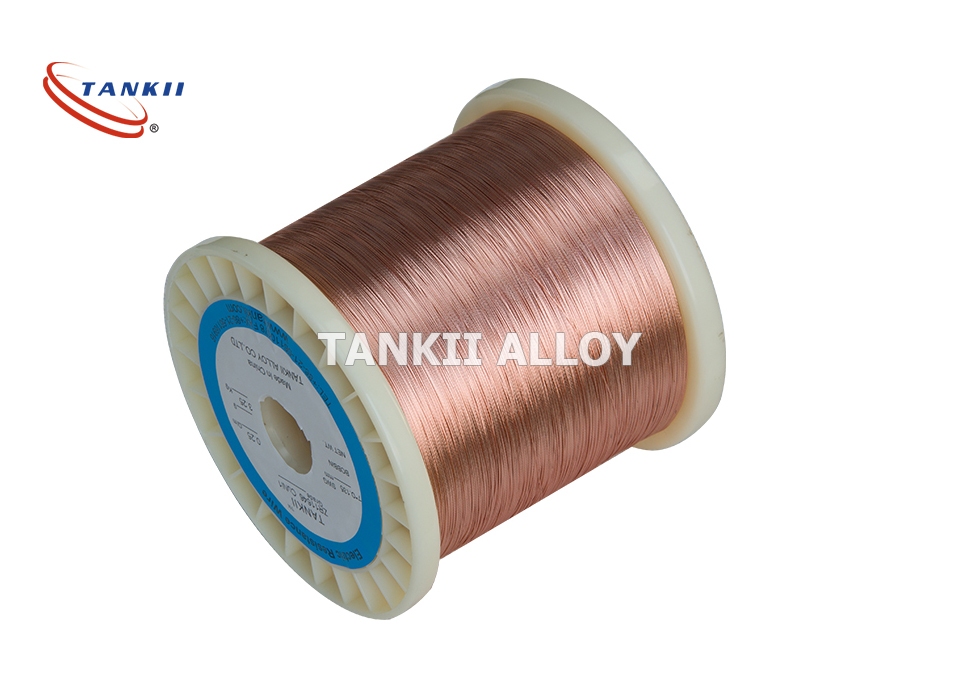

I-alloy 180 Manganin Insulated Enameled Copper Nickel CuNi Resistance Wire

I-Round Copper Based NicrI-alloy 180degree Class Insulated Copper Wire

1.Incazelo Yezinto Ezivamile

1)

Manganiningxubevange yethusi engu-84%, i-manganese engu-12%, ne-nickel engu-4%.

I-Manganin wire kanye ne-foil kusetshenziswa ekukhiqizeni izinto eziphikisayo, ikakhulukazi i-ammeter shunt, ngenxa ye-coefficient yayo yokushisa ecishe ibe yiziro yokumelana nokuzinza kwesikhathi eside.Ama-Manganin resistor amaningana asebenza njengezinga elingokomthetho le-ohm e-United States kusukela ngo-1901 kuya ku-1990. Intambo ye-Manganin iphinde isetshenziswe njengekhondatha kagesi ezinhlelweni ze-cryogenic, ukunciphisa ukudluliswa kokushisa phakathi kwamaphoyinti adinga ukuxhunywa kukagesi.

I-Manganin iphinde isetshenziswe kumageji ocwaningweni lwamagagasi okwethuka komfutho ophezulu (njengalawo akhiqizwe ekuqhunyisweni kweziqhumane) ngoba inokuzwela okuphansi kobunzima kodwa izwela ingcindezi ye-hydrostatic ephezulu.

2)

Constantaniyingxubevange yethusi-nickel eyaziwa nangokuthiEureka, Phambili, futhiIsikebhe.Ngokuvamile iqukethe u-55% wethusi no-45% we-nickel.Isici sawo esiyinhloko yi-resistivity yayo, ehlala njalo phezu kwezinhlobonhlobo zamazinga okushisa.Amanye ama-alloy anama-coefficients okushisa aphansi afanayo ayaziwa, njenge-mangan (Cu86Mn12Ni2).

Esilinganisweni sezinhlobo ezinkulu kakhulu, u-5% (50 000 microstrian) noma ngaphezulu, i-annealed constantan (P alloy) yinto yegridi evame ukukhethwa.I-Constantan kuleli fomu i-ductile kakhulu;futhi, ku-gauge yobude obungu-0.125 amayintshi (3.2 mm) nangaphezulu, ingafakwa ku->20%.Kufanele kukhunjulwe, nokho, ukuthi ngaphansi kwezinhlobo eziphakeme zama-cyclic ingxubevange ye-P izobonisa ushintsho oluthile lokumelana okungapheli ngomjikelezo ngamunye, futhi ibangele ukuguquka okuhambisanayo kweqanda kugeji yobunzima.Ngenxa yalesi sici, kanye nokuthambekela kokuhluleka kwegridi ngaphambi kwesikhathi ngokuqina okuphindaphindiwe, i-P alloy ayinconywa ngokujwayelekile ezinhlelweni zohlobo lwe-cyclic.I-P ingxubevange iyatholakala nezinombolo ze-STC ezingu-08 no-40 ukuze zisetshenziswe ezinsimbi namapulasitiki, ngokulandelana.

2. Isingeniso Socingo Olunamelisiwe kanye nezinhlelo zokusebenza

Nakuba kuchazwa ngokuthi "okunoqweqwe lwawo", ucingo olunameleli alunandisiwe, empeleni, alunamekiwe ngopende lwe-koqweqwe lwawo noma ngoqweqwe lwe-vitreous olwenziwe ngempushana yengilazi ehlanganisiwe.Intambo kazibuthe yesimanje ngokuvamile isebenzisa isendlalelo esisodwa kuya kwezine (esimeni sezintambo zohlobo lwefilimu eyi-quad) ye-polymer insulation yefilimu, evamise ukuba yiziqalo ezimbili ezihlukene, ukuze zinikeze ungqimba oluqinile, oluqhubekayo lokuvikela.Amafilimu okuvikela izintambo zikazibuthe asetshenziswa (ngokulandelana kwebanga lokushisa elikhulayo) i-polyvinyl ehlelekile (Formar), i-polyurethane, i-polyimide, i-polyamide, i-polyster, i-polyester-polyimide, i-polyamide-polyimide (noma i-amide-imide), ne-polyimide.I-Polyimide insulated kazibuthe wire iyakwazi ukusebenza kufika ku-250 °C.Ukufakwa kocingo oluyisikwele olujiyile noma lukazibuthe oluwunxande kuvame ukwengezwa ngokusonga ngetheyiphu ye-polyimide noma i-fiberglass enezinga eliphezulu lokushisa, futhi ama-windings aqediwe ngokuvamile afakwa i-vacuum ngevarnish evikelayo ukuze kuthuthukiswe amandla okufaka umoya nokuthembeka kwesikhathi eside kokusonteka.

Amakhoyili azisekelayo alinyazwa ngocingo olunamekwe okungenani ngezingqimba ezimbili, engaphandle kakhulu i-thermoplastic ehlanganisa ukuphenduka ndawonye lapho kushisa.

Ezinye izinhlobo zokugquma ezifana nentambo ye-fiberglass enevarnish, iphepha le-aramid, i-kraft paper, i-mica, nefilimu ye-polyester nazo zisetshenziswa kabanzi emhlabeni wonke ekusetshenzisweni okuhlukahlukene njengama-transformer nama-reactors.Emkhakheni womsindo, intambo yokwakhiwa kwesiliva, nezinye izivikeli ezihlukene, ezifana nokotini (ngezinye izikhathi ezigcwele uhlobo oluthile lwe-ejenti ebophayo/ugqinsi, njenge-bex) ne-polytetrafluoroethylene (PTFE) ingatholwa.Izinto zokufaka ezindala zahlanganisa ukotini, iphepha, noma usilika, kodwa lezi ziwusizo kuphela ekufakweni kwezinga lokushisa eliphansi (kufika ku-105°C).

Ukuze kube lula ukukhiqiza, olunye ucingo lukazibuthe lwezinga lokushisa eliphansi lunokwahlukanisa okungasuswa ukushisa kwe-solder.Lokhu kusho ukuthi ukuxhunywa kukagesi ekugcineni kungenziwa ngaphandle kokukhumula okokufaka kuqala.

3.Ukwakheka Kwekhemikhali kanye Nempahla Eyinhloko ye-Cu-Ni Low Resistance Alloy

| PropertiesGrade | KuNi1 | KuNi2 | Kuni6 | Kunini8 | CuMn3 | KuNi10 | |

| Ukwakheka Kwamakhemikhali Okuyinhloko | Ni | 1 | 2 | 6 | 8 | _ | 10 |

| Mn | _ | _ | _ | _ | 3 | _ | |

| Cu | U-Bal | U-Bal | U-Bal | U-Bal | U-Bal | U-Bal | |

| I-Max Continuous Service Temperature(oC) | 200 | 200 | 200 | 250 | 200 | 250 | |

| I-Resisivity ku-20oC (Ωmm2/m) | 0.03 | 0.05 | 0.10 | 0.12 | 0.12 | 0.15 | |

| Ukuminyana(g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.8 | 8.9 | |

| I-Thermal Conductivity(α×10-6/oC) | <100 | <120 | <60 | <57 | <38 | <50 | |

| Amandla Okuqina (Mpa) | ≥210 | ≥220 | ≥250 | ≥270 | ≥290 | ≥290 | |

| I-EMF vs Cu(μV/oC)(0~100oC) | -8 | -12 | -12 | -22 | _ | -25 | |

| I-approximate Melting Point(oC) | 1085 | 1090 | 1095 | 1097 | 1050 | 1100 | |

| Isakhiwo seMicrographic | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | |

| Impahla Magnetic | hhayi | hhayi | hhayi | hhayi | hhayi | hhayi | |

| PropertiesGrade | CuNi14 | Kunini19 | KuNi23 | KuNi30 | CuNi34 | ICuNi44 | |

| Ukwakheka Kwamakhemikhali Okuyinhloko | Ni | 14 | 19 | 23 | 30 | 34 | 44 |

| Mn | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| Cu | U-Bal | U-Bal | U-Bal | U-Bal | U-Bal | U-Bal | |

| I-Max Continuous Service Temperature(oC) | 300 | 300 | 300 | 350 | 350 | 400 | |

| I-Resisivity ku-20oC (Ωmm2/m) | 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.49 | |

| Ukuminyana(g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| I-Thermal Conductivity(α×10-6/oC) | <30 | <25 | <16 | <10 | <0 | <-6 | |

| Amandla Okuqina (Mpa) | ≥310 | ≥340 | ≥350 | ≥400 | ≥400 | ≥420 | |

| I-EMF vs Cu(μV/oC)(0~100oC) | -28 | -32 | -34 | -37 | -39 | -43 | |

| I-approximate Melting Point(oC) | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| Isakhiwo seMicrographic | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | |

| Impahla Magnetic | hhayi | hhayi | hhayi | hhayi | hhayi | hhayi | |