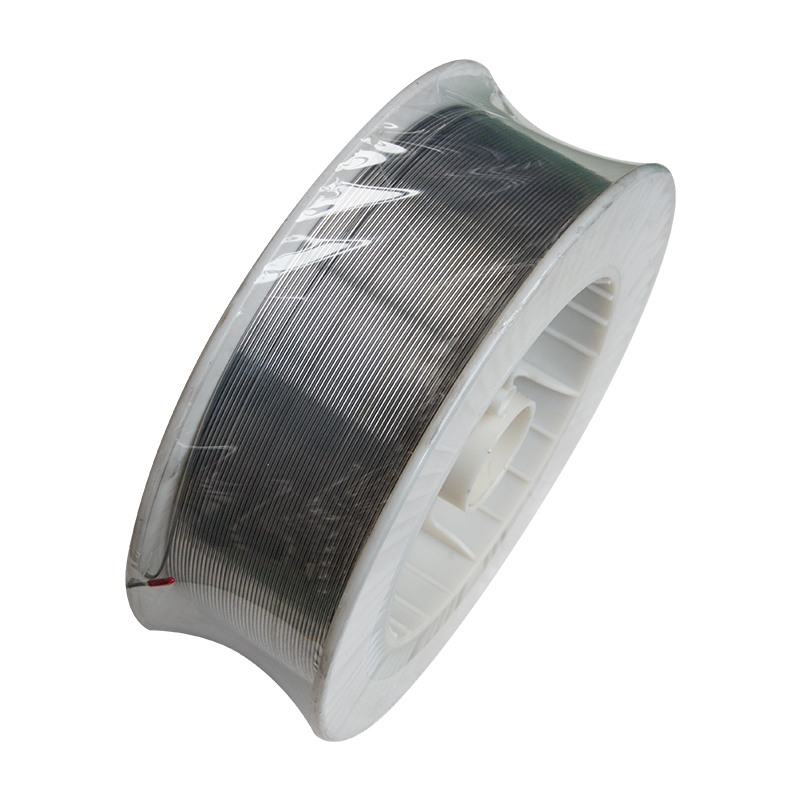

I-Vacon 12 Fe-Ni-Co Glass Sealing Alloy Wire Kovar Alloy Wire

I-Vacon 12Intambo ye-Fe-Ni-Co Glass Sealing Alloy WireI-KovarUcingo lwe-alloy

(Igama Elivamile:I-Kovar, Nilo K, I-KV-1, I-Dilver Po, Vacon 12)

Imininingwane:Ishidi/Ipuleti, Ibha/Induku/Intambo/Ikhoyili, I-Capillary/Ipayipi/Ishubhu

Ububanzi Bosayizi:

—*Ishidi_Ubukhulu 0.1mm ~ 40.0mm, ububanzi: ≤300mm, Isimo: i-cold rolled (eshisayo), ekhanyayo, ekhanyayo e-annealed

—*IsiyingiI-Wire_Dia 0.1mm ~ I-Dia 5.0mm, Isimo: idonswe ngokubandayo, ikhanya, i-annealed ekhanyayo

—*Intambo Eyisicaba_Ububanzi 0.5mm ~ Ububanzi 5.0mm, ubude: ≤1000mm, Isimo: sigoqekile, sicwebezelisiwe

—*Ibha_Ububanzi 5.0mm ~ Ububanzi 8.0mm, ubude: ≤2000mm, Isimo: sidonswe kubanda, sikhanya, sicwebezela

Ububanzi obungu-8.0mm ~ Ububanzi obungu-32.0mm, ubude: ≤2500mm, Isimo: sishisiwe, sikhanya, sicwebezela

Ububanzi obungu-32.0mm ~ Ububanzi obungu-180.0mm, ubude: ≤1300mm, Isimo: ukushisa, okuhlutshiwe, okuphendukile, okushisiwe

—*I-Capillary_OD 8.0mm~1.0mm,ID 0.1mm~8.0mm,ubude:≤2500mm,Isimo: idonswe ngokubandayo, ikhanya, i-annealed ekhanyayo

—*Ipayipi_OD 120mm~8.0mm,ID 8.0mm~129mm,ubude:≤4000mm,Isimo: idonswe ngokubandayo, ikhanya, i-annealed ekhanyayo

Isicelo:

Isetshenziswa kakhulu ezingxenyeni ze-vacuum kagesi kanye nokulawula ukukhishwa komoya, i-shock tube, i-igniting tube, i-glass magnetron, ama-transistors, i-seal plug, i-relay, i-integrated circuits lead, i-chassis, ama-bracket kanye nokunye ukuvalwa kwezindlu.

Ukwakheka okuvamile%

| Ni | 28.5~29.5 | Fe | Ibhalansi. | Co | 16.8~17.8 | Si | ≤0.3 |

| Mo | ≤0.2 | Cu | ≤0.2 | Cr | ≤0.2 | Mn | ≤0.5 |

| C | ≤0.03 | P | ≤0.02 | S | ≤0.02 |

Amandla Okudonsa, i-MPa

| Ikhodi yesimo | Isimo | Ucingo | Ukuhlubula |

| R | Ithambile | ≤585 | ≤570 |

| 1/4I | 1/4 Kanzima | 585~725 | 520~630 |

| 1/2I | 1/2 Kanzima | 655~795 | 590~700 |

| 3/4I | 3/4 Kanzima | 725~860 | 600~770 |

| I | Kunzima | ≥850 | ≥700 |

Izakhiwo Ezijwayelekile Zomzimba

| Ubuningi (g/cm3) | 8.2 |

| Ukumelana kukagesi ku-20ºC(Ωmm2/m) | 0.48 |

| Ithempelesha yokumelana ne-resistant(20ºC~100ºC)X10-5/ºC | 3.7~3.9 |

| Iphuzu le-Curie Tc/ºC | 430 |

| I-Elastic Modulus, E/ Gpa | 138 |

Isilinganiso sokunwetshwa

| θ/ºC | α1/10-6ºC-1 | θ/ºC | α1/10-6ºC-1 |

| 20~60 | 7.8 | 20~500 | 6.2 |

| 20~100 | 6.4 | 20~550 | 7.1 |

| 20~200 | 5.9 | 20~600 | 7.8 |

| 20~300 | 5.3 | 20~700 | 9.2 |

| 20~400 | 5.1 | 20~800 | 10.2 |

| 20~450 | 5.3 | 20~900 | 11.4 |

Ukuqhuba kwe-thermal

| θ/ºC | 100 | 200 | 300 | 400 | 500 |

| λ/ W/(m*ºC) | 20.6 | 21.5 | 22.7 | 23.7 | 25.4 |

| Inqubo yokwelapha ukushisa | |

| Ukuhlanza ukucindezeleka | Kushiswe kufike ku-470~540ºC bese ubamba ihora eli-1~2. Kubanda |

| ukubopha | Ku-vacuum cleaner kushiswe ku-750 ~ 900ºC |

| Isikhathi sokubamba | Imizuzu eyi-14~ihora eli-1. |

| Izinga lokupholisa | Akudluli ku-10 ºC/min epholile ku-200 ºC |

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu