Siyakwamukela kumawebhusayithi ethu!

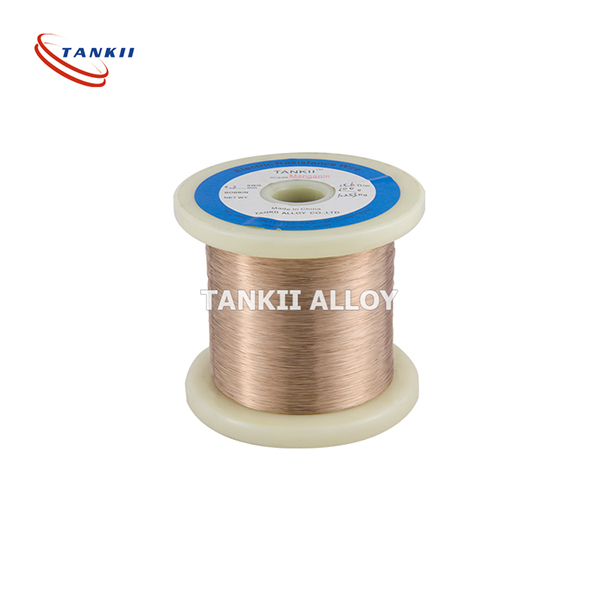

I-24AWG 36AWG Wire Resistance Manganin 6j12 ye-Precision Instrument

| Igama Lomkhiqizo | I-24AWG 36AWG Wire Resistance Manganin 6j12 ye-Precision Instrument |

| I gama le-brand | I-TANKII |

| Izinto | Ingxubevange yethusi yeManganese |

| Ubuso | Okukhanyayo |

| Okujwayelekile | I-GB/ASTM |

| I-MOQ | Isampula Yamukelwe |

Ucingo lwe-Manganese copper alloy luhlobo lwentambo oluhlanganiswe yinhlanganisela ye-manganese nethusi.

Le ngxube yaziwa ngamandla ayo aphezulu, ukuhanjiswa kukagesi okuhle kakhulu, kanye nokumelana okuhle nokugqwala. Ivame ukusetshenziswa ezinhlotsheni ezahlukene ezifana nocingo lukagesi, ukudluliselwa kwamandla, kanye nokuxhumana ngocingo. Ukwengezwa kwe-manganese ethusi kusiza ukuthuthukisa izakhiwo zemishini kanye nokusebenza kwayo konke kwentambo.

I-Cu Mn alloy iyinto esetshenziswa kabanzi yokudambisa, eyingxenye yesigaba sokuguqulwa kwe-thermoelastic martensitic. Lapho lolu hlobo lwe-alloy luphathwa ngokushisa okuguga ku-300-600 ℃, isakhiwo se-alloy siguquka sibe yisakhiwo esijwayelekile se-martensitic twin, esingazinzile kakhulu. Uma sibhekene nokucindezeleka kokudlidliza okushintshashintshayo, sizohamba ngokunyakaza kokuhlelwa kabusha, sibambe amandla amaningi futhi sibonise umphumela wokudambisa.

Izakhiwo zocingo lwe-manganin:

1. Isilinganiso sokushisa esiphansi sokumelana, 2. Ububanzi bokushisa obusetshenziswayo, 3. Ukusebenza kahle kokucubungula, 4. Ukusebenza kahle kokushisela.

Ithusi leManganese liyingxube yokumelana nokunemba, evame ukunikezwa ngesimo sentambo, ngamanani amancane amapuleti kanye nemichilo. Njengamanje, kunezinhlobo ezintathu eShayina: i-BMn3-12 (eyaziwa nangokuthi ithusi le-manganese), i-BMn40-1.5 (eyaziwa nangokuthi i-constantan), kanye ne-BMn43-0.5.

Isicelo: Kufanelekela ama-resistor anembile, ama-resistor ashelelayo, ama-transformer okuqala nokulawula, kanye nama-gauge okucindezela ukumelana ngezinjongo zokuxhumana

Bhala umlayezo wakho lapha bese uwuthumela kithi

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu