Siyakwamukela kumawebhusayithi ethu!

Inzwa ye-Tankii S-Type Thermocouple Sensor Ukulinganisa Okuphezulu Kwezimboni Nokuzwela Okunembile

Incazelo Yomkhiqizo

Inzwa ye-Thermocouple yohlobo lwe-S (0-1300℃, Ubude obungu-250mm)

Ukubuka Konke Komkhiqizo

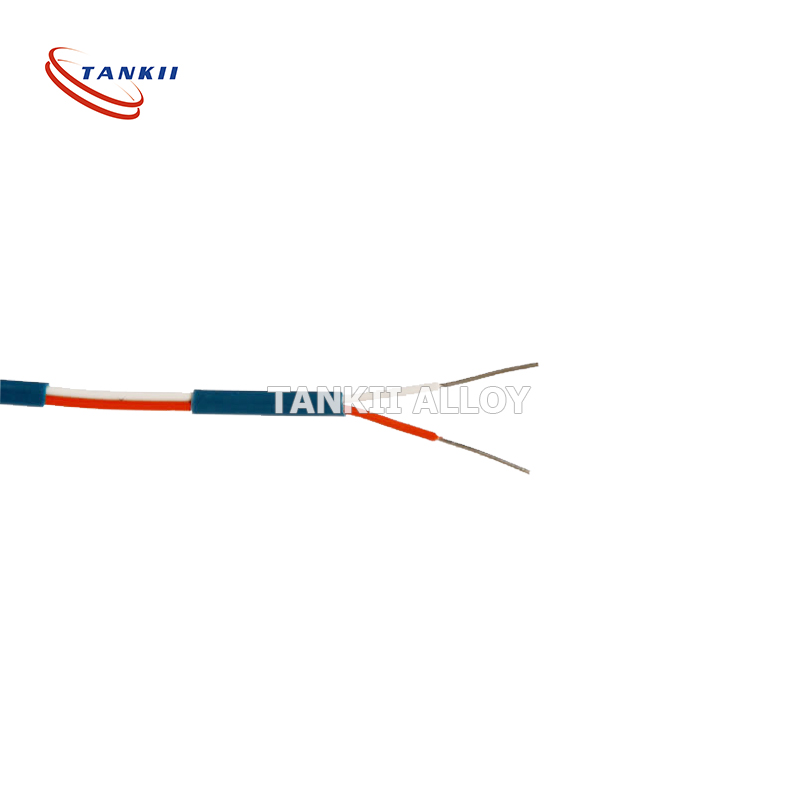

Inzwa ye-thermocouple yohlobo lwe-S (iplatinum-rhodium 10%-platinum, Pt10Rh/Pt) evela ku-Tankii Alloy Material iyingxenye yokulinganisa izinga lokushisa eliphezulu enembile kakhulu eyenzelwe izindawo ezishisayo kakhulu. Ngomklamo olungiselelwe wena ongama-250mm ubude obuphelele, ishubhu lokuvikela i-ceramic elingaphandle elingu-7-8mm ububanzi, kanye nentambo yomqhubi wobubanzi obungu-0.2mm, le sensor ifinyelela ukutholwa okunembile kwezinga lokushisa ku-0-1300℃ ngomphumela we-Seebeck wezinsimbi zensimbi ezinhle. Ihlanganisaukuzinza okuhle kakhulu kokushisa okuphezulu,ukuzulazula okuphansi kokulinganisa, futhiukuqina kwesakhiwo okuqinile—okwenza kube ukukhetha okuthandwayo kwezinqubo zokushisa okuphezulu njengokuqapha izinga lokushisa kwesitofu sezimboni, ukuhlolwa kokushisa kokwelashwa kokushisa, kanye nokuhlolwa kokuthembeka kokushisa okuphezulu kwezingxenye ze-elekthronikhi.

Izikhundla Ezijwayelekile kanye Nesisekelo Sesakhiwo

- Ibanga Lenzwa: Uhlobo lwe-S (IEC 60584-1 Class 1; olulingana ne-ANSI/ASTM E230 Uhlobo S) – i-thermocouple yensimbi enhle ene-Pt10Rh (i-electrode enhle) kanye nabaqhubi be-Pt (i-electrode engemihle) abahlanzekile

- Imininingwane Eyinhloko: Ibanga lokushisa 0-1300℃ (ukusetshenziswa kwesikhashana kufika ku-1400℃ imizuzu engu-≤30); ubude obuphelele 250mm (ubude bokuphela obulinganiswayo 50mm, ubude bentambo yomthofu 200mm); ithubhu yokuvikela i-ceramic ububanzi bangaphandle 7-8mm (ubukhulu bodonga 1.2-1.5mm); ububanzi bentambo yomqhubi 0.2mm (ukubekezelelana ±0.01mm)

- Izindinganiso Ezihambisanayo: IEC 60584-1 (isigaba sokunemba kwe-thermocouple), GB/T 1672-1997 (ama-thermocouple e-platinum-rhodium), ASTM E230-19 (isimiso sama-thermocouple ensimbi enhle)

- Umkhiqizi: Izinto ze-Tankii Alloy, eziqinisekiswe yi-ISO 9001 kanye ne-ISO 14001, ezinekhono lokuncibilikisa i-alloy yensimbi enhle ngaphakathi kanye namakhono okulinganisa inzwa

Izinzuzo Eziyinhloko Eziyinhloko (Ezenzelwe i-0-1300℃ kanye Nemininingwane Yesakhiwo)

1. Ukulinganisa Ukushisa Okuphezulu Ngokunembile Nokuzinza

Isebenzisa ucingo lomqhubi we-Pt10Rh/Pt oluhlanzekile kakhulu oluyi-99.99% (ububanzi obungu-0.2mm) olunokwakheka okufanayo kwe-alloy—ukunemba kokulinganisa kufinyelela ku-Class 1 (iphutha ≤±1.5℃ ku-0-600℃, ≤±0.25% t ku-600-1300℃, t=izinga lokushisa elilinganisiwe). Ngemva kwamahora ayi-1000 okusebenza okuqhubekayo ku-1200℃, i-thermoelectric potential drift i-<3μV (ilingana nephutha lokushisa <0.4℃)—ingcono kakhulu kune-K-type thermocouples (drift >10μV ku-800℃) futhi ifaneleka ukuqapha izinga lokushisa eliphakeme isikhathi eside.

2. Ukuqina Kwesakhiwo Okulungiselelwe

- Ishubhu Lokuvikela Lobumba: I-ceramic ephezulu ye-alumina engu-7-8mm ububanzi bangaphandle (okuqukethwe kwe-Al₂O₃ ≥95%) enokumelana nokushisa okuphezulu okufika ku-1600℃, amandla okucindezela ≥150MPa—ihlukanisa ngempumelelo insimbi encibilikisiwe, uthuli lwesithando, kanye namagesi agqwalisayo ngenkathi iqinisekisa ukusebenza kahle kokudlulisa ukushisa (ukuqhuba ukushisa ≥20 W/(m·K) ku-800℃).

- Umklamo Womqhubi Nokuxhumanisa: Umqhubi wobubanzi obungu-0.2mm ulinganisela ukuguquguquka kanye namandla okushisa okuphezulu (amandla okudonsa ≥350MPa ku-25℃, ≥150MPa ku-1300℃); ingxenye yokulinganisa isebenzisa ukushisela kwamabala (ububanzi bendawo yokushisela 0.3-0.4mm) ukuqinisekisa ukuphuma kwamandla okushisa okuzinzile ngaphandle kokumelana nokuxhumana.

- Ukuqhathaniswa Kobude Obuphelele: Ubude obuphelele obungu-250mm (isiphetho sokulinganisa esingu-50mm + ucingo lwe-lead olungu-200mm) lulungiselelwe ukufakwa kodonga oluseceleni lwesithando sezimboni—lugwema ukugoba ngokweqile ucingo lwe-lead ngenkathi luqinisekisa ukuthi isiphetho sokulinganisa sifinyelela endaweni yokushisa eyinhloko.

3. Ukuthembeka Okuguquliwe Kwesicelo

Inzwa inokumelana okuhle kwe-oxidation (yakha ifilimu yokuvikela ye-PtO₂ ebanzi ekushiseni okuphezulu) kanye nokumelana nokushaqeka kokushisa (ingamelana nokushintsha kwezinga lokushisa elingu-500℃/min ngaphandle kokuqhekeka kweshubhu le-ceramic). Intambo yokudonsa isebenzisa ukufakelwa kwe-Teflon ekushiseni okuphezulu (izinga lokushisa lokusebenza -60℃ kuya ku-260℃) ukuvimbela amasekethe amafushane ezindaweni zokusebenzela ezishisa kakhulu, futhi i-terminal ifakwe isixhumi esijwayelekile se-M12 sokuxhuma okusheshayo kuma-transmitter okushisa.

Imininingwane Yobuchwepheshe

| Isici | Inani (Elijwayelekile) | Ukubaluleka Kohlelo Lokusebenza |

|---|---|---|

| Uhlobo lwenzwa | Uhlobo lwe-S (Pt10Rh/Pt) | Insimbi enhle emsulwa kakhulu iqinisekisa ukuzinza kokushisa okuphezulu |

| Ibanga Lokushisa | 0-1300℃ (okuqhubekayo); 0-1400℃ (isikhathi esifushane ≤30min) | Ihlanganisa izinqubo eziningi zokushisa okuphezulu kwezimboni |

| Ukunemba Kokulinganisa | Isigaba 1: ±1.5℃ (0-600℃); ±0.25% t (600-1300℃) | Ihlangabezana nezidingo zokwelashwa kokushisa okunembile (isb., ukucima izingxenye zezimoto) |

| Ubude obuphelele | 250mm (Okwenziwe Ngokwezifiso) | Kwenzelwe ukufakwa kodonga oluseceleni kwesithando somlilo |

| Ukucaciswa kweThubhu le-Ceramic | Ububanzi bangaphandle 7-8mm | Ukuvikela okulinganiselayo kanye nokusebenza kahle kokudlulisa ukushisa |

| Ububanzi bentambo yomqhubi | 0.2mm (ukubekezelelana ± 0.01mm) | Iqinisekisa ukuzinza kwamandla kagesi kanye nokuguquguquka |

| Amandla Okushisa Ngogesi (1000℃) | 10.591mV (uma kuqhathaniswa ne-0℃ reference junction) | Ihambisana namanani okulinganisa ajwayelekile e-IEC 60584-1 |

| Isikhathi Sokuphendula (τ₅₀) | ≤2s (emoyeni ku-800℃) | Ivumelana nezinguquko zokushisa ezishintshashintshayo ekwelashweni kokushisa |

| Impilo Yesevisi (1200℃ okuqhubekayo) | Amahora angu-≥1000 | Kunciphisa imvamisa yokugcinwa kwezitofu zezimboni |

Imininingwane Yomkhiqizo

| Into | Imininingwane | Inzuzo Yokusebenza |

|---|---|---|

| Izinto Zokuvikela Ishubhu | I-ceramic ephezulu ye-alumina engu-95% | Ukumelana nokushisa okuphezulu kanye nokumelana nokugqwala |

| Ukufakwa Komshini Wokucindezela | Ubuhlalu be-ceramic be-alumina obuhlanzekile kakhulu (isigaba esingu-250℃); i-Teflon (isigaba sokushisa kwegumbi) | Ivimbela ukujikeleza okufushane ekushiseni okuphezulu |

| Isixhumi Sesiphetho | Isixhumi esingangeni manzi se-M12 (izinga lokuvikelwa kwe-IP65) | Ukufakwa okusheshayo kanye nokuvikela uthuli/ukuvikela amanzi |

| Isitifiketi Sokulinganisa | Umbiko wokulinganisa olandelekayo we-NIST (ongakukhetha) | Ihlangabezana nezidingo zokuqinisekiswa kwe-metrology |

| Ukupakisha | I-foam engashaqeki + ibhokisi lekhadibhodi; ukupakishwa kwengxenye eyodwa | Kuvimbela ukuphuka kwepayipi le-ceramic ngesikhathi sokuhamba |

| Ukwenza ngokwezifiso | Ubude obuphelele (100-1000mm); izinto zeshubhu le-ceramic (99% alumina ye-1600℃); uhlobo lwesixhumi (isixhumi esincane samadivayisi kagesi) | Ivumelana nezidingo ezikhethekile zokufakwa kanye nezicelo |

Izimo Ezijwayelekile Zokusebenza

1. Izinqubo Zokushisa Okuphezulu Kwezimboni

Isetshenziselwa ukuqapha izinga lokushisa ezitsheni zokwelapha ukushisa zensimbi (isb., ukufakelwa kwensimbi engagqwali ku-900-1100℃) kanye nezitofu zokushisa ze-ceramic (1200-1300℃)—ishubhu le-ceramic elingu-7-8mm liyamelana nokuguguleka kothuli lwesithando, kanti ukunemba kwe-Class 1 kuqinisekisa ikhwalithi yomkhiqizo ehambisanayo.

2. Ukuhlolwa Kokuthembeka Kwezingxenye Ze-elekthronikhi

Kusetshenziswa ekuhlolweni kokuguga okushisa okuphezulu kwama-semiconductor chips nama-power modules (0-1200℃)—i-conductor encane engu-0.2mm kanye nesikhathi sokuphendula okusheshayo (≤2s) ibamba ngokunembile izinguquko zokushisa zesikhashana ngesikhathi sokushisa kwengxenye, ihlinzeka ngokusekelwa kwedatha kokuhlolwa kokuthembeka.

3. Ukulinganiswa Kwezinzwa Zokucindezela Eziphezulu

Njengereferensi yokushisa ezinhlelweni zokulinganisa izinga lokushisa eliphezulu lenzwa yokucindezela (isb., ukulinganisa izinzwa zokucindezela injini yezimoto ku-800-1000℃)—ukukhishwa kwamandla okushisa okuzinzile kuqinisekisa ukunemba kokulinganisa kwezinzwa zokucindezela.

4. Ucwaningo Lwelabhorethri Oluphezulu Lokushisa

Isetshenziswa emalabhorethri esayensi yezinto ezibonakalayo ekuhlolweni kokushintsha kwesigaba sokushisa okuphezulu (0-1300℃)—ubude obungu-250mm bufanelekela izitofu ezibekwe phezulu, futhi ukulinganiswa kwe-NIST okungakhethwa kuhlangabezana nezidingo zokulandelela idatha yocwaningo.

Ukuqinisekiswa Kwekhwalithi Nokusekelwa Kobuchwepheshe

I-Tankii Alloy Material isebenzisa ukulawulwa kwekhwalithi kwezigaba ezintathu kwezinzwa ze-thermocouple zohlobo lwe-S:

- Ukuhlolwa Komqhubi: Ukuhlaziywa kokwakheka kwe-alloy ye-XRF (kuqinisekisa okuqukethwe kwe-Pt10Rh okungu-9.5-10.5%) kanye nokuhlolwa kokumelana ne-probe yamaphuzu amane (kuqinisekisa ubumsulwa).

- Ukuhlolwa Kokuhlanganiswa: Ukulinganiswa kokushisa okuphezulu esithandweni somlilo esinembile (ukunemba kokushisa ±0.1℃) kanye nokuhlolwa kokushaqeka kokushisa (imijikelezo engu-50 engu-25℃-1300℃).

- Ukuqinisekiswa Kokugcina: Ukuhlolwa kokusebenza okuqhubekayo kwamahora angama-24 ku-1200℃ ukuqinisekisa ukusebenza kokukhukhuleka kanye nokuhlolwa kokungena kwamanzi kwesixhumi (IP65).

Amasampula wamahhala (nombiko wokulinganisa) kanye nesiqondiso sokufakwa endaweni kuyatholakala uma ucela. Ithimba lethu lobuchwepheshe linikeza izixazululo ezenziwe ngokwezifiso njengokulungiswa kobude bezinzwa zezitofu ezikhethekile kanye nesiqondiso sokufanisa nama-transmitter okushisa ukuqinisekisa ukusebenza kahle kokulinganisa.

Bhala umlayezo wakho lapha bese uwuthumela kithi

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu