Siyakwamukela kumawebhusayithi ethu!

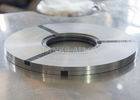

Ama-Resistors Acwebezelayo Ayisicaba 5mm Ububanzi 1Cr13Al4 FeCrAl intambo yokumelana

I-1Cr13Al4 FeCrAl alloy Bright Flat Strip/ Wide Strip yokusetshenziswa kwama-Resistors

Ama-Fecral Alloys kanye nama-Nickel-chromium alloys akhethwe ukuba abe yizinto ezivikelayo ze-resistor ehlanganisiwe ngoba ama-nickel-chromium alloys anokumelana okuphezulu kukagesi okusetshenziswa kabanzi kuma-resistors efilimu encane [1, 2]. Ukumelana kweshidi lefilimu ye-nickel-chrome alloy equkethe i-20% chromium kungaba phezulu njenge-2-3 kilo ohms futhi kusalokhu kugcina ukuzinza okuhle. I-coefficient yokushisa 1 yokumelana (TCR) ye-bulk nickel-chrome alloy cishe i-110 ppm/°C. Ngokuhlanganisa inani elincane le-silicon ne-aluminium nge-nickel-chromium, ukuzinza kokushisa kuyathuthukiswa kakhulu.

Isicelo:

Ama-resistors afakwe ebhodini lokuxhuma eliphrintiwe azoba yisivikelo sokwenza amaphakheji amancane abe nokuthembeka okuphezulu kanye nokusebenza kukagesi okuthuthukisiwe. Ukuhlanganisa ukusebenza kwe-resistor ku-substrate ye-laminate kukhulula indawo engaphezulu ye-PWB edliwa yizingxenye ezihlukene, okuvumela ukusebenza okwengeziwe kwedivayisi ngokubeka izingxenye ezisebenzayo kakhulu. Ama-alloy e-nickel-chromium anokumelana okuphezulu kukagesi, okwenza kube lula ukusetshenziswa ezinhlotsheni ezahlukahlukene zokusebenza. I-nickel ne-chromium zixutshwa ne-silicon ne-aluminium ukuthuthukisa ukuzinza kokushisa nokwehlisa i-coefficient yokumelana nokushisa. Ingqimba encane yokumelana nefilimu esekelwe kuma-alloy e-nickel-chromium ibekwe njalo emiqulwini ye-foil yethusi ukudala izinto zokusetshenziswa kwe-resistor ehlanganisiwe. Ingqimba encane yokumelana nefilimu ehlanganisiwe phakathi kwethusi ne-laminate ingaqoshwa ngokukhetha ukuze yakhe ama-resistors ahlukene. Amakhemikhali okuqothula avamile ezinqubweni zokukhiqiza ze-PWB. Ngokulawula ukujiya kwama-alloy, kutholakala amanani okumelana neshidi kusuka ku-25 kuya ku-250 ohm/sq. Leli phepha lizoqhathanisa izinto ezimbili ze-nickel-chromium ezindleleni zazo zokugoba, ukufana, ukuphathwa kwamandla, ukusebenza kokushisa, ukunamathela kanye nesisombululo sokugoba.

Ama-resistors afakwe ebhodini lokuxhuma eliphrintiwe azoba yisivikelo sokwenza amaphakheji amancane abe nokuthembeka okuphezulu kanye nokusebenza kukagesi okuthuthukisiwe. Ukuhlanganisa ukusebenza kwe-resistor ku-substrate ye-laminate kukhulula indawo engaphezulu ye-PWB edliwa yizingxenye ezihlukene, okuvumela ukusebenza okwengeziwe kwedivayisi ngokubeka izingxenye ezisebenzayo kakhulu. Ama-alloy e-nickel-chromium anokumelana okuphezulu kukagesi, okwenza kube lula ukusetshenziswa ezinhlotsheni ezahlukahlukene zokusebenza. I-nickel ne-chromium zixutshwa ne-silicon ne-aluminium ukuthuthukisa ukuzinza kokushisa nokwehlisa i-coefficient yokumelana nokushisa. Ingqimba encane yokumelana nefilimu esekelwe kuma-alloy e-nickel-chromium ibekwe njalo emiqulwini ye-foil yethusi ukudala izinto zokusetshenziswa kwe-resistor ehlanganisiwe. Ingqimba encane yokumelana nefilimu ehlanganisiwe phakathi kwethusi ne-laminate ingaqoshwa ngokukhetha ukuze yakhe ama-resistors ahlukene. Amakhemikhali okuqothula avamile ezinqubweni zokukhiqiza ze-PWB. Ngokulawula ukujiya kwama-alloy, kutholakala amanani okumelana neshidi kusuka ku-25 kuya ku-250 ohm/sq. Leli phepha lizoqhathanisa izinto ezimbili ze-nickel-chromium ezindleleni zazo zokugoba, ukufana, ukuphathwa kwamandla, ukusebenza kokushisa, ukunamathela kanye nesisombululo sokugoba.

Izinto ze-alloy

olunye uchungechunge lomkhiqizo:

I-FeCrAl Alloy: OCr15Al5,1Cr13Al4, 0Cr21Al4, 0Cr19Al3, 0Cr21Al6, 0Cr25Al5, 0Cr21Al6Nb,0Cr27Al7Mo2.

I-NiCr Alloy: Cr20Ni80, Cr30Ni70, Cr20Ni35, Cr20Ni30, Cr15Ni60.

I-CuNi Alloy: NC003,NC010,NC012,NC015,NC020,NC025,NC030,NC040,NC050,Constantan,6J8/11/12/13/.

Intambo yokushisela: ERNiCrMo-3/4/13,ERNiCrFe-3/7,ERNiCr-3/7,ERNiCu-7,ERNi-1, ER70S-6.

I-alloy ye-thermocouple: K,J,E,T,N, S,R,B,KX,JX,EX,TX,NX.

Ingxubevange ye-Inconel: Inconel 600,601,617,X-750,625,690,718,825.

Ingxubevange ye-Incoloy: Incoloy 800,800H,800HT,825,925.

Ingxubevange ye-Hastelloy: HC-276,C-22,C-4,HB,B/2/3,X,N.

I-Monel Alloy: I-Monel 400,K500.

Ingxubevange yokushisa okuphezulu: A-286,Nimonic80A/90,GH131,GH1140,GH36,GH2706,GH2901,GH3625,GH3536,GH4169.

Uchungechunge lwe-alloy olunembile: 1J33,3J01,3J9,4J29,4J32.4J33,Invar36,4J45.FeNi50.

Ingxubevange yesifutho esishisayo: Inconel 625,Ni95Al5,Monel400,45CT,HC-276,K500,Cr20Ni80.

olunye uchungechunge lomkhiqizo:

I-FeCrAl Alloy: OCr15Al5,1Cr13Al4, 0Cr21Al4, 0Cr19Al3, 0Cr21Al6, 0Cr25Al5, 0Cr21Al6Nb,0Cr27Al7Mo2.

I-NiCr Alloy: Cr20Ni80, Cr30Ni70, Cr20Ni35, Cr20Ni30, Cr15Ni60.

I-CuNi Alloy: NC003,NC010,NC012,NC015,NC020,NC025,NC030,NC040,NC050,Constantan,6J8/11/12/13/.

Intambo yokushisela: ERNiCrMo-3/4/13,ERNiCrFe-3/7,ERNiCr-3/7,ERNiCu-7,ERNi-1, ER70S-6.

I-alloy ye-thermocouple: K,J,E,T,N, S,R,B,KX,JX,EX,TX,NX.

Ingxubevange ye-Inconel: Inconel 600,601,617,X-750,625,690,718,825.

Ingxubevange ye-Incoloy: Incoloy 800,800H,800HT,825,925.

Ingxubevange ye-Hastelloy: HC-276,C-22,C-4,HB,B/2/3,X,N.

I-Monel Alloy: I-Monel 400,K500.

Ingxubevange yokushisa okuphezulu: A-286,Nimonic80A/90,GH131,GH1140,GH36,GH2706,GH2901,GH3625,GH3536,GH4169.

Uchungechunge lwe-alloy olunembile: 1J33,3J01,3J9,4J29,4J32.4J33,Invar36,4J45.FeNi50.

Ingxubevange yesifutho esishisayo: Inconel 625,Ni95Al5,Monel400,45CT,HC-276,K500,Cr20Ni80.

Bhala umlayezo wakho lapha bese uwuthumela kithi

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu