I-Zinc emsulwa/i-Monel 400/i-Tafa 70t/i-Monel K500/i-Ernicu-7/i-Ni95al5/i-Tafa 75b/i-Hastalloy C-276 Insimbi Engagqwali ye-Nickel Alloy Thermal Spray Wire

I-Zinc Emsulwa/I-Monel 400/I-Tafa 70t/I-Monel K500/Ernicu-7/I-Ni95al5/I-Tafa 75b/I-Hastalloy C-276Intambo Yokufutha Engagqwali Yensimbi Engagqwali

Incazelo Yomkhiqizo

1. I-FM60 Oxford Alloy 60I-ERNiCu-7Induku yokushisela ye-TIG

I-ERNiCu-7inamandla amahle futhi imelana nokugqwala ezindaweni eziningi, okuhlanganisa amanzi olwandle, usawoti, kanye nama-asidi anciphisayo. Futhi ingasetshenziswa ukumboza insimbi yekhabhoni, uma nje kusetshenziswa ungqimba lwe-buffer lwe-ERNi-1 lwesendlalelo sokuqala. Le alloy ayigugi futhi uma isetshenziswa ukujoyina i-Monel K-500 inamandla aphansi kunensimbi eyisisekelo.

Amagama Avamile: I-Oxford Alloy® 60 FM 60 I-Techalloy 418

Izinga: AWS 5.14 Ikilasi ERNiCu-7 / ASME SFA 5.14 Ikilasi ERNiCu-7 ASME II, SFA-5.14 UNS N04060 Werkstoff Nr. 2.4377 ISO SNi4060 Europe NiCu30Mn3Ti

UKWAKHIWA KWAMAKHEMIKI (%)

| C | Si | Mn | S | P | Ni |

| ≤0.15 | ≤1.25 | ≤4.0 | ≤0.015 | ≤0.02 | 62-69 |

| Al | Ti | Fe | Cu | abanye | |

| ≤1.25 | 1.5-3.0 | ≤2.5 | Ukuphumula | <0.5 |

AMAPHARAMETHI OKUSHINTSHA

| Inqubo | Ububanzi | I-voltage | I-Amperage | Igesi |

| I-TIG | .035″ (0.9mm) .045″ (1.2mm) 1/16″ (1.6mm) 3/32″ (2.4mm) 1/8″ (3.2mm) | 12-15 13-16 14-18 15-20 15-20 | 60-90 80-110 90-130 120-175 150-220 | 100% Argon 100% Argon 100% Argon 100% Argon 100% Argon |

| I-MIG | .035″ (0.9mm) .045″ (1.2mm) 1/16″ (1.6mm) | 26-29 28-32 29-33 | 150-190 180-220 200-250 | 75% Argon+25% Helium 75% Argon+25% Helium I-Argon engu-75% + 25% i-Helium |

| I-SAW | 3/32″ (2.4mm) 1/8″ (3.2mm) 5/32″ (4.0mm) | 28-30 29-32 30-33 | 275-350 350-450 400-550 | I-Flux efanelekile ingasetshenziswa I-Flux efanelekile ingasetshenziswa I-Flux efanelekile ingasetshenziswa |

IZINDAWO ZOMKHANIKHANI

| Amandla Okudonsa | I-PSI engu-76,5000 | 530 MPA |

| Amandla Okukhiqiza | 52,500 PSI | I-MPA engu-360 |

| Ukwelulwa | 34% |

IZICELO

I-ERNiCu-7 ingasetshenziswa ekusetshenzisweni okuhlukahlukene kokushisela kusetshenziswa ama-alloy ahlukahlukene e-nickel-copper kuya ku-nickel 200 kanye nama-alloy e-copper-nickel.

I-ERNiCu-7 isetshenziselwa ukushisela i-gas-tungsten-arc, i-gas-metal-arc, kanye ne-submeded-arc welding ye-Monel alloy 400 kanye ne-K-500.

I-ERNiCu-7 isetshenziswa kabanzi ekusetshenzisweni kwasolwandle ngenxa yokumelana kwayo okuhle nemiphumela yokugqwala kwamanzi olwandle namanzi anosawoti.

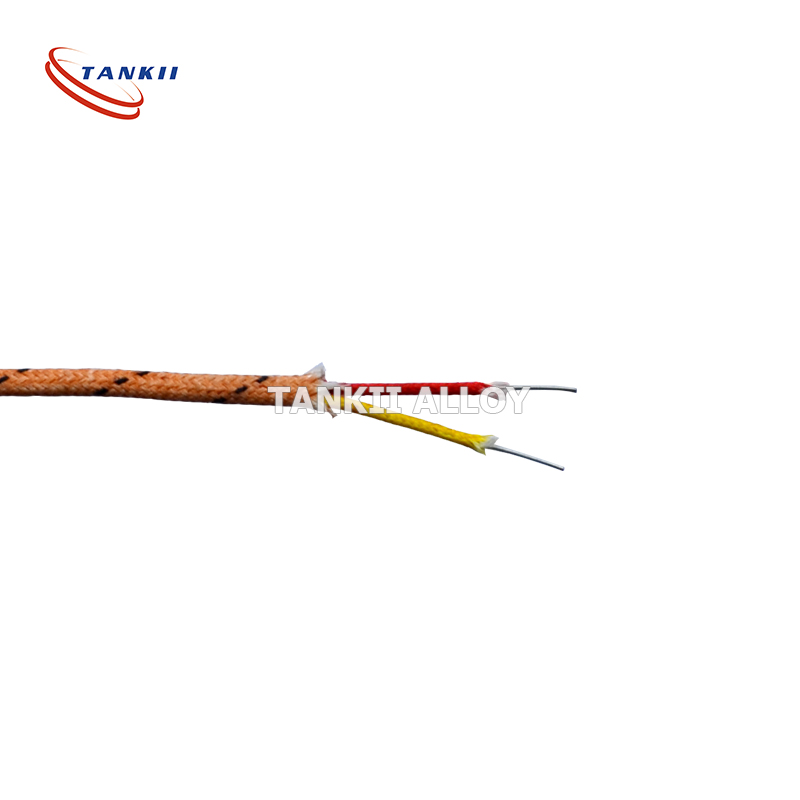

2. Olunye ucingo lwe-Thermal Spray

| Into | Okuqukethwe kwamakhemikhali | Zn | Cd | Pb | Fe | Cu | Isamba Sebhalansi |

| i-zinc emsulwa | Inani elilinganiselwe | ≥99.995 | ≤0.002 | ≤0.003 | ≤0.002 | ≤0.001 | 0.005 |

| Into | I-Inconel 625 | I-Ni95Al5 | 45CT | I-Monel 400 | I-Monel 500 | I-HC-276 | I-Cr20Ni80 |

| C | ≤0.05 | ≤0.02 | 0.01-0.1 | ≤0.04 | ≤0.25 | ≤0.02 | ≤0.08 |

| Mn | ≤0.4 | ≤0.2 | ≤0.2 | 2.5-3.5 | ≤1.5 | ≤1.0 | ≤0.06 |

| Fe | ≤1.0 | Akukho | ≤0.5 | ≤1.0 | ≤1.0 | 4.0-7.0 | Akukho |

| P | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.02 |

| S | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 |

| Si | ≤0.15 | ≤0.2 | ≤0.2 | ≤0.15 | ≤0.5 | ≤0.08 | 0.75-1.6 |

| Cu | Akukho | Akukho | Akukho | ukuphumula | 27-33 | Akukho | Akukho |

| Ni | ukuphumula | ukuphumula | ukuphumula | 65-67 | ukuphumula | ukuphumula | ukuphumula |

| Co | Akukho | Akukho | Akukho | Akukho | Akukho | Akukho | Akukho |

| Al | ≤0.4 | 4-5 | Akukho | ≤0.5 | 2.3-3.15 | Akukho | Akukho |

| Ti | ≤0.4 | 0.4-1 | 0.3-1 | 2.0-3 | 0.35-0.85 | Akukho | Akukho |

| Cr | 21.5-23 | ≤0.2 | 42-46 | Akukho | Akukho | 14.5-16 | 20-23 |

| Nb | 3.5-4.15 | Akukho | Akukho | Akukho | Akukho | Akukho | ≤1.0 |

| Mo | 8.5-10 | Akukho | Akukho | Akukho | Akukho | 15-17 | Akukho |

| V | Akukho | Akukho | Akukho | Akukho | Akukho | ≤0.35 | Akukho |

| W | Akukho | Akukho | Akukho | Akukho | Akukho | 3.0-4.5 | Akukho |

| Ukungcola | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 |

3. C276ucingo lokufutha olushisayo

Amagama Avamile: I-Oxford Alloy® C-276 FM C-276 I-Techalloy 276

Okujwayelekile: AWS A5.14, ERNiCrMo-4/ ASME II, SFA-5.14, UNS N10276 Werkstoff Nr. 2.4886 ISO SNi6276 Europe NiCrMo16Fe6W4

UKWAKHIWA KWAMAKHEMIKI (%)

| C | Si | Mn | S | P | Ni | Co |

| ≤0.02 | ≤0.08 | ≤1.0 | ≤0.03 | ≤0.04 | Ukuphumula | ≤2.5 |

| W | V | Fe | Cu | Cr | Mo | abanye |

| 3.0-4.5 | ≤0.35 | 4.0-7.0 | ≤0.5 | 14.5-16.5 | 15-17 | <0.5 |

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu