Ikhoyili yasentwasahlobo

pincazelo yomzila

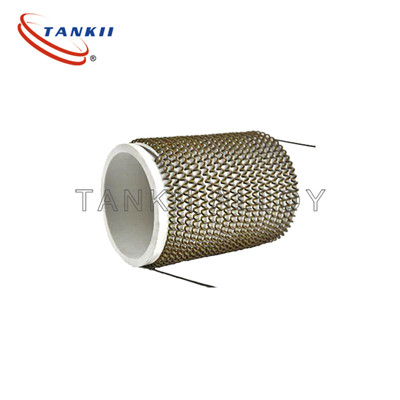

Inkampani yethu ikhiqiza izintambo ezisezingeni eliphezulu ze-iron-chromium-aluminium kanye ne-nickel-chromium kagesi yokufudumeza ingxubevange, ezisebenzisa amandla ezintambo zesithando somlilo ezilawulwa ngekhompiyutha futhi zilinyazwa ukwakheka umshini ozenzakalelayo ojikajikayo onesivinini esikhulu.Izici zalo mkhiqizo: ukumelana nokushisa okuphezulu, ukushisa okusheshayo, impilo ende yesevisi, ukumelana okuzinzile, ukuphambuka kwamandla amancane, i-pitch efanayo ngemva kokwelula, indawo ekhanyayo nehlanzekile;esetshenziswa kabanzi ezithandweni zikagesi ezincane, izifutho ze-muffle, izinto zokufudumeza nezomoya, amahhavini ahlukahlukene, amashubhu okushisa kagesi nezinto zikagesi zasendlini, njll.

| Amandla W | Vi-oltage V | Ububanzi mm | OD mm | Length (Inkomba) mm | Wisishiyagalombili g |

| 300 | 220 | 0.25 | 3.7 | 122 | 1.9 |

| 500 | 220 | 0.35 | 3.9 | 196 | 4.3 |

| 600 | 220 | 0.40 | 4.2 | 228 | 6.1 |

| 800 | 220 | 0.50 | 4.7 | 302 | 11.1 |

| 1000 | 220 | 0.60 | 4.9 | 407 | 18.5 |

| 1200 | 220 | 0.70 | 5.6 | 474 | 28.5 |

| 1500 | 220 | 0.80 | 5.8 | 554 | 39.0 |

| 2000 | 220 | 0.95 | 6.1 | 676 | 57.9 |

| 2500 | 220 | 1.10 | 6.9 | 745 | 83.3 |

| 3000 | 220 | 1.20 | 7.1 | 792 | 98.3 |

Izinga lokushisa kanye nokwakheka kwamakhemikhali kwentambo yokushisisa

| Ibanga | Ubukhulu.Qhubeka I-Operating Temper. | Cr% | Ni% | Al% | Fe% | Re% | Nb% | Mo% |

| I-Cr20Ni80 | 1200 ℃ | 20~23 | U-Bal. |

|

|

|

|

|

| I-Cr30Ni70 | 1250 ℃ | 28-31 | U-Bal. |

|

|

|

|

|

| I-Cr15Ni60 | 1150 ℃ | 15-18 | 55; 61 |

| U-Bal. |

|

|

|

| I-Cr20Ni35 | 1100 ℃ | 18-21 | 34; 37 |

| U-Bal. |

|

|

|

| TANKII APM | 1425℃ | 20.5~23.5 |

| 5.8 | U-Bal. | / |

|

|

| 0Cr27Al7Mo2 | 1400 ℃ | 26.5~27.8 |

| 6~7 | U-Bal. |

|

| 2 |

| 0Cr21Al6Nb | 1350 ℃ | 21-23 |

| 5~7 | U-Bal. |

| 0.5 |

|

| 0Cr25Al5 | 1250 ℃ | 23-26 |

| 4.5~6.5 | U-Bal. |

|

|

|

| 0Cr23Al5Y | 1300 ℃ | 22.5~24.5 |

| 4.2~5.0 | U-Bal. |

|

|

|

| 0Cr19Al3 | 1100 ℃ | 18-21 |

| 3~4.2 | U-Bal. |

|

|

|

Izakhiwo eziyinhloko zobuchwepheshe ze-FeCrAl alloy wire:

① Izinga lokushisa lokusetshenziswa liphezulu, izinga lokushisa lokusetshenziswa kwe-iron-chromium aluminium alloy wire emkhathini lingafinyelela ku-1300℃;

②Impilo ende yesevisi;

③Umthwalo wendawo ovunyelwe mkhulu;

⑤Amandla adonsela phansi athile mancane kunengxubevange ye-nickel-chromium;④Ukumelana ne-oxidation kuhle, futhi ifilimu ye-AI2O3 eyakhiwe ngemva kwe-oxidation inokumelana okuhle kwamakhemikhali kanye nokumelana okuphezulu;

⑥Ukumelana okuphezulu;

⑦Ukumelana kahle nesibabule;

⑧Intengo iphansi kakhulu kunaleyo ye-nickel-chromium alloy;

⑨Ububi ukuthi njengoba izinga lokushisa likhuphuka, libonisa ipulasitiki, futhi amandla emazingeni okushisa aphansi.

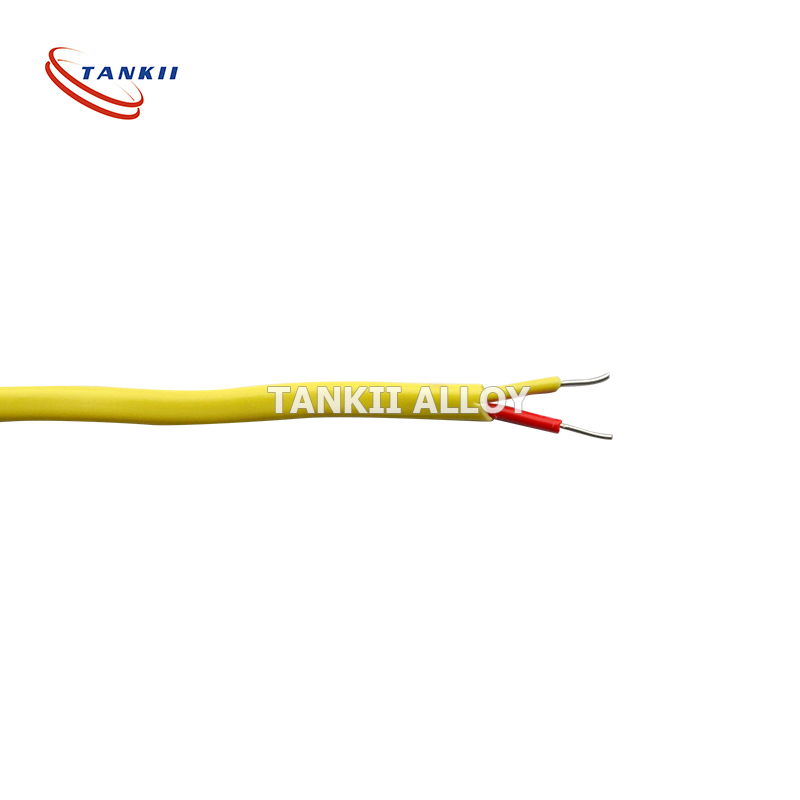

Izici zocingo lwesitofu sikagesi se-nickel-chromium yilezi:

① Amandla aphezulu ekushiseni okuphezulu;

②Phola ngemva kokusetshenziswa isikhathi eside, okokusebenza ngeke kube nzima;

③Ukukhishwa kwengxube ye-Ni-ming egcwele oxidized kungaphezulu kwalokho kwe-Fe-Cr-Al alloy;

④Awukho uzibuthe;

⑤Ngaphandle komkhathi wesulfure, inokumelana nokugqwala okungcono