Ikhoyili Yokugoba yentambo yokumelana ne-FeCrAl engu-0.05mm Ubude

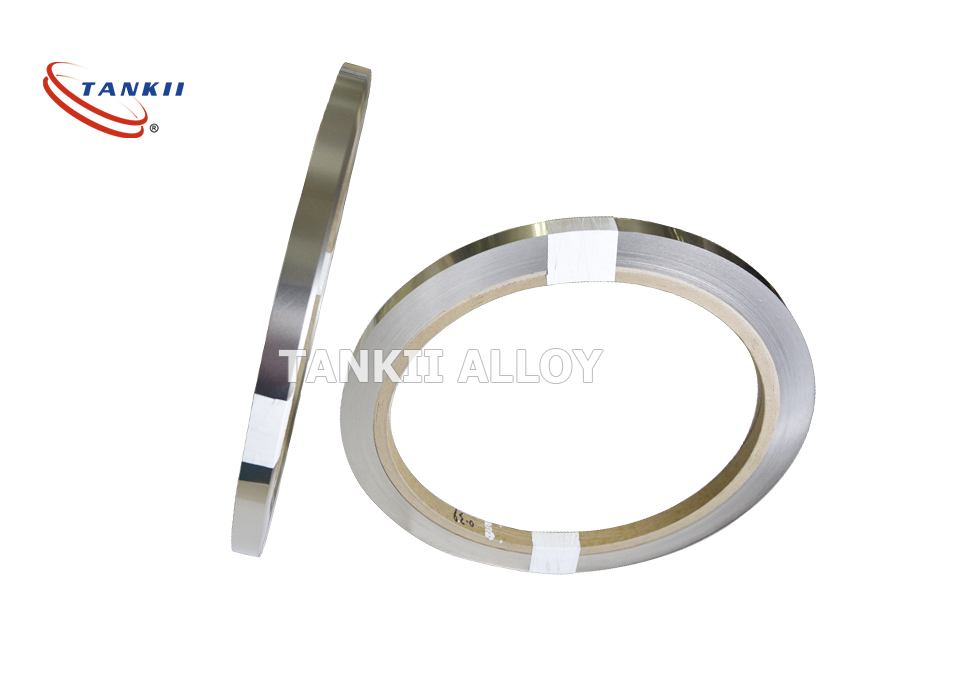

I-FeCrAl AlloyIkhoyili ye-Foil/Strip engu-0.05mm Ubukhulu be-Substrate ye-Honeycomb yensimbi

Okuqukethwe okuphezulu kwe-aluminium, kuhlangene nokuqukethwe okuphezulu kwe-chromium kubangela ukuthi izinga lokushisa lokulinganisa lenyuke lifike ku-1425 C (2600F); Ngaphansi kwesihloko esikhulu ukumelana nokushisa, lokhuIngxubevange ye-FeCrAlAma-s aqhathaniswa nama-alloy esisekelo e-Fe ne-Ni asetshenziswa njalo. Njengoba kungabonakala kulelo thebula,Ingxubevange ye-FeCrAlama-s anezakhiwo ezinhle kakhulu uma kuqhathaniswa nezinye izinhlobo ze-alloy ezindaweni eziningi.

Kufanele kuqashelwe ukuthi, ngesikhathi sezimo zokushisa ezishintshanayo, ukwengezwa kwe-yttrium ku-alloy ye-AF eyaziwa nangokuthi ama-alloy e-Fecralloys, kuthuthukisa ukunamathela kwe-oxide evikelayo, okwenza impilo yenkonzo yezingxenye ku-alloy ye-AF ibe yinde kuneyebanga le-A-1.

Izintambo ze-Fe-Cr-Al alloy zenziwe ngama-alloy e-aluminium ensimbi aqukethe inani elincane lezinto ezisebenzayo njenge-yttrium ne-zirconium futhi zikhiqizwa ngokuncibilikisa, ukugoqa insimbi, ukwakheka, ukunamathisela, ukudweba, ukwelashwa kwendawo, ukuhlolwa kokulawula ukumelana, njll.

Intambo ye-Fe-Cr-Al yakhiwe ngomshini wokupholisa ozenzakalelayo osheshayo lapho amandla awo alawulwa yikhompyutha, atholakala njengocingo kanye neribhoni (umcu).

Izici nezinzuzo

1. Izinga lokushisa eliphezulu lokusebenzisa, izinga lokushisa eliphezulu lokusebenzisa lingafinyelela ku-1400C (0Cr21A16Nb, 0Cr27A17Mo2, njll.)

2. Isilinganiso sokumelana nokushisa okuphansi

3. I-coefficient yokwandisa ukushisa ephansi kune-Ni-base super-alloys.

4. Ukumelana okuphezulu kukagesi

5. Ukumelana okuhle nokugqwala ngaphansi kokushisa okuphezulu, ikakhulukazi ngaphansi komkhathi oqukethe ama-sulfide

6. Umthwalo ophezulu wobuso

7. Ayikwazi ukukhukhuleka

8. Izindleko eziphansi zezinto zokusetshenziswa, Ubuningi obuphansi kanye nentengo eshibhile uma kuqhathaniswa ne-Nichrome wire.

9. Ukumelana okuphezulu kwe-oxidation ku-800-1300ºC

10. Impilo ende yenkonzo

Ukwakheka kwezigaba ze-alumina eziguquguqukayo ngenxa yokushiswa kwezamabhizinisiIngxubevange ye-FeCrAlKuhlolwe izintambo (ubukhulu obungu-0.5 mm) emazingeni okushisa ahlukahlukene kanye nezikhathi. Amasampula ahlaziywe nge-isothermally emoyeni kusetshenziswa i-thermogravimetric analyzer (TGA). Ukwakheka kwamasampula ahlaziywe kwahlaziywa kusetshenziswa i-Electronic Scanning Electron Microscope (ESEM) kanye ne-X-ray ekuhlaziyweni kobuso kwenziwa kusetshenziswa i-Energy Dispersive X-Ray (EDX) analyzer. Indlela ye-X-Ray Diffraction (XRD) yasetshenziswa ukuchaza isigaba sokukhula kwe-oxide. Lonke ucwaningo lubonise ukuthi kungenzeka ukukhulisa i-gamma alumina yendawo ephezulu endaweni ephezulu.Ingxubevange ye-FeCrAlizindawo zocingo lapho zishiswa nge-isothermally ngaphezu kuka-800°C emahoreni amaningana.

| I-Aluminium ye-Chrome yensimbi | |||||||

| I-OCr25Al5 | I-CrAl25-5 | 23.0 | 71.0 | 6.0 | |||

| I-OCr20Al5 | I-CrAl20-5 | 20.0 | 75.0 | 5.0 | |||

| OCr27Al7Mo2 | 27.0 | 65.0 | 0.5 | 7.0 | 0.5 | ||

| OCr21Al6Nb | 21.0 | 72.0 | 0.5 | 6.0 | 0.5 | ||

| I-Aluminium ye-Chrome yensimbi | ||

| I-OCr25Al5 | Ingasetshenziswa ezimweni zokusebenza ezifika ku-1350°C, yize ingaqhekeka. | Izinto zokushisa zama-furnace anokushisa okuphezulu kanye nama-heater akhanya kakhulu. |

| I-OCr20Al5 | Ingxubevange ye-ferromagnetic engasetshenziswa emazingeni okushisa afinyelela ku-1300°C. Kufanele isetshenziswe endaweni eyomile ukuze kugwenywe ukugqwala. Ingacwiliswa emazingeni okushisa aphezulu. | Izinto zokushisa zama-furnace anokushisa okuphezulu kanye nama-heater akhanya kakhulu. |

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

I-Whatsapp

-

I-WeChat

UJudy

150 0000 2421

-

Phezulu