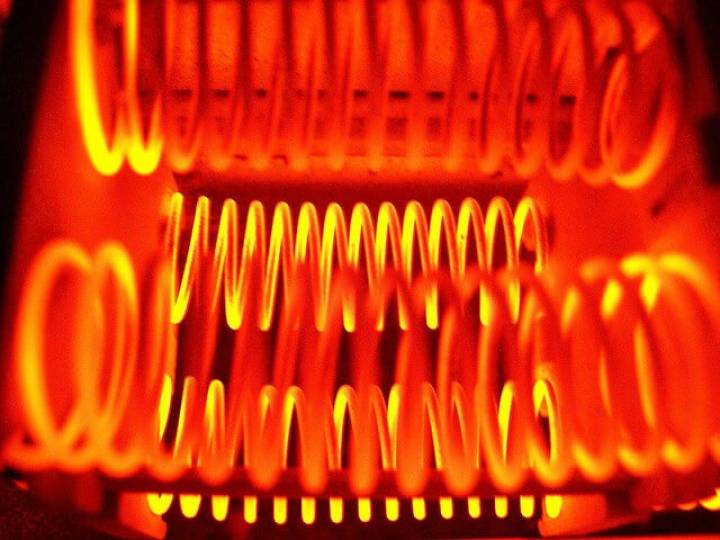

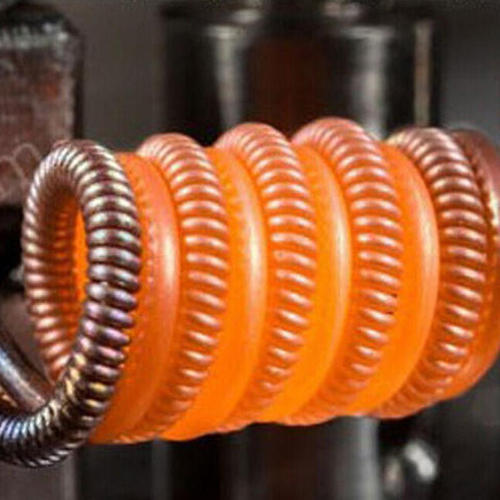

Ikhoyili yokushisa ye-FeCrAl 0Cr25Al5 yokushisa isitofu sikagesi

Impahla Eyinhloko yentambo yokumelana nokushisa

| Uhlobo lwe-alloy | Ububanzi (mm) | Ukumelana (μΩm)(20°C) | Ukuthamba Amandla (N/mm²) | Ukwelulwa (%) | Ukugoba Izikhathi | Ubuningi.Okuqhubekayo Isevisi Izinga lokushisa(°C) | Impilo Yokusebenza (amahora) |

| I-Cr20Ni80 | <0.50 | 1.09±0.05 | 850-950 | >20 | >9 | 1200 | >20000 |

| 0.50-3.0 | 1.13±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| >3.0 | 1.14±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| I-Cr30Ni70 | <0.50 | 1.18±0.05 | 850-950 | >20 | >9 | 1250 | >20000 |

| ≥0.50 | 1.20±0.05 | 850-950 | >20 | >9 | 1250 | >20000 | |

| I-Cr15Ni60 | <0.50 | 1.12±0.05 | 850-950 | >20 | >9 | 1125 | >20000 |

| ≥0.50 | 1.15±0.05 | 850-950 | >20 | >9 | 1125 | >20000 | |

| I-Cr20Ni35 | <0.50 | 1.04±0.05 | 850-950 | >20 | >9 | 1100 | >18000 |

| ≥0.50 | 1.06±0.05 | 850-950 | >20 | >9 | 1100 | >18000 | |

| 1Cr13Al4 | 0.03-12.0 | 1.25±0.08 | 588-735 | >16 | >6 | 950 | >10000 |

| 0Cr15Al5 | 1.25±0.08 | 588-735 | >16 | >6 | 1000 | >10000 | |

| 0Cr25Al5 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 0Cr23Al5 | 1.35±0.06 | 634-784 | >12 | >5 | 1250 | >8000 | |

| 0Cr21Al6 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 1Cr20Al3 | 1.23±0.06 | 634-784 | >12 | >5 | 1100 | >8000 | |

| 0Cr21Al6Nb | 1.45±0.07 | 634-784 | >12 | >5 | 1350 | >8000 | |

| 0Cr27Al7Mo2 | 0.03-12.0 | 1.53±0.07 | 686-784 | >12 | >5 | 1400 | >8000 |

| IGAMA | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| AMAKHEMIKALI AYINHLOKO | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 22.5-24.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.0 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| UKWAKHIWA | Re | ithuba | ithuba | ithuba | ithuba | ithuba | ithuba | ithuba |

| Fe | Ukuphumula | Ukuphumula | Ukuphumula | Ukuphumula | Ukuphumula | Ukuphumula | Ukuphumula | |

| Inombolo 0.5 | UMsombuluko 1.8-2.2 | |||||||

| IZINGQONDO EZIPHEZULU (oC) | 650 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| UKUMELANA 20oC (μΩ·m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| UKUMINYANA (g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

| UKUSHINTSHANA NGOSHISA | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | 45.2 | |

| IZINGA(KJ/m·h·oC) | ||||||||

| izinga lokunwetshwa (α×10-6/oC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

| iphuzu lokuncibilika (oC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| amandla okudonsa (N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| ukunwebeka(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| ukuhlukahluka kwendawo(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| imvamisa yokugoba (F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| ubulukhuni (HB) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| isakhiwo se-micrographic | I-Ferrite | I-Ferrite | I-Ferrite | I-Ferrite | I-Ferrite | I-Ferrite | I-Ferrite | |

| impahla kazibuthe | Uzibuthe | Uzibuthe | Uzibuthe | Uzibuthe | Uzibuthe | Uzibuthe | Uzibuthe | |

| Ububanzi(mm) | Ukubekezelelana (mm) | Ububanzi(mm) | Ukubekezelelana (mm) |

| 0.03-0.05 | ±0.005 | >0.50-1.00 | ±0.02 |

| >0.05-0.10 | ±0.006 | >1.00-3.00 | ±0.03 |

| >0.10-0.20 | ±0.008 | >3.00-6.00 | ±0.04 |

| >0.20-0.30 | ±0.010 | >6.00-8.00 | ±0.05 |

| >0.30-0.50 | ±0.015 | >8.00-12.0 | ±0.4 |

| Ubukhulu (mm) | Ukubekezelelana (mm) | Ububanzi(mm) | Ukubekezelelana (mm) |

| 0.05-0.10 | ±0.010 | 5.00-10.0 | ±0.2 |

| >0.10-0.20 | ±0.015 | >10.0-20.0 | ±0.2 |

| >0.20-0.50 | ±0.020 | >20.0-30.0 | ±0.2 |

| >0.50-1.00 | ±0.030 | >30.0-50.0 | ±0.3 |

| >1.00-1.80 | ±0.040 | >50.0-90.0 | ±0.3 |

| >1.80-2.50 | ±0.050 | >90.0-120.0 | ±0.5 |

| >2.50-3.50 | ±0.060 | >120.0-250.0 | ±0.6 |

Singumkhiqizi wezintambo zokumelana nokushisa ezifaka phakathi

Intambo ye-FeCrAL, intambo ye-NiCr, intambo ye-CuNi:

II Inzuzo Eyinhloko kanye Nokusetshenziswa

A. Ipharamitha ebonakalayo:

1) Ububanzi bentambo: 0.025 ~ 15mm

2) I-nickel emsulwa inamandla okubekezelela amazinga okushisa aphezulu ngaphandle kokuwohloka. Ukusebenza okuphezulu kakhulu

izinga lokushisa lilinganiselwa ku-600°C

3) Ucingo lwe-nickel luyatholakala ngokwakhiwa komucu owodwa noma wemicu eminingi. Lutholakala kusuka esitokweni noma lungenalutho, noma lufakwe uthayela

B. Izici:

1) Ukuqondakala okuhle kakhulu

2) Isimo sobuso esifanayo nesinhle esingenamabala

3) Ikhono elihle kakhulu lokwenza ikhoyili

C. Izicelo eziyinhloko kanye nenhloso ejwayelekile:

1) Le ntambo ingasetshenziswa kabanzi kuma-transistor caps, ama-anode amashubhu kagesi,

izintambo zezingxenye ze-elekthronikhi / izintambo ze-lead-in zezibani kanye neze-wire-mesh. Zisetshenziswa futhi ngesimo somugqa wezinto ezahlukene

izinhlelo zokusebenza ezifaka phakathi amabhethri e-Ni-Cd

2) Iphinde isetshenziswe kumakhebula, i-Lead-in-Wire yezibani, izisekelo zamashubhu kagesi, ama-lead okuxhuma kagesi ngendwangu yocingo

lapho amazinga okushisa edlula lawo afanele ithusi, ukuluka ucingo

3) Izicelo ezijwayelekile zifaka: iziphetho zezinto zokushisa njengakuma-oven, amapulasitiki, ama-extruder, ama-furnace.

Izisekelo zefilament kanye nezintambo zomthofu embonini yokukhanyisa

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu