwe yi-Tankii Alloy Material, iqukethe ama-conductor amabili e-alloy ahlukene—i-iron (positive leg) kanye ne-constantan (i-copper-nickel alloy, negative leg)—eyenzelwe ukulinganisa izinga lokushisa ngokunembile ezindaweni ezishisa kahle. Itholakala kuma-gauge amathathu entambo ajwayelekile: i-SWG30 (0.305mm), i-SWG25 (0.51mm), kanye ne-SWG19 (1.02mm), le ntambo engenalutho iqeda ukuphazamiseka kokushisa, okwenza kube kuhle kakhulu ekuhlanganisweni kwe-thermocouple ngokwezifiso, ukulinganiswa kwezinga lokushisa eliphezulu, kanye nezinhlelo zokusebenza ezidinga ukuxhumana ngqo nemidiya elinganisiwe. Isebenzisa ubuchwepheshe be-Huona bokuncibilikisa nokudweba i-alloy ethuthukisiwe, i-gauge ngayinye igcina ukubekezelelana okuqinile kobukhulu kanye nezakhiwo ze-thermoelectric ezizinzile, iqinisekisa ukuhambisana phakathi kwama-batches.

Izikhundla Ezijwayelekile

- Uhlobo lwe-Thermocouple: J (Iron-Constantan)

- Amageyiji Ocingo: SWG30 (0.315mm), SWG25 (0.56mm), SWG19 (1.024mm)

- Izindinganiso Zamazwe Ngamazwe: Zihambisana ne-IEC 60584-1, ASTM E230, kanye ne-GB/T 4990

- Ifomu: Ucingo olungenalutho (olungafakwanga umswakama, ukuze lufakwe umswakama/uvikele ngokwezifiso)

- Umkhiqizi: Izinto Zokwenziwa Ze-Tankii Alloy, eziqinisekiswe yi-ISO 9001 futhi ezilinganiswe ngokwezindinganiso zokushisa zikazwelonke

Izinzuzo Eziyinhloko (uma kuqhathaniswa nezintambo zohlobo lwe-J ezifakwe i-insulation kanye nezinye izinhlobo ze-thermocouple)

Lesi sixazululo sentambo engenalutho sivelele ngokuguquguquka kwaso, ukunemba, kanye nokuzivumelanisa nezimo ngokwesilinganiso:

- Ukusebenza Okulinganiselwe Nge-Gauge: I-SWG30 (i-gauge encane) inikeza ukuguquguquka okuphezulu kokufakwa kwesikhala esiqinile (isb., izinzwa ezincane); i-SWG19 (i-gauge ebanzi) inikeza amandla athuthukisiwe okusebenza ezindaweni zezimboni; i-SWG25 ilinganisela ukuguquguquka nokuqina kokusetshenziswa okujwayelekile.

- Ukunemba Okuphakeme Kwe-Thermoelectric: Kukhiqiza amandla aqinile e-electromotive (EMF) anokuzwela okungu-~52 μV/°C (ku-200°C), okusebenza kahle kakhulu kuhlobo K ebangeni lika-0-500°C, ngokunemba kweKlasi 1 (ukubekezelela: ±1.5°C noma ±0.25% wokufunda, noma yikuphi okukhulu).

- Ukuguquguquka Kwezintambo Ezingenalutho: Akukho ukufakelwa kokuvikela okufakwe ngaphambilini okuvumela abasebenzisi ukuthi benze ngokwezifiso ukuvikelwa (isb., amashubhu e-ceramic, ukugoba kwe-fiberglass) ngokusekelwe ezidingweni ezithile zokushisa/ukugqwala, ukunciphisa imfucuza evela ezintanjeni ezifakwe ukufudumala ezingalingani.

- Izindleko Ezisebenzayo: I-iron-constantan alloy ishibhile kakhulu kune-thermocouples yensimbi eyigugu (Izinhlobo R/S/B) ngenkathi inikeza ukuzwela okuphezulu kunohlobo K, okwenza kube kuhle kakhulu ekulinganisweni kwezinga lokushisa eliphakathi nendawo (0-750°C) ngaphandle kokusebenzisa imali eningi ngokweqile.

- Ukumelana Okuhle Nokubola: Isebenza ngokuthembeka ezindaweni ezibola kuze kufike ku-750°C; umqhubi wensimbi wakha ungqimba lwe-oxide oluvikelayo olunciphisa ukukhukhuleka, olwelula impilo yenkonzo uma kuqhathaniswa nezintambo zensimbi ezingaxutshiwe.

Imininingwane Yobuchwepheshe

| Isici | SWG30 (0.315mm) | SWG25 (0.56mm) | SWG19 (1.024mm) |

|---|---|---|---|

| Izinto Zomqhubi | Okuhle: Insimbi; Okubi: I-Constantan (Cu-Ni 40%) | Okuhle: Insimbi; Okubi: I-Constantan (Cu-Ni 40%) | Okuhle: Insimbi; Okubi: I-Constantan (Cu-Ni 40%) |

| Ububanzi obujwayelekile | 0.305mm | 0.51mm | 1.02mm |

| Ukubekezelelana kobubanzi | ± 0.01mm | ± 0.015mm | ± 0.02mm |

| Ibanga Lokushisa | Okuqhubekayo: 0-700°C; Isikhathi esifushane: 750°C | Okuqhubekayo: 0-750°C; Isikhathi esifushane: 800°C | Okuqhubekayo: 0-750°C; Isikhathi esifushane: 800°C |

| I-EMF ku-100°C (uma kuqhathaniswa no-0°C) | 5.268 mV | 5.268 mV | 5.268 mV |

| I-EMF ku-750°C (uma kuqhathaniswa no-0°C) | 42.919 mV | 42.919 mV | 42.919 mV |

| Ukumelana Nomqhubi (20°C) | ≤160 Ω/km | ≤50 Ω/km | ≤15 Ω/km |

| Amandla Okudonsa (20°C) | ≥380 MPa | ≥400 MPa | ≥420 MPa |

| Ukwelulwa (20°C) | ≥20% | ≥22% | ≥25% |

Imininingwane Yomkhiqizo

| Into | Imininingwane |

|---|---|

| Ukuqedwa Komphezulu | I-annealed ekhanyayo (engenayo i-oxide, i-Ra ≤0.2μm) |

| Ifomu Lokunikeza | Ama-spool (ubude: 50m/100m/300m ngegeji ngayinye) |

| Ukuhlanzeka Kwamakhemikhali | Insimbi: ≥99.5%; I-Constantan: Cu 59-61%, Ni 39-41%, ukungcola ≤0.5% |

| Ukulinganisa | Kulandelelwa ku-NIST/China National Institute of Metrology (CNIM) |

| Ukupakisha | Ivalwe nge-vacuum ezikhwameni ezigcwele i-argon (ukuvimbela ukushiswa); ama-spool epulasitiki emabhokisini angangenisi umswakama |

| Ukwenza ngokwezifiso | Ukunqunywa ngobude (ubuncane obungu-1m), ubumsulwa obukhethekile be-alloy (insimbi emsulwa kakhulu yokulinganisa), noma iziphetho ezifakwe emathinini kusengaphambili |

Izicelo Ezijwayelekile

- Ukuhlanganiswa Kwe-Thermocouple Eyenziwe Ngokwezifiso: Kusetshenziswa abakhiqizi bezinzwa ukwakha ama-probe anokuvikelwa okuqondene nohlelo lokusebenza (isb., ama-probe anezigxobo ze-ceramic zama-oven, ama-probe anezigxobo zensimbi engagqwali zama-liquid).

- Ukuzwa Izinga Lokushisa Lezimboni: Ukulinganisa okuqondile ekucubungulweni kokudla (ukubhaka kuhhavini, 100-300°C) kanye nokubumba kwepulasitiki (izinga lokushisa lokuncibilika, 200-400°C)—I-SWG25 ikhethwa ngokulinganisela kokuguquguquka namandla.

- Imishini Yokulinganisa: Izinto ezibhekisela kuma-calibrators okushisa (SWG30 yamaseli okulinganisa amancane).

- Ukuhlolwa Kwezimoto: Ukuqapha amazinga okushisa enjini kanye nesistimu yokukhipha umoya (SWG19 yokumelana nokudlidliza).

- Ucwaningo Lwelabhorethri: Ukuhlolwa kwephrofayili yokushisa ekuhlolweni kwesayensi yezinto ezibonakalayo (0-700°C) lapho kudingeka khona ukufakelwa okwenziwe ngokwezifiso.

Izinto ze-Tankii Alloy zibeka yonke inqwaba yezintambo ezingenalutho zohlobo lwe-J ngaphansi kokuhlolwa kwekhwalithi okuqinile: ukuhlolwa kokuqina kwe-thermoelectric (imijikelezo eyi-100 ye-0-750°C), ukuhlolwa kobukhulu (i-laser micrometry), kanye nokuhlaziywa kokwakheka kwamakhemikhali (i-XRF). Amasampula wamahhala (1m ngegeji ngayinye) kanye nezitifiketi zokulinganisa ziyatholakala uma kuceliwe. Ithimba lethu lobuchwepheshe linikeza isiqondiso esiklanyelwe wena—kufaka phakathi ukukhethwa kwegeji yezinhlelo zokusebenza ezithile kanye nemikhuba emihle kakhulu yokugoqa/ukushisela—ukuqinisekisa ukusebenza kahle kakhulu ekusethweni kwe-thermocouple ngokwezifiso.

Bhala umlayezo wakho lapha bese uwuthumela kithi

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu