I-Spiral Electric Resistor CuNi Alloy 1 – 5 Mohm Yezinto Zokushisa Ezisebenzisa I-Air Conditioner

I-Spiral Electric Resistor Nicr Alloy 1 – 5 Mohm Yezinto Zokushisa Ezisebenzisa I-Air Conditioner

1. Incazelo Ejwayelekile Yezinto Ezibalulekile

I-Constantaniyi-alloy yethusi-nickel eyaziwa nangokuthiI-Eureka,Ngaphambi kwesikhathi, futhiIsikebheNgokuvamile iqukethe ithusi elingu-55% kanye ne-nickel engu-45%. Isici sayo esiyinhloko ukumelana kwayo, okungaguquguquki emazingeni okushisa ahlukahlukene. Amanye ama-alloy ane-coefficients yokushisa ephansi efanayo ayaziwa, njenge-manganin (Cu).86Mn12Ni2).

Ukuze kulinganiswe izinhlobo ezinkulu kakhulu, ezingama-5% (50 000 microstrian) noma ngaphezulu, i-annealed constantan (i-P alloy) iyinto yegridi evame ukukhethwa. I-Constantan kuleli fomu ilula kakhulu.i-ductilefuthi, ngobude begeyiji obungu-0.125 inches (3.2 mm) nangaphezulu, kungacindezelwa kufike ku->20%. Nokho, kufanele kukhunjulwe ukuthi ngaphansi kobunzima obuphezulu be-cyclic i-P alloy izobonisa ushintsho oluthile lokumelana okungapheli ngomjikelezo ngamunye, futhi ibangele okuhambisanayo.u-zeroukushintsha kwesilinganiso sokucindezeleka. Ngenxa yalesi sici, kanye nokuthambekela kokwehluleka kwegridi ngaphambi kwesikhathi ngokucindezelwa okuphindaphindiwe, i-P alloy ayinconywa ngokuvamile ekusetshenzisweni kokucindezeleka okujikelezayo. I-P alloy iyatholakala ngezinombolo ze-STC ezingu-08 no-40 ukuze zisetshenziswe ezinsimbini nasepulasitikini, ngokulandelana.

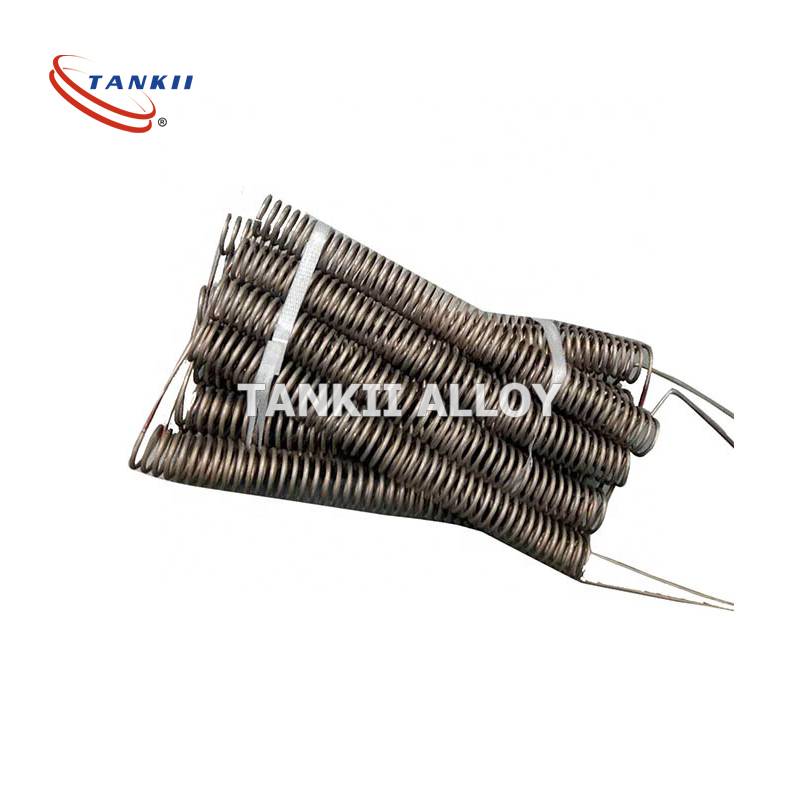

2. Isingeniso saseNtwasahlobo kanye nezicelo

Intwasahlobo yokudonsa ejikelezayo, noma intwasahlobo yezinwele, ewashini le-alamu.

Isipilingi esinomoya opholile. Ngaphansi kokucindezelwa, ama-coil ayashelelana, okwenza kube lula ukuhamba isikhathi eside.

Iziphethu ze-volute eziqondile zethangi likaStuart

Iziphethu zokucindezela kudivayisi yokubuyisa umugqa ogoqiwe.

Ibha yokugoba ejijekile ngaphansi komthwalo

Intwasahlobo yeqabunga elolini

Iziphethu zingahlukaniswa ngokuya ngokuthi amandla omthwalo asetshenziswa kanjani kuzo:

Intwasahlobo yokucindezela/yokwandisa – intwasahlobo yenzelwe ukusebenza ngomthwalo wokucindezela, ngakho intwasahlobo iyanwebeka njengoba umthwalo ufakwa kuyo.

Intwasahlobo yokucindezela – yenzelwe ukusebenza ngomthwalo wokucindezela, ngakho-ke intwasahlobo iba mfushane njengoba umthwalo ufakwa kuyo.

Intwasahlobo yokugoqa – ngokungafani nezinhlobo ezingenhla lapho umthwalo ungamandla aqondile, umthwalo osetshenziswa esiphethwini sokugoqa uyi-torque noma amandla okujika, futhi ukuphela kwesiphethwini kuzungeza nge-engeli njengoba umthwalo usetshenziswa.

Umthwalo osekelwayo wentwasahlobo oqhubekayo uhlala ufana phakathi nomjikelezo wokuphambuka.

Intwasahlobo eguquguqukayo – ukumelana kwekhoyili ekulayisheni kuyahlukahluka ngesikhathi sokucindezelwa.

Intwasahlobo yokuqina eguquguqukayo – ukumelana kwekhoyili ukulayisha kungashintshwa ngokuguquguqukayo isibonelo uhlelo lokulawula, ezinye izinhlobo zalezi zintwasahlobo nazo ziyahlukahluka ubude bazo ngaleyo ndlela zinikeze nekhono lokuqalisa.

Zingahlukaniswa futhi ngokususelwa ekubunjweni kwazo:

Intwasahlobo eyisicaba – lolu hlobo lwenziwe ngensimbi yentwasahlobo esiyisicaba.

Intwasahlobo emshinini – lolu hlobo lwentwasahlobo lukhiqizwa nge-machining bar stock ene-lathe kanye/noma i-milling operation esikhundleni sokusebenza nge-coiling. Njengoba imshinini, intwasahlobo ingafaka izici ngaphezu kwe-elastic element. Intwasahlobo emshinini ingenziwa ezimweni zomthwalo ojwayelekile wokucindezela/ukwandisa, i-torsion, njll.

Isiphethu senyoka – ucingo olujiyile olugobile – oluvame ukusetshenziswa ezindlini zokuhlobisa/ifenisha yesimanje.

3. Ukwakheka Kwamakhemikhali kanye Nempahla Eyinhloko Ye-Cu-Ni Low Resistance Alloy

| I-PropertiesGrade | I-CuNi1 | I-CuNi2 | I-CuNi6 | I-CuNi8 | I-CuMn3 | I-CuNi10 | |

| Ukwakheka Okuyinhloko Kwamakhemikhali | Ni | 1 | 2 | 6 | 8 | _ | 10 |

| Mn | _ | _ | _ | _ | 3 | _ | |

| Cu | I-Bal | I-Bal | I-Bal | I-Bal | I-Bal | I-Bal | |

| Izinga Lokushisa Eliphezulu Lesevisi Eqhubekayo (oC) | 200 | 200 | 200 | 250 | 200 | 250 | |

| Ukuqina kokushisa ku-20oC (Ωmm2/m) | 0.03 | 0.05 | 0.10 | 0.12 | 0.12 | 0.15 | |

| Ubuningi (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.8 | 8.9 | |

| Ukushisa Okushisayo (α×10-6/oC) | <100 | <120 | <60 | <57 | <38 | <50 | |

| Amandla Okudonsa (i-Mpa) | ≥210 | ≥220 | ≥250 | ≥270 | ≥290 | ≥290 | |

| I-EMF vs Cu(μV/oC)(0~100oC) | -8 | -12 | -12 | -22 | _ | -25 | |

| Isilinganiso Sokuncibilika (oC) | 1085 | 1090 | 1095 | 1097 | 1050 | 1100 | |

| Isakhiwo se-Micrographic | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | |

| Impahla Kamagnetic | hhayi | hhayi | hhayi | hhayi | hhayi | hhayi | |

| I-PropertiesGrade | I-CuNi14 | I-CuNi19 | I-CuNi23 | I-CuNi30 | I-CuNi34 | I-CuNi44 | |

| Ukwakheka Okuyinhloko Kwamakhemikhali | Ni | 14 | 19 | 23 | 30 | 34 | 44 |

| Mn | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| Cu | I-Bal | I-Bal | I-Bal | I-Bal | I-Bal | I-Bal | |

| Izinga Lokushisa Eliphezulu Lesevisi Eqhubekayo (oC) | 300 | 300 | 300 | 350 | 350 | 400 | |

| Ukuqina kokushisa ku-20oC (Ωmm2/m) | 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.49 | |

| Ubuningi (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| Ukushisa Okushisayo (α×10-6/oC) | <30 | <25 | <16 | <10 | <0 | <-6 | |

| Amandla Okudonsa (i-Mpa) | ≥310 | ≥340 | ≥350 | ≥400 | ≥400 | ≥420 | |

| I-EMF vs Cu(μV/oC)(0~100oC) | -28 | -32 | -34 | -37 | -39 | -43 | |

| Isilinganiso Sokuncibilika (oC) | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| Isakhiwo se-Micrographic | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | |

| Impahla Kamagnetic | hhayi | hhayi | hhayi | hhayi | hhayi | hhayi | |

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu