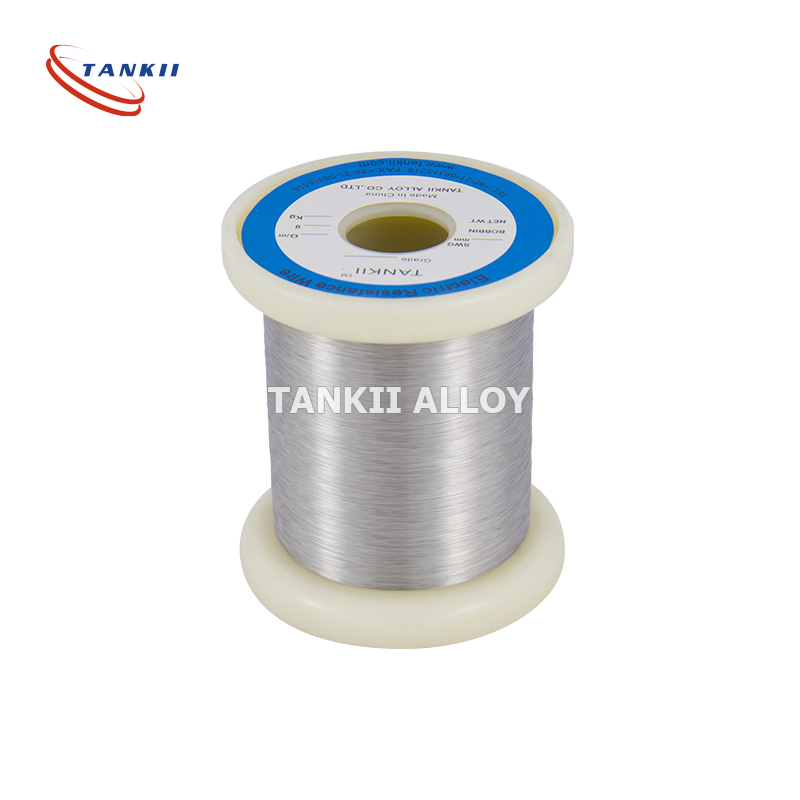

1mm*10mm 0Cr25Al5 Flat Ribbon Round Burr FeCrAl Resistance Wire

Intengo yesitoko 1mm*10mm 0Cr25Al5 Flat Ribbon Round Burr Bright Surface Strip

1. Isingeniso

Ama-alloys e-FeCrAl asetshenziswa ezinhlobonhlobo zezinhlelo zokusebenza ezishisa kakhulu.

I-Constantan [Cu55Ni45] ine-coefficient yokushisa ephansi ye-resistivity futhi njenge-alloy yethusi, idayiswa kalula.Amanye ama-alloys amelana njalo ahlanganisa i-mangan [Cu86Mn12Ni2], Cupron [Cu53Ni44Mn3] kanye ne-Evanohm.

Umndeni wakwa-Evanohm wama-alloys e-nickel-chrome [Ni72Cr20Mn4Al3Si1], [Ni73Cr20Cu2Al2Mn1Si], unokumelana okuphezulu, izinga lokushisa eliphansi le-coefficient of resistance, amandla aphansi e-electromotive (amandla e-Galvani) lapho uthintana nethusi, amandla aphezulu aqinile, futhi futhi azinzile kakhulu mayelana ukushisa ukwelashwa.

2. Ukucaciswa:

| Ibanga | Ukwakheka kwamakhemikhali okuyinhloko | Izinga lokushisa eliphezulu ℃ | I-Rrisistivity µΩ.m | Iphuzu lokuncibilika ℃ | Amandla aqinile N/mm² | Elogation % | Impilo yokusebenza h/℃ | Uzibuthe izakhiwo | |||

| Cr | Al | Ni | Fe | ||||||||

| OCr21Al4 | 17-21 | 3-4 | - | - | 1100 | 1.23±0.06 | 1500 | 750 | ≥12 | ≥80/1250 | kazibuthe |

| OCr25Al5 | 23-26 | 4.5-6.5 | - | - | 1250 | 1.42±0.07 | 1500 | 750 | ≥12 | ≥80/1300 | kazibuthe |

| I-OCr21Al6Nb | 21-23 | 5-7 | - | - | 1350 | 1.43±0.07 | 1510 | 750 | ≥12 | ≥50/1350 | kazibuthe |

| I-OCr27Al7Mo2 | 22-24 | 5-7 | - | - | 1400 | 1.53±0.07 | 1520 | 750 | ≥10 | ≥50/1350 | kazibuthe |

| I-KSC | 26.8-27.8 | 6-7 | - | - | 1350 | 1.44±0.05 | 1510 | 750 | ≥16 | ≥60/1350 | kazibuthe |

| I-Cr20Ni80 | 20-23 | - | Phumula | ≤1.0 | 1200 | 1.09±0.05 | 1400 | 750 | ≥20 | ≥80/1200 | Okungewona uzibuthe |

| I-Cr30Ni70 | 30 | - | Phumula | ≤1.0 | 1250 | 1.18±0.05 | 1380 | 750 | ≥20 | ≥50/1250 | Okungewona uzibuthe |

| I-Cr15Ni60 | 15-18 | - | 55 | Phumula | 1150 | 1.12±0.05 | 1390 | 750 | ≥20 | ≥80/1150 | Okungewona uzibuthe |

| I-Cr20Ni35 | 18-21 | - | 35 | Phumula | 1100 | 1.04±0.05 | 1390 | 750 | ≥20 | ≥80/1100 | Uzibuthe obuthakathaka |

| I-Cr20Ni30 | 20 | - | 32 | Phumula | 1100 | 1.04±0.05 | 1390 | 750 | ≥20 | ≥80/1100 | Uzibuthe obuthakathaka |

3.

| Okubalulekile | Ukungazweli (ohm-cmil/ft) | Ukungazweli (10−6ohm-cm) |

|---|---|---|

| I-Aluminium | 15.94 | 2.650 |

| Ithusi | 42.1 | 7.0 |

| Ikhabhoni (i-amorphous) | 23 | 3.95 |

| Constantan | 272.97 | 45.38 |

| Ithusi | 10.09 | 1.678 |

| Insimbi | 57.81 | 9.61 |

| Manganin | 290 | 48.21 |

| I-Molybdenum | 32.12 | 5.34 |

| I-Nichrome | 675 | 112.2 |

| UNichrome V | 650 | 108.1 |

| I-Nickel | 41.69 | 6.93 |

| IPlatinum | 63.16 | 10.5 |

| Insimbi engagqwali (304) | 541 | 90 |

| Insimbi (0.5% carbon) | 100 | 16.62 |

| Zinc | 35.49 | 5.90 |