Ikhoyili Yentwasahlobo

pincazelo yomkhiqizo

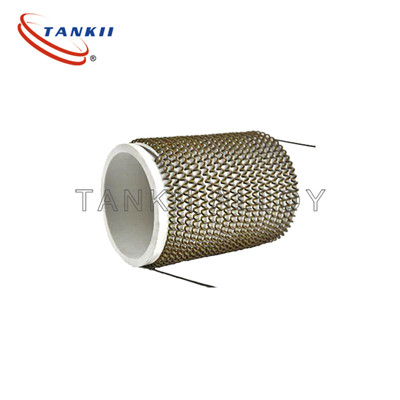

Inkampani yethu ikhiqiza izintambo zokushisa zikagesi ze-iron-chromium-aluminium kanye ne-nickel-chromium ezisezingeni eliphezulu, ezisebenzisa amandla entambo yesithando somlilo esilawulwa yikhompyutha futhi zihlanganiswa zibe yisimo somshini wokugoqa ozenzakalelayo osheshayo. Izici zalo mkhiqizo: ukumelana nokushisa okuphezulu, ukushisa okusheshayo, impilo yesevisi ende, ukumelana okuzinzile, ukuphambuka kwamandla amancane, iphimbo elifanayo ngemva kokwelula, indawo ekhanyayo nehlanzekile; esetshenziswa kabanzi ezithandweni zikagesi ezincane, ezithandweni zomlilo, imishini yokushisa kanye neyomoya opholile, ohhavini abahlukahlukene, amashubhu okushisa kagesi kanye nezinto zasekhaya, njll. Imigoqo ehlukahlukene yezithando zomlilo yezimboni neyezomphakathi ingaklanywa futhi ikhiqizwe ngokwezidingo zomsebenzisi.

| Amandla W | Vi-oltage V | Ububanzi mm | OD mm | Li-ength (Ireferensi) mm | Wamagremu ayisishiyagalombili |

| 300 | 220 | 0.25 | 3.7 | 122 | 1.9 |

| 500 | 220 | 0.35 | 3.9 | 196 | 4.3 |

| 600 | 220 | 0.40 | 4.2 | 228 | 6.1 |

| 800 | 220 | 0.50 | 4.7 | 302 | 11.1 |

| 1000 | 220 | 0.60 | 4.9 | 407 | 18.5 |

| 1200 | 220 | 0.70 | 5.6 | 474 | 28.5 |

| 1500 | 220 | 0.80 | 5.8 | 554 | 39.0 |

| 2000 | 220 | 0.95 | 6.1 | 676 | 57.9 |

| 2500 | 220 | 1.10 | 6.9 | 745 | 83.3 |

| 3000 | 220 | 1.20 | 7.1 | 792 | 98.3 |

Izinga lokushisa kanye nokwakheka kwamakhemikhali kwentambo yokushisa

| Ibanga | Ubuningi. Kuyaqhubeka Isimo Sokusebenza. | I-Cr% | I-Ni% | I-Al% | I-Fe% | I-Re% | I-Nb% | Inyanga% |

| I-Cr20Ni80 | 1200℃ | 20~23 | Ibhalansi. |

|

|

|

|

|

| I-Cr30Ni70 | 1250℃ | 28~31 | Ibhalansi. |

|

|

|

|

|

| I-Cr15Ni60 | 1150℃ | 15~18 | 55~61 |

| Ibhalansi. |

|

|

|

| I-Cr20Ni35 | 1100℃ | 18~21 | 34~37 |

| Ibhalansi. |

|

|

|

| I-TANKII APM | 1425℃ | 20.5~23.5 |

| 5.8 | Ibhalansi. | / |

|

|

| 0Cr27Al7Mo2 | 1400℃ | 26.5~27.8 |

| 6~7 | Ibhalansi. |

|

| 2 |

| 0Cr21Al6Nb | 1350℃ | 21~23 |

| 5~7 | Ibhalansi. |

| 0.5 |

|

| 0Cr25Al5 | 1250℃ | 23~26 |

| 4.5~6.5 | Ibhalansi. |

|

|

|

| 0Cr23Al5Y | 1300℃ | 22.5~24.5 |

| 4.2~5.0 | Ibhalansi. |

|

|

|

| 0Cr19Al3 | 1100℃ | 18~21 |

| 3~4.2 | Ibhalansi. |

|

|

|

Izakhiwo zobuchwepheshe eziyinhloko zentambo ye-FeCrAl alloy:

①Izinga lokushisa lokusebenzisa liphezulu, izinga lokushisa lokusebenzisa ucingo lwe-aluminium alloy lwensimbi-chromium emoyeni lingafinyelela ku-1300℃;

②Impilo yesevisi ende;

③Umthwalo ovumelekile wobuso mkhulu;

⑤Isisindo esiqondile sincane kune-nickel-chromium alloy; ④Ukumelana nokushiswa kwe-oxidation kuhle, futhi ifilimu ye-AI2O3 eyakhiwe ngemuva kokushiswa kwe-oxidation inokumelana okuhle kwamakhemikhali kanye nokumelana okuphezulu;

⑥Ukumelana okuphezulu;

⑦Ukumelana okuhle nesibabule;

⑧Intengo iphansi kakhulu kuneye-nickel-chromium alloy;

⑨Ububi ukuthi njengoba izinga lokushisa likhuphuka, libonisa ukuqina, futhi amandla emazingeni okushisa aphezulu aphansi.

Izici zentambo yesitofu sikagesi se-nickel-chromium yilezi:

① Amandla aphezulu ekushiseni okuphezulu;

②Uma ipholile ngemva kokusetshenziswa isikhathi eside, izinto ngeke ziqhekeke;

③Ukukhishwa kwe-alloy ye-Ni-ming egcwele i-oxidized kuphakeme kunokwe-alloy ye-Fe-Cr-Al;

④Akukho ukuzikhandla;

⑤Ngaphandle kwesimo sezulu sesibabule, sinokumelana okungcono kokugqwala

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu