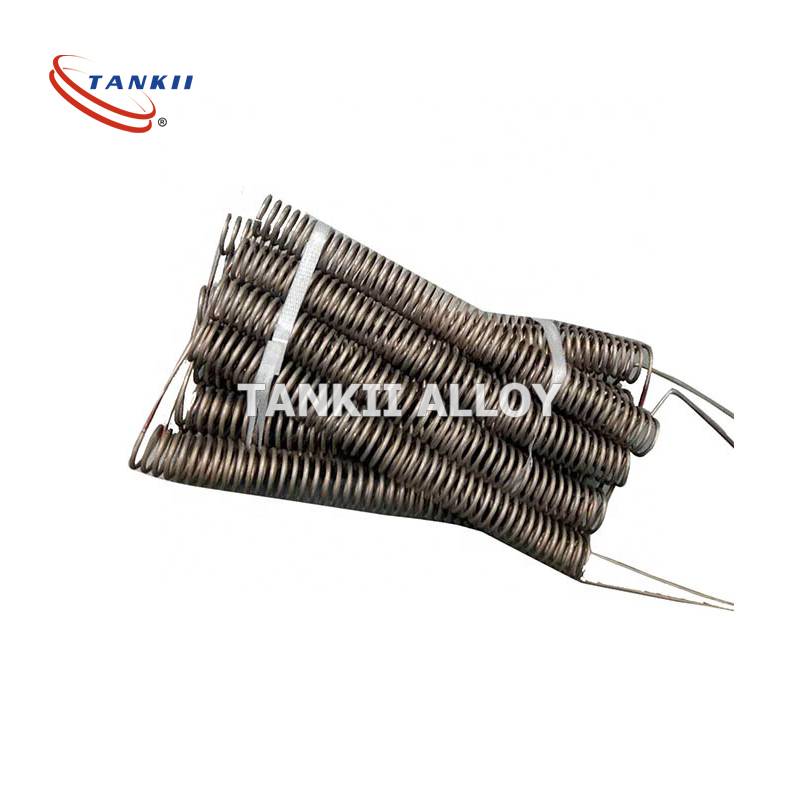

I-Spiral Electric Resistor CuNi Alloy 1 – 5 Mohm Yezinto Zokushisisa I-Air Conditioner

I-Spiral Electric Resistor i-Nicr Alloy 1 – 5 Mohm Yezinto Zokushisisa I-Air Conditioner

1.Incazelo Yezinto Ezivamile

Constantaniyingxubevange yethusi-nickel eyaziwa nangokuthiEureka,Phambili, futhiIsikebhe.Ngokuvamile iqukethe u-55% wethusi no-45% we-nickel.Isici sawo esiyinhloko yi-resistivity yayo, ehlala njalo phezu kwezinhlobonhlobo zamazinga okushisa.Amanye ama-alloy anama-coefficients okushisa aphansi afanayo ayaziwa, njenge-mangan (Cu86Mn12Ni2).

Esilinganisweni sezinhlobo ezinkulu kakhulu, u-5% (50 000 microstrian) noma ngaphezulu, i-annealed constantan (P alloy) yinto yegridi evame ukukhethwa.Constantan kuleli fomu kakhului-ductile;futhi, ku-gauge yobude obungu-0.125 amayintshi (3.2 mm) nangaphezulu, ingafakwa ku->20%.Kufanele kukhunjulwe, nokho, ukuthi ngaphansi kwezinhlobo eziphakeme zama-cyclic ingxubevange ye-P izokhombisa ushintsho oluthile lokumelana unomphela ngomjikelezo ngamunye, futhi ibangele okuhambisanayo.uziroukushintsha kwe-strain gauge.Ngenxa yalesi sici, kanye nokuthambekela kokuhluleka kwegridi ngaphambi kwesikhathi ngokuqina okuphindaphindiwe, i-P alloy ayinconywa ngokujwayelekile ezinhlelweni zohlobo lwe-cyclic.I-P ingxubevange iyatholakala nezinombolo ze-STC ezingu-08 no-40 ukuze zisetshenziswe ezinsimbi namapulasitiki, ngokulandelana.

2. Isingeniso Sentwasahlobo kanye nezicelo

Isiphethu se-torsion spiral, noma i-hairspring, ewashini le-alamu.

Intwasahlobo evulekile.Ngaphansi kokucindezelwa amakhoyili ayashelela phezu kwelinye, ukuze akwazi ukuhamba isikhathi eside.

Iziphethu zevolute eziqondile ze-Stuart tank

Ukushuba kuqhamuka emshinini ogoqiwe wokuguqula umugqa.

I-torsion bar esontekile ngaphansi komthwalo

Iqabunga liphuma elolini

Iziphethu zingahlukaniswa kuye ngokuthi amandla omthwalo asetshenziswa kanjani kuzo:

I-Tension/extension spring - intwasahlobo iklanyelwe ukusebenza ngomthwalo we-tension, ngakho-ke intwasahlobo iyanwebeka njengoba umthwalo usetshenziswa kuwo.

Intwasahlobo yokucindezela - iklanyelwe ukusebenza ngomthwalo wokucindezela, ngakho-ke intwasahlobo iba mfushane njengoba umthwalo usetshenziswa kuwo.

I-Torsion spring - ngokungafani nezinhlobo ezingenhla lapho umthwalo ungamandla e-axial, umthwalo osetshenziswa emthonjeni we-torsion uyi-torque noma amandla aphikisayo, futhi ukuphela kwentwasahlobo kujikeleza nge-angle njengoba umthwalo usetshenziswa.

Intwasahlobo eqhubekayo - umthwalo osekelwayo uhlala unjalo kuwo wonke umjikelezo wokuchezuka.

Intwasahlobo eguquguqukayo - ukumelana kwekhoyili ukulayisha kuyahlukahluka ngesikhathi sokucindezelwa.

Ukuqina okuguquguqukayo kwentwasahlobo - ukumelana kwekhoyili ukulayisha kungashintshashintsha ngokwesibonelo ngesistimu yokulawula, ezinye izinhlobo zalezi ziphethu nazo ziyashintsha ubude bazo ngaleyo ndlela zinikeze amandla okusebenza futhi.

Futhi zingahlukaniswa ngokuya ngesimo sazo:

Intwasahlobo eyisicaba - lolu hlobo lwenziwe ngensimbi eyisicaba.

Intwasahlobo eyenziwe ngomshini - lolu hlobo lwentwasahlobo lukhiqizwa isitokwe sebha yomshini nge-lathe kanye/noma umsebenzi wokugaya esikhundleni sokusebenza kokugoqa.Njengoba yenziwe ngomshini, intwasahlobo ingase ihlanganise izici ngaphezu kwesici esinwebekayo.Iziphethu ezenziwe ngomshini zingenziwa ezimweni ezijwayelekile zokulayisha zokucindezelwa/isandiso, ukukhwehlela, njll.

Intwasahlobo yenyoka - i-zig-zag yocingo oluwugqinsi - evame ukusetshenziswa ku-upholstery / ifenisha yesimanje.

3.Ukwakheka Kwekhemikhali kanye Nempahla Eyinhloko ye-Cu-Ni Low Resistance Alloy

| PropertiesGrade | KuNi1 | KuNi2 | Kuni6 | Kunini8 | CuMn3 | KuNi10 | |

| Ukwakheka Kwamakhemikhali Okuyinhloko | Ni | 1 | 2 | 6 | 8 | _ | 10 |

| Mn | _ | _ | _ | _ | 3 | _ | |

| Cu | U-Bal | U-Bal | U-Bal | U-Bal | U-Bal | U-Bal | |

| I-Max Continuous Service Temperature(oC) | 200 | 200 | 200 | 250 | 200 | 250 | |

| I-Resisivity ku-20oC (Ωmm2/m) | 0.03 | 0.05 | 0.10 | 0.12 | 0.12 | 0.15 | |

| Ukuminyana(g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.8 | 8.9 | |

| I-Thermal Conductivity(α×10-6/oC) | <100 | <120 | <60 | <57 | <38 | <50 | |

| Amandla Okuqina (Mpa) | ≥210 | ≥220 | ≥250 | ≥270 | ≥290 | ≥290 | |

| I-EMF vs Cu(μV/oC)(0~100oC) | -8 | -12 | -12 | -22 | _ | -25 | |

| I-approximate Melting Point(oC) | 1085 | 1090 | 1095 | 1097 | 1050 | 1100 | |

| Isakhiwo seMicrographic | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | |

| Impahla Magnetic | hhayi | hhayi | hhayi | hhayi | hhayi | hhayi | |

| PropertiesGrade | CuNi14 | Kunini19 | KuNi23 | KuNi30 | CuNi34 | ICuNi44 | |

| Ukwakheka Kwamakhemikhali Okuyinhloko | Ni | 14 | 19 | 23 | 30 | 34 | 44 |

| Mn | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| Cu | U-Bal | U-Bal | U-Bal | U-Bal | U-Bal | U-Bal | |

| I-Max Continuous Service Temperature(oC) | 300 | 300 | 300 | 350 | 350 | 400 | |

| I-Resisivity ku-20oC (Ωmm2/m) | 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.49 | |

| Ukuminyana(g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| I-Thermal Conductivity(α×10-6/oC) | <30 | <25 | <16 | <10 | <0 | <-6 | |

| Amandla Okuqina (Mpa) | ≥310 | ≥340 | ≥350 | ≥400 | ≥400 | ≥420 | |

| I-EMF vs Cu(μV/oC)(0~100oC) | -28 | -32 | -34 | -37 | -39 | -43 | |

| I-approximate Melting Point(oC) | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| Isakhiwo seMicrographic | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | i-austenite | |

| Impahla Magnetic | hhayi | hhayi | hhayi | hhayi | hhayi | hhayi | |