I-Electric Oven Wire Isitofu sikagesi Intambo Yezimboni Isithando Somlilo Kagesi Engazweli Ukushisa

I-Electric Oven Wire Isitofu sikagesi Intambo Yezimboni Isithando Sogesi Esimelana Nokushisa

Ulwazi oluvamile

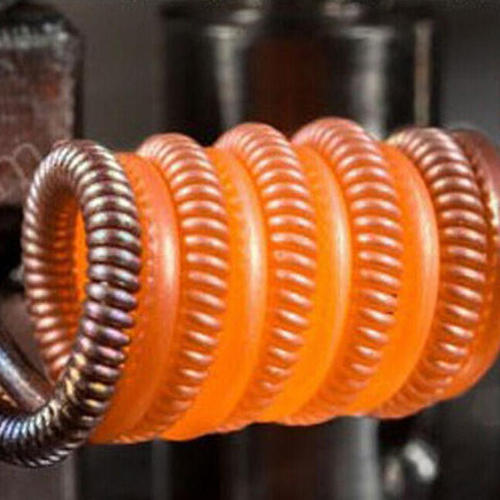

I-Electric Oven Wire iwuhlobo lwezintambo zikagesi ezikwazi ukumelana nokuqina. Intambo imelana nokugeleza kukagesi, futhi iguqula amandla kagesi abe ukushisa.

Isicelo socingo lokumelana luhlanganisa izinto eziphikisayo, izinto zokushisisa, izifudumezi zikagesi, amahhavini kagesi, amathosta nokunye okuningi.

I-Nichrome, ingxubevange engeyona-magnetic ye-nickel ne-chromium, ijwayele ukusetshenziselwa ukwenza intambo yokumelana ngoba inokumelana okuphezulu nokumelana ne-oxidation emazingeni okushisa aphezulu. Uma isetshenziswa njengento yokushisisa, intambo yokumelana ngokuvamile ifakwa amakhoyili. Obunye ubunzima ekusebenziseni i-Electric Oven Wire ukuthi i-solder kagesi evamile ngeke inamathele kuyo, ngakho-ke ukuxhunywa kwamandla kagesi kufanele kwenziwe kusetshenziswa ezinye izindlela ezifana nezixhumi ze-crimp noma amatheminali ngezikulufu.

I-FeCrAl, umndeni wama-alloys e-iron-chromium-aluminium asetshenziswa ezinhlobonhlobo eziningi zokumelana nezinga lokushisa eliphezulu nawo asetshenziswa ngendlela yezintambo zokumelana.

Izimpawu Nezakhiwo

| Ukuqokwa Okubalulekile | Elinye Igama | Ukubunjwa Kwamakhemikhali Alukhuni | |||||

| Ni | Cr | Fe | Nb | Al | Phumula | ||

| I-Nickel Chrome | |||||||

| I-Cr20Ni80 | I-NiCr8020 | 80.0 | 20.0 | ||||

| I-Cr15Ni60 | I-NiCr6015 | 60.0 | 15.0 | 20.0 | |||

| I-Cr20Ni35 | I-NiCr3520 | 35.0 | 20.0 | 45.0 | |||

| I-Cr20Ni30 | I-NiCr3020 | 30.0 | 20.0 | 50.0 | |||

| I-Iron Chrome Aluminium | |||||||

| OCr25Al5 | I-CrAl25-5 | 23.0 | 71.0 | 6.0 | |||

| OCr20Al5 | I-CrAl20-5 | 20.0 | 75.0 | 5.0 | |||

| I-OCr27Al7Mo2 | 27.0 | 65.0 | 0.5 | 7.0 | 0.5 | ||

| I-OCr21Al6Nb | 21.0 | 72.0 | 0.5 | 6.0 | 0.5 | ||

| Ukuqokwa Okubalulekile | Ukumelana µOhms/cm | Ukuminyana G/cm3 | I-Coefficient of Linear Expansion | I-Thermal Conductivity W/mK | |

| µm/m.°C | Izinga lokushisa.°C | ||||

| I-Nickel Chrome | |||||

| I-Cr20Ni80 | 108.0 | 8.4 | 17.5 | 20-1000 | 15.0 |

| I-Cr15Ni60 | 112.0 | 8.2 | 17.5 | 20-1000 | 13.3 |

| I-Cr20Ni35 | 105.0 | 8.0 | 18.0 | 20-1000 | 13.0 |

| I-Iron Chrome Aluminium | |||||

| OCr25Al5 | 145.0 | 7.1 | 15.1 | 20-1000 | 16.0 |

| OCr20Al5 | 135.0 | 7.3 | 14.0 | 20-1000 | 16.5 |

Izinhlelo zokusebenza eziphakanyisiwe

| Ukuqokwa Okubalulekile | Izakhiwo Zesevisi | Izinhlelo zokusebenza |

| I-Nickel Chrome | ||

| I-Cr20Ni80 | Iqukethe izengezo zempilo ende okwenza ifaneleke ngokuvelele izinhlelo zokusebenza ezingaphansi kokushintsha njalo kanye nokuguquguquka okubanzi kwezinga lokushisa. Ingasetshenziswa emazingeni okushisa okusebenza afinyelela ku-1150 °C. | Lawula ama-resistors, izithando zokushisa eziphezulu, izinsimbi zokunamathisela. |

| I-Cr15Ni60 | Ingxubevange ye-Ni/Cr enebhalansi ngokuyinhloko i-Iron, enezengezo zempilo ende. Ifanele ukusetshenziswa kufika ku-1100 °C, kodwa i-coefficient ephakeme yokumelana iyenza ifanelekele izinhlelo zokusebenza ezingabizi kakhulu kuno-80/20. | Izifudumezi zikagesi, izinsimbi ezisindayo, iziko likagesi. |

| I-Cr20Ni35 | Ibhalansi ngokuyinhloko Iron. Ifanele ukusebenza okuqhubekayo kufika ku-1050°C, ezithandweni ezinomkhathi okungase kubangele ukugqwala okomile kokuqukethwe okuphezulu kwe-nickel. | Izifudumezi zikagesi, izithando zikagesi (ezinomoya). |

| I-Iron Chrome Aluminium | ||

| OCr25Al5 | Ingasetshenziswa ezimeni zokusebenza ezifika ku-1350°C, nakuba zingaba ne-embrittled. | Izakhi zokushisa zamaziko okushisa aphezulu nama-heaters akhazimulayo. |

| OCr20Al5 | Ingxubevange ye-ferromagnetic engasetshenziswa emazingeni okushisa afinyelela ku-1300°C. Kufanele isetshenziswe endaweni eyomile ukugwema ukugqwala. Kungaba ebrittled emazingeni okushisa aphezulu. | Izakhi zokushisa zamaziko okushisa aphezulu nama-heaters akhazimulayo. |

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

Whatsapp

-

I-WeChat

Judy

150 0000 2421

-

Phezulu